Information

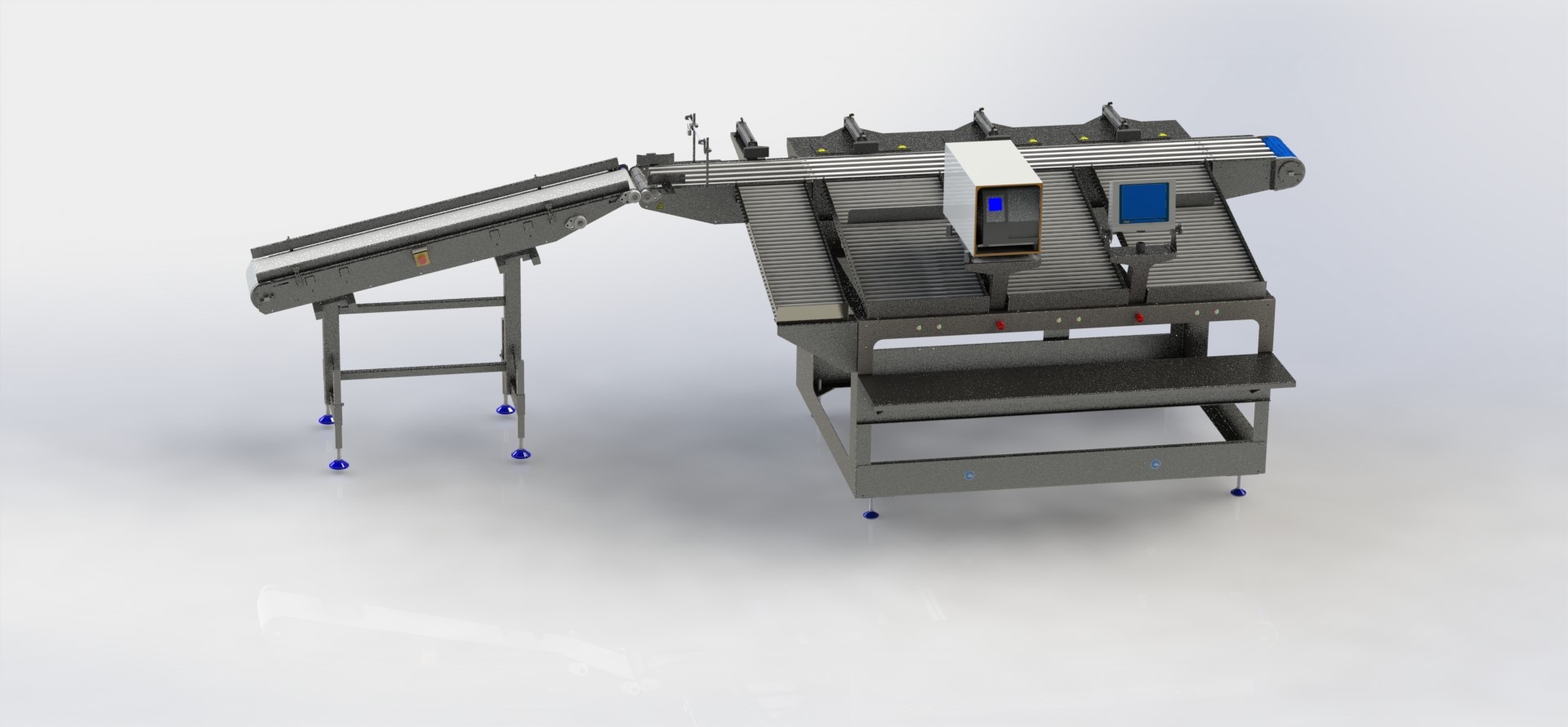

The TG9 Tray Grader grades trays by fixed count, fixed weight or a combination of both into boxes with totalized labels.

Fixed count mode

In fixed-count grading mode, the channels are filled according to a set-piece count. When the target count has been reached, the next channel starts filling and the operator can accept the batch and print a label for the batch. Alternatively, the operator can cancel the batch and utilize the reorder facility if needed.

Fixed weight mode

In fixed weight grading mode, a weigh price labeler – or another input device like a barcode scanner – captures and transmits weight, price and pack information to the grader. The TD9 then diverts each pack, according to its weight, into either one of its channels. Each channel collates the packs to reach the optimized target box weight.

Fixed count and weight

The TG9 allocates a set number of packs to each channel while selecting the channels according to weight to achieve the optimized target box weights. If a pack does not fit the requirement of any of the channels, it is diverted to the optional reject lane.

- Fixed-count grading mode

- Fixed-weight grading mode

- Combination of both fixed and count weight grading modes

- Totalized labels

Options

- Shutters

- Choice of either pushers or flippers

- Reject lane for simple reject of unsuitable packs

- Re-order lane to replace unsuitable packs

- Under conveyor for simple transportation of packed goods to palletizing area