Information

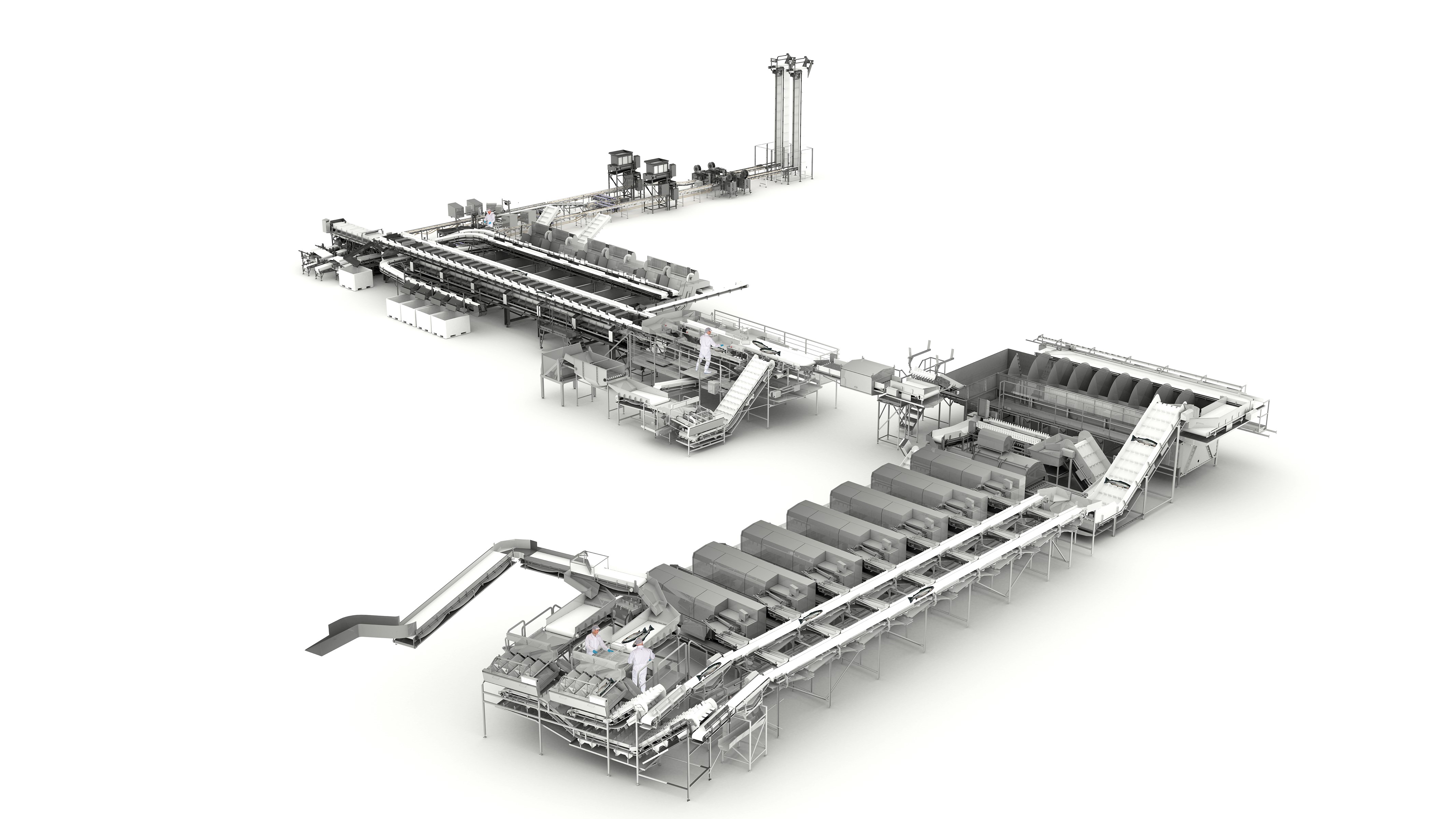

With the highly innovative and automated process, whole salmon flow seamlessly from slaughtering to processing and final dispatch. The system’s flexible processing capacity means processors can manage seasonal and order highs and lows without the pressure to increase or decrease their workforce.

The system covers the infeed for the gutting, along with distribution, grading and the packing after gutting. After the fish have been gutted, they enter the distribution system for individually weighing and quality grading. The fish are then delivered to the packing grader where they are automatically packed into boxes according to weight, quality, and orders, or delivered into the fillet processing area. With single or dual-lane options available, processors can be sure of high throughput and flexibility to adjust systems as needed.

Marel offers two optional solutions for manual infeed in front of the packing grader, either with inline or sideload infeed. At the infeed stations operators can inspect the fish before feeding them into the packing grader.