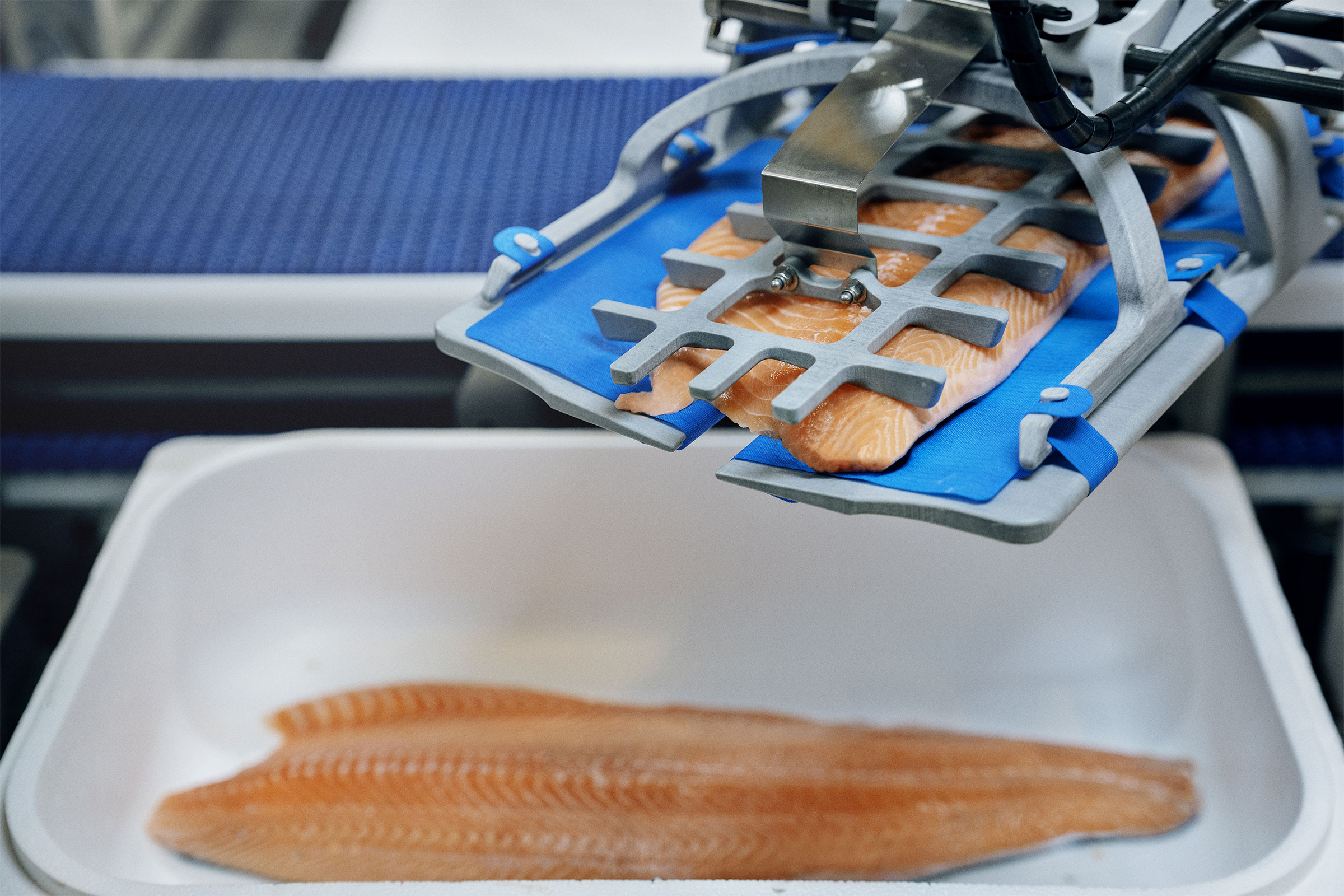

Groundbreaking automation in fish packing

Robotics are catapulting fish processing to an entirely new level of optimization and efficiency. Marel’s RoboBatcher Box revolutionizes the fish processing industry as the first and only robotic packing machine using intelligent batching technology. This level of automation benefits processors by not only significantly decreasing labor costs but also improving food safety, minimizing giveaway and virtually eliminating human error that may disrupt a production line.

Transforming the way fish is packed

With unprecedented speed and accuracy, the RobotBatcher Box automatically packs and styles up to 24 boxes simultaneously, with up to 12 different predefined jobs, into polystyrene and cardboard boxes. Whether you are looking to pack skin on skin or meat on meat, the intelligent grippers have the capacity to flip the fillets according to customer requirements. The RoboBatcher Box is unmatched in its ability to boost profitability by reducing giveaway, increasing product utilization and saving labor.