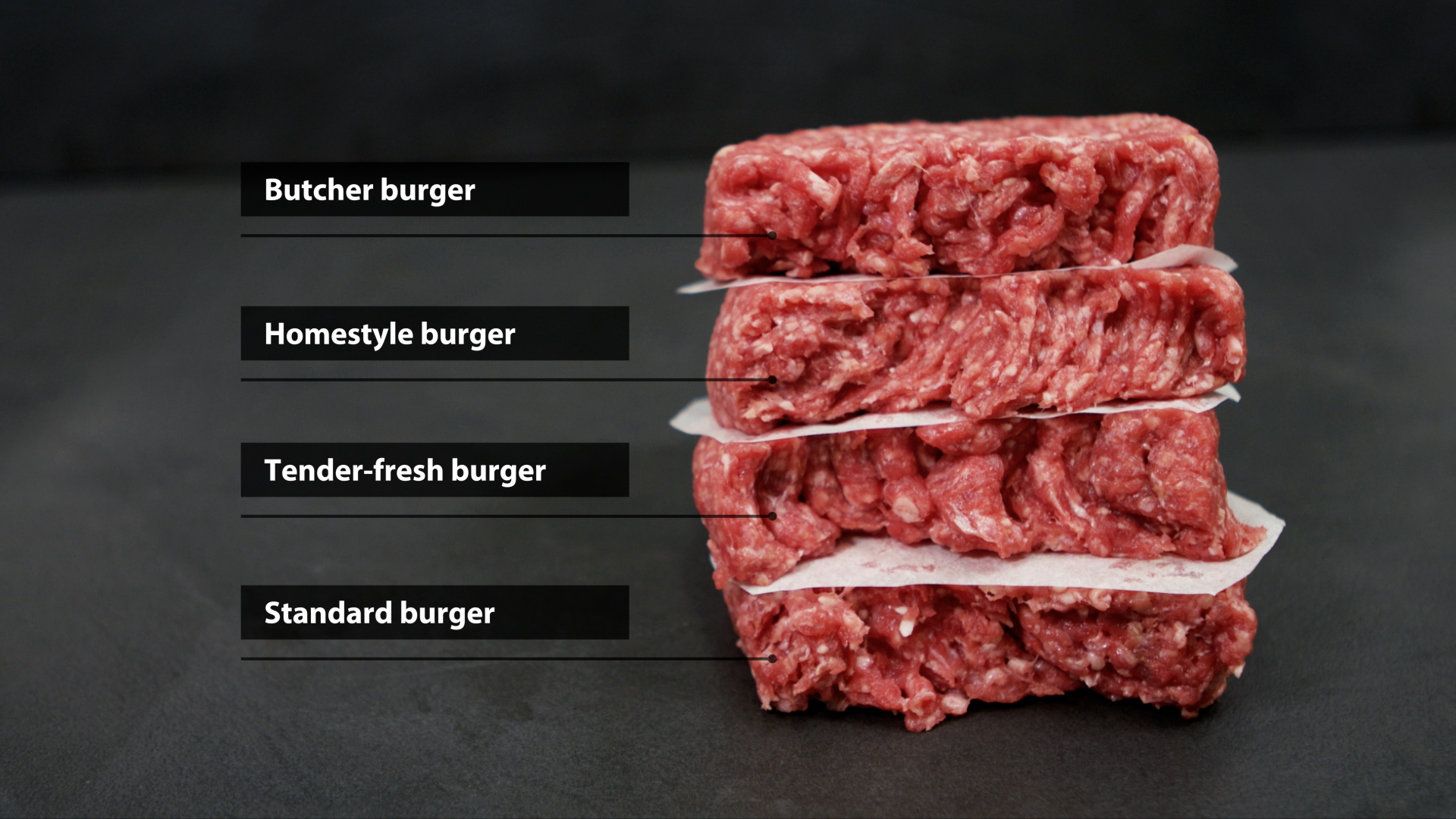

Working closely with you, we find the best way possible to create your required product. We do this by applying our deep-rooted knowledge of food technology and in-depth understanding of further processing.

Everything we do is based on a strong partnership with our customers. We work with you to set ambitious goals, from which we develop the solutions to meet your needs and product specifications.

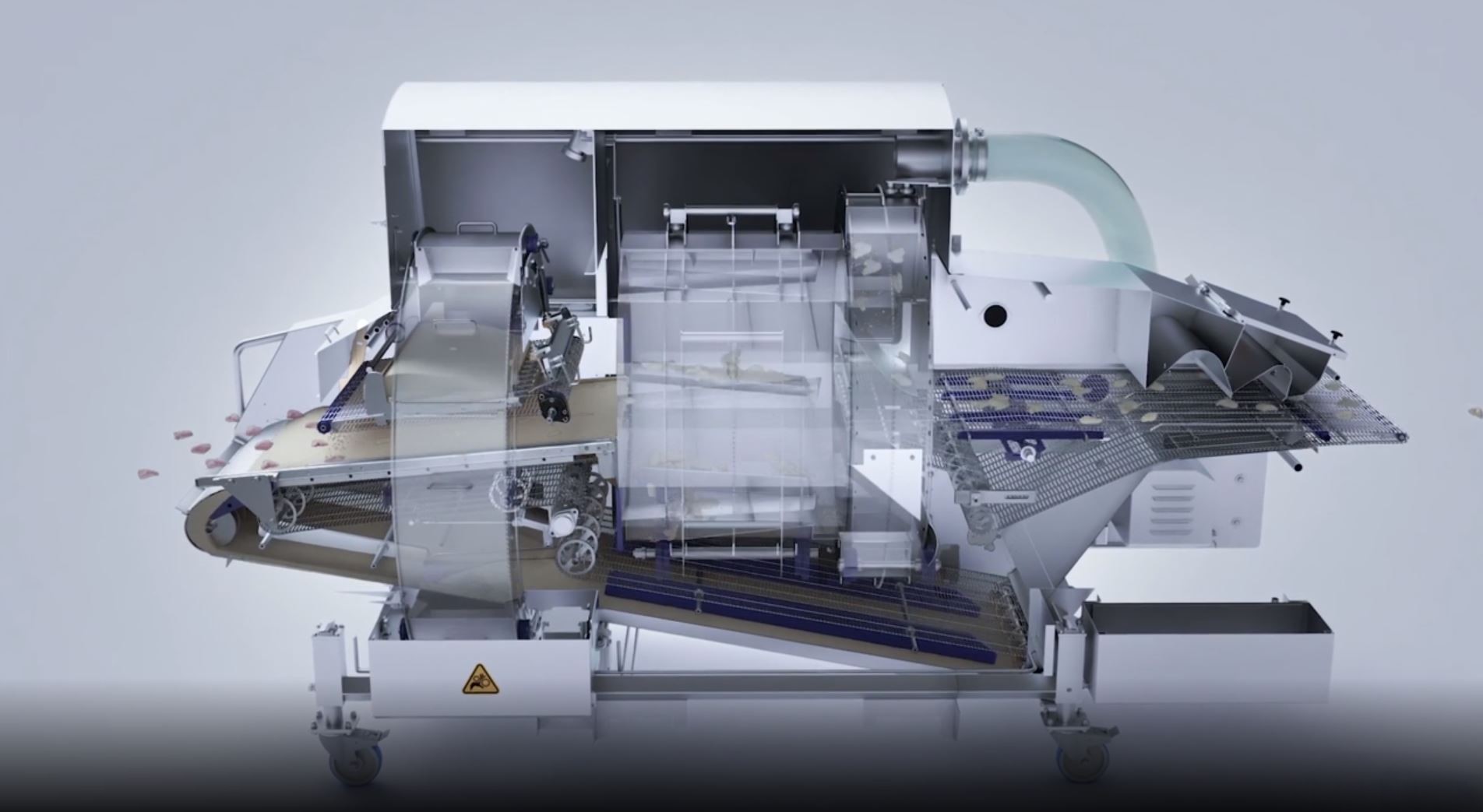

Whether you’re producing, convenience products, sausages, potato specialties or plant-based products we have a state-of-the-art solution to help you achieve the highest quality results.