Start with superior X-ray analysis

For nearly 15 years, Marel’s revolutionary SensorX technology has been the standard in hard contaminant detection, helping processors win the battle against food contamination.

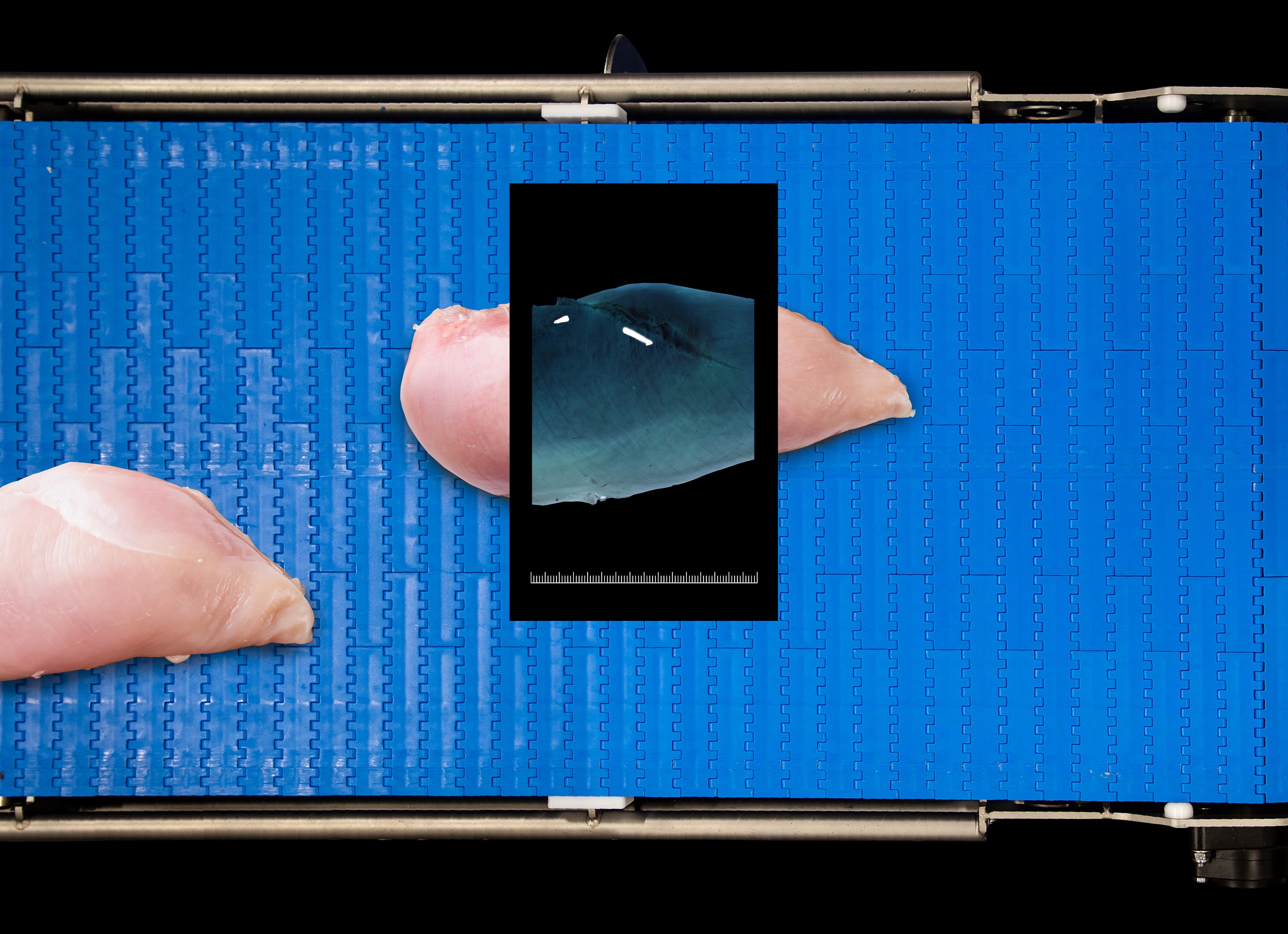

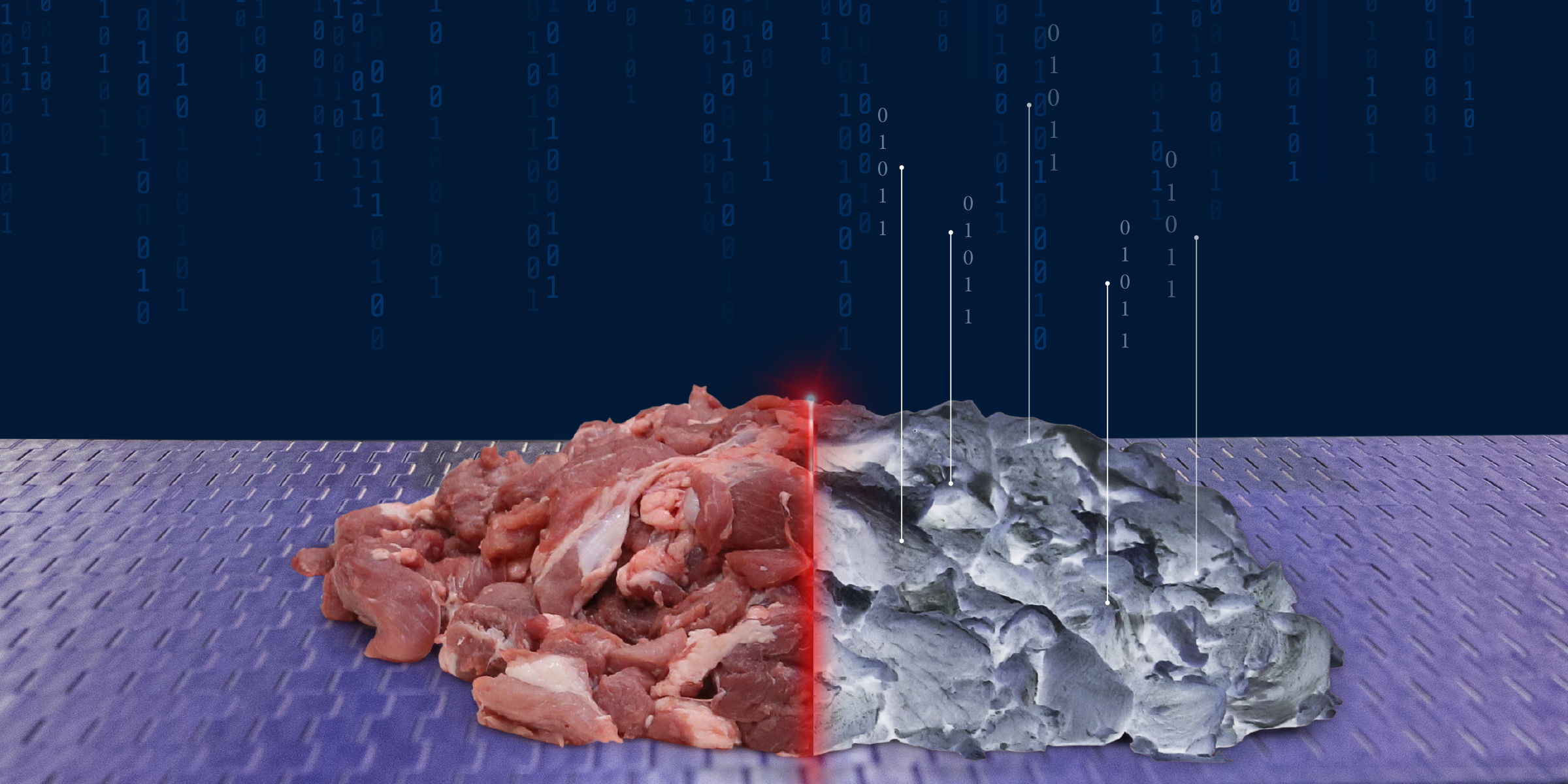

At the core of every SensorX system is Marel's industry-leading X-ray technology. It scans whole muscle and trim with unmatched accuracy to detect hard contaminants such as bone, metal and glass. SensorX can identify extremely small bone fragments with an extremely low false-positive rate.

The systems also allow processors to automate an array of time-consuming tasks and simultaneously pull valuable real-time production data, achieving greater accuracy and insight than could ever be possible manually.

In addition, SensorX significantly improves throughput and line efficiency. When BRF Thailand became the first poultry processor in the country to integrate SensorX technology in their lines, they immediately recognized the benefits.