The three products serve very distinct purposes, but all are examples of how Marel is leading the way in smarter processing solutions for the seafood industry.

Steady infeed for filleting lines

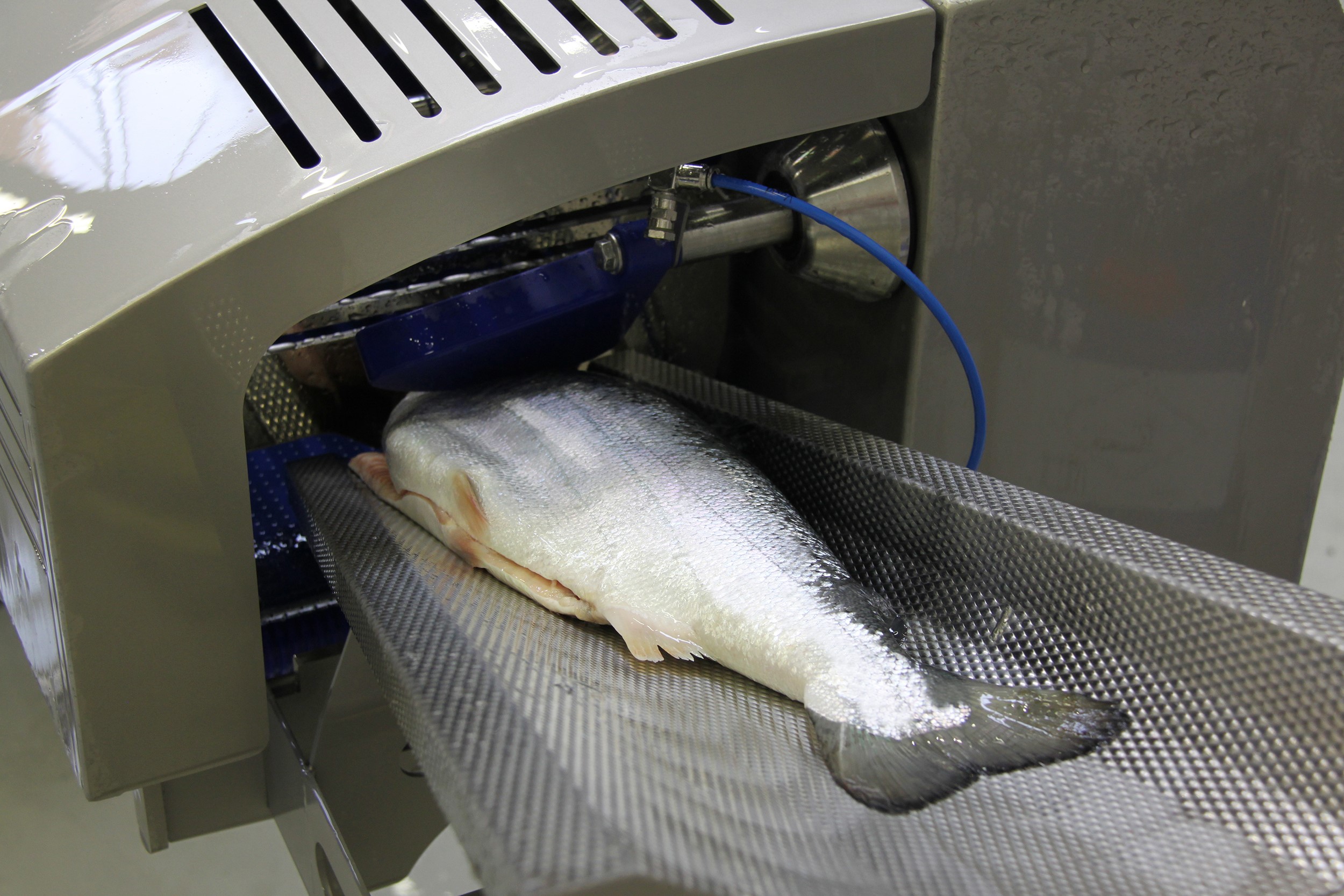

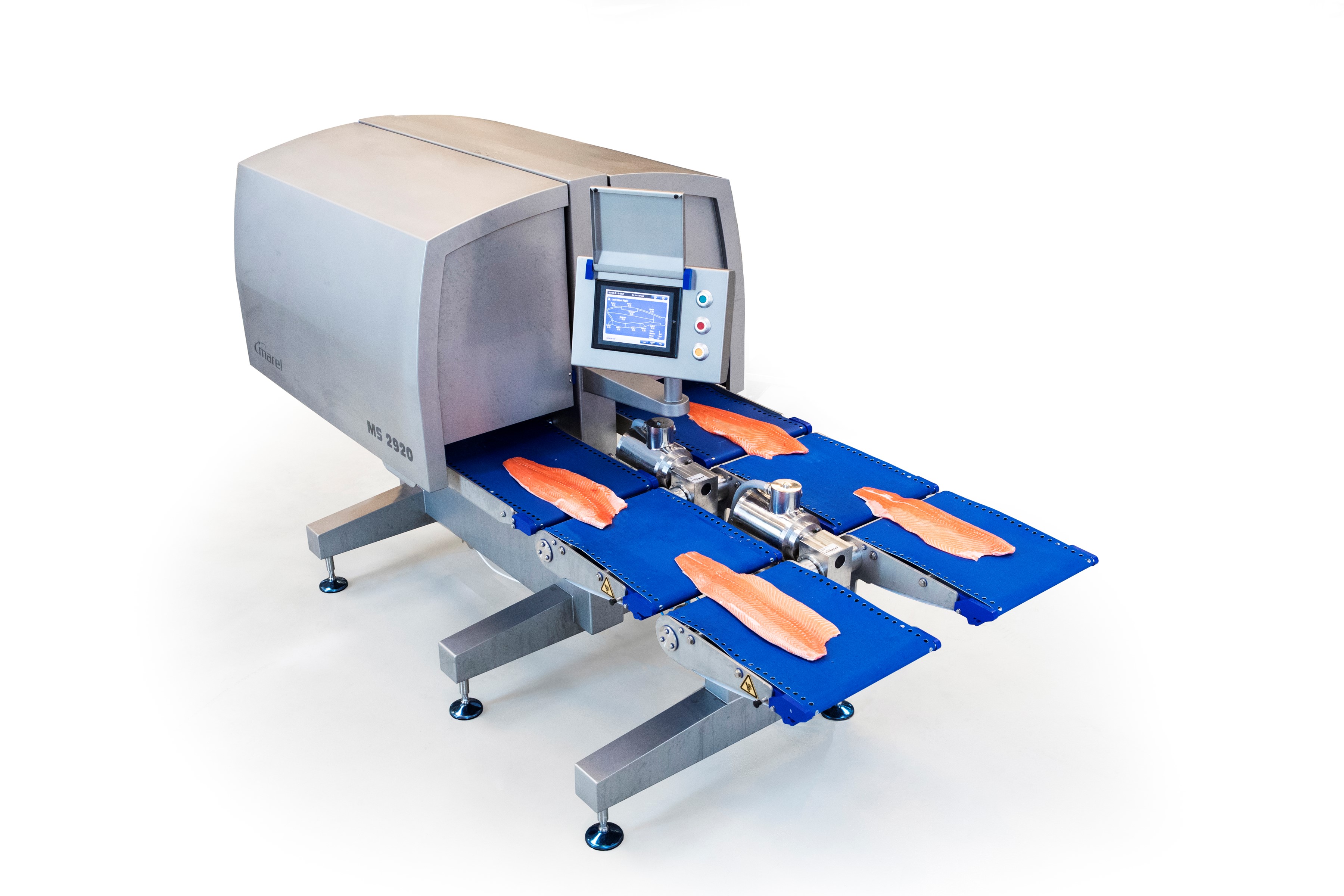

One of the filleting solutions Marel is demonstrating in Copenhagen features the PaceInfeeder – an optimized infeed system designed for the automatic fixed-pace infeed of deheaded fish to the MS 2730 Filleting Machine, resulting in higher filleting quality and reduced labor costs.

The PaceInfeeder is a valuable addition to Marel’s industry-leading filleting solutions that deliver superior filleting with optimum yield. The MS 2730 Filleting Machine also offers automatic back and belly trim, to reduce the need for manual trimming, and automatically adjusts to various fish sizes.