Information

Bone detection and grading in one

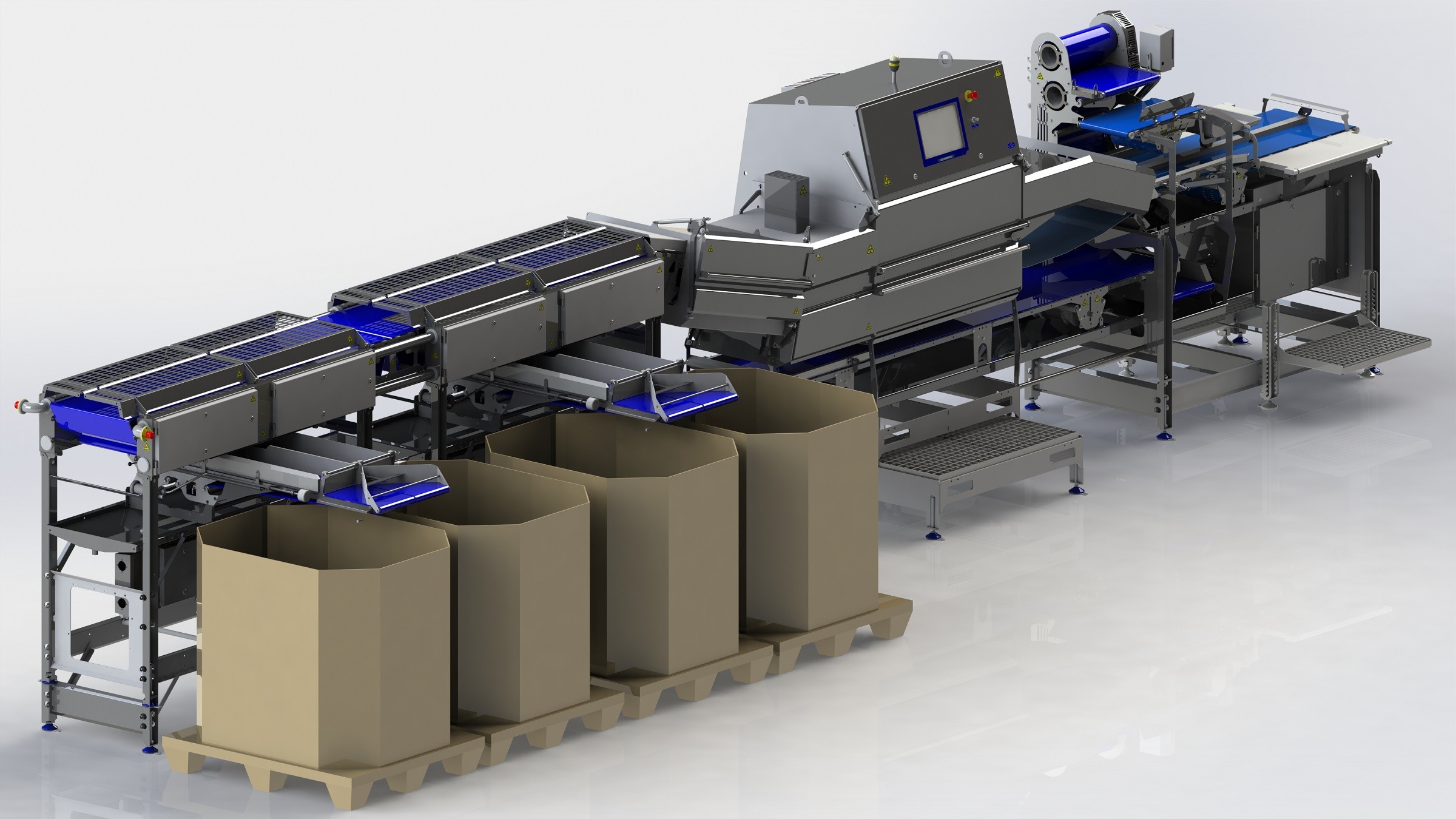

The SensorX bone detection system performs weighing using X-ray. The SmartSort is a discharge unit that can be positioned after the SensorX bone detection system. Together, the SensorX and SmartSort, with its unrivaled small floor footprint combine X-ray bone detection and grading in one compact solution.

The compact grading solution

The SmartSort gently diverts product into a crate, box or combo, or onto a conveyor based on weight. It uses the weight information from the SensorX so there is no need for a dynamic weighing unit. The SmartSort requires less product separation than a traditional grader, so it can perform grading at slower speeds, without the need for a speed-up belt. All in very compact form with small footprint.

Food safety and quality

With its superior bone detection, grading and less product handling the combined solution of SensorX and SmartSort ultimately delivers a safer, more valuable product.

Applications

The SensorX SmartSort solution is ideal for size grading, simple batching or dividing products into different processes.