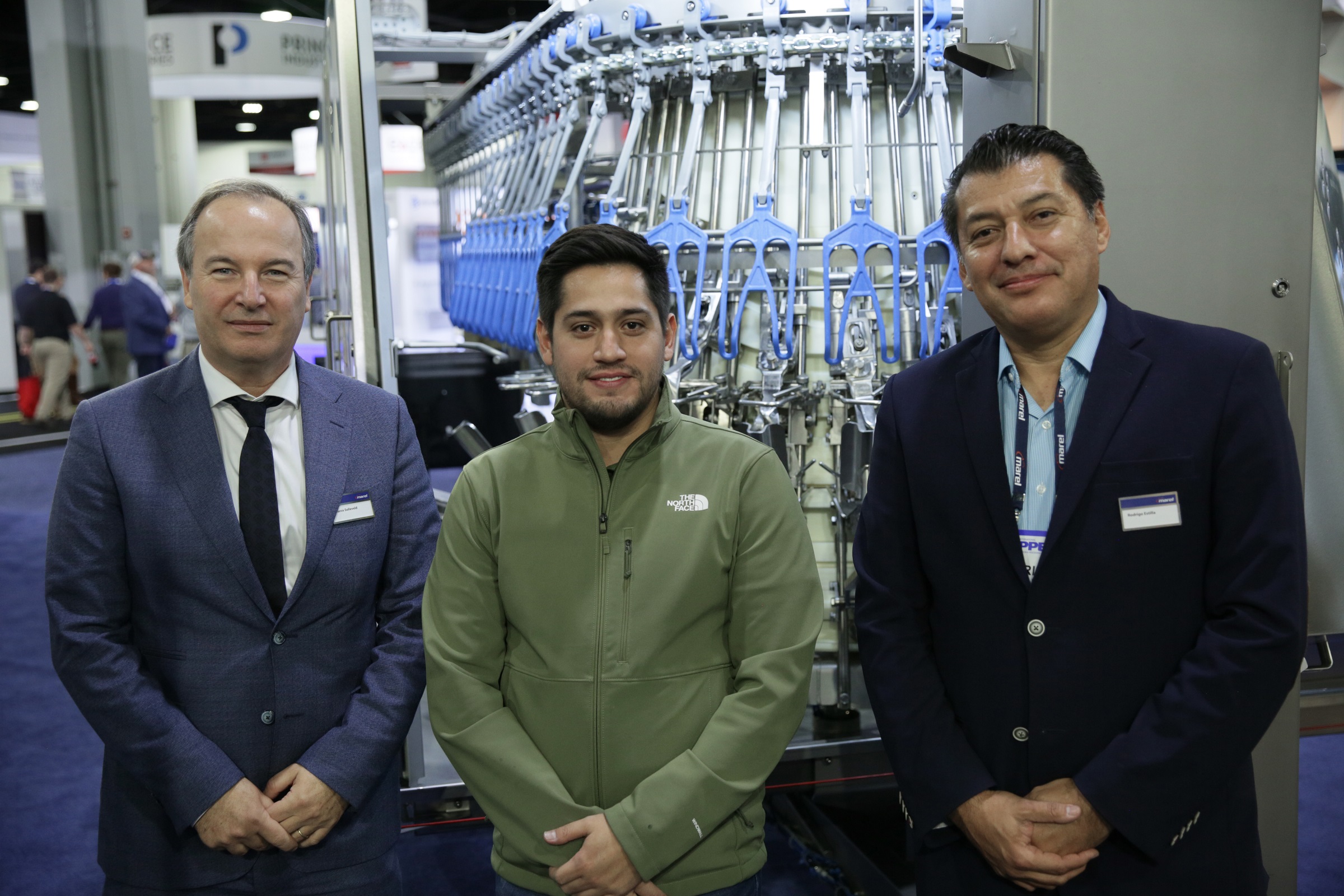

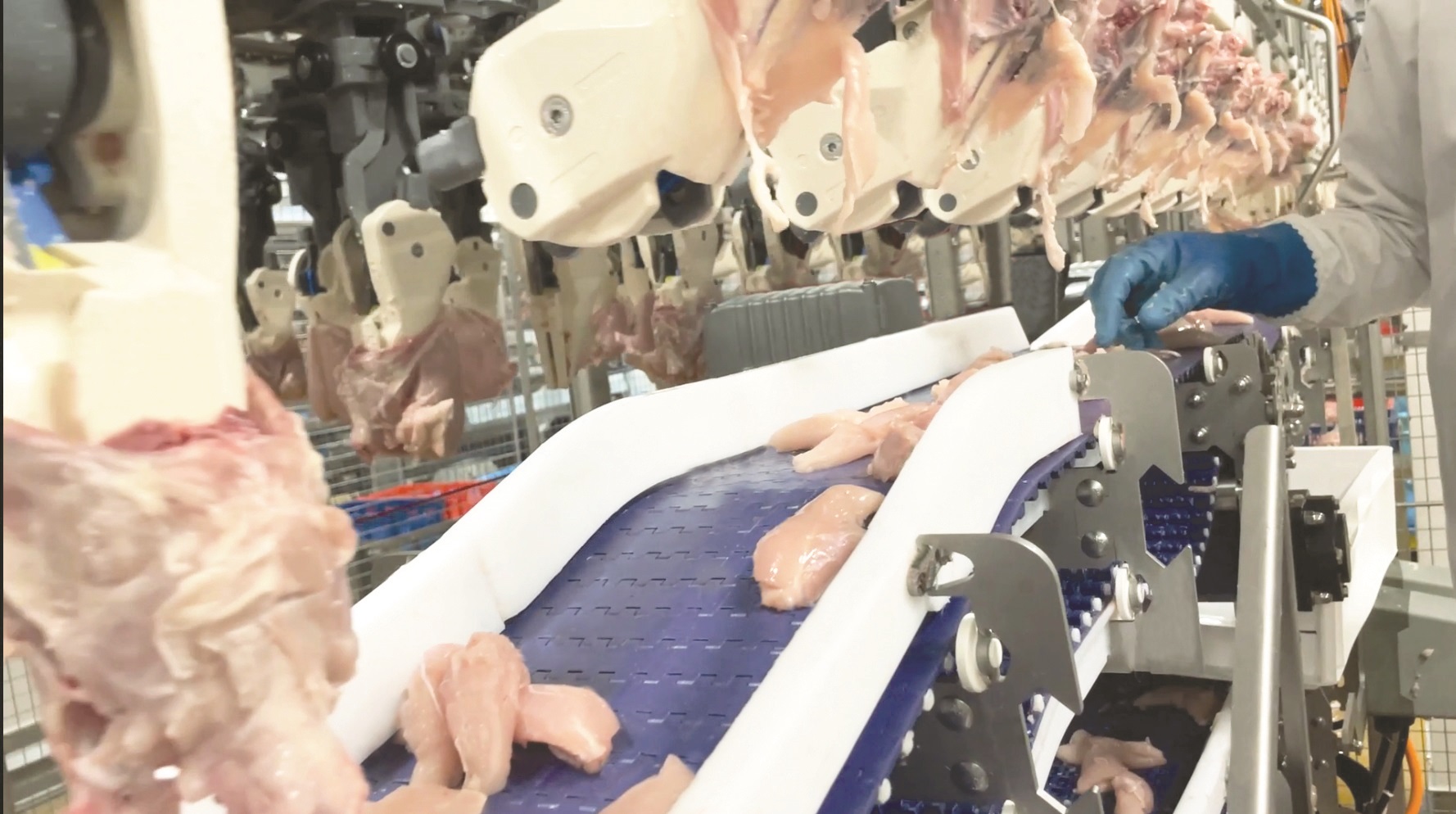

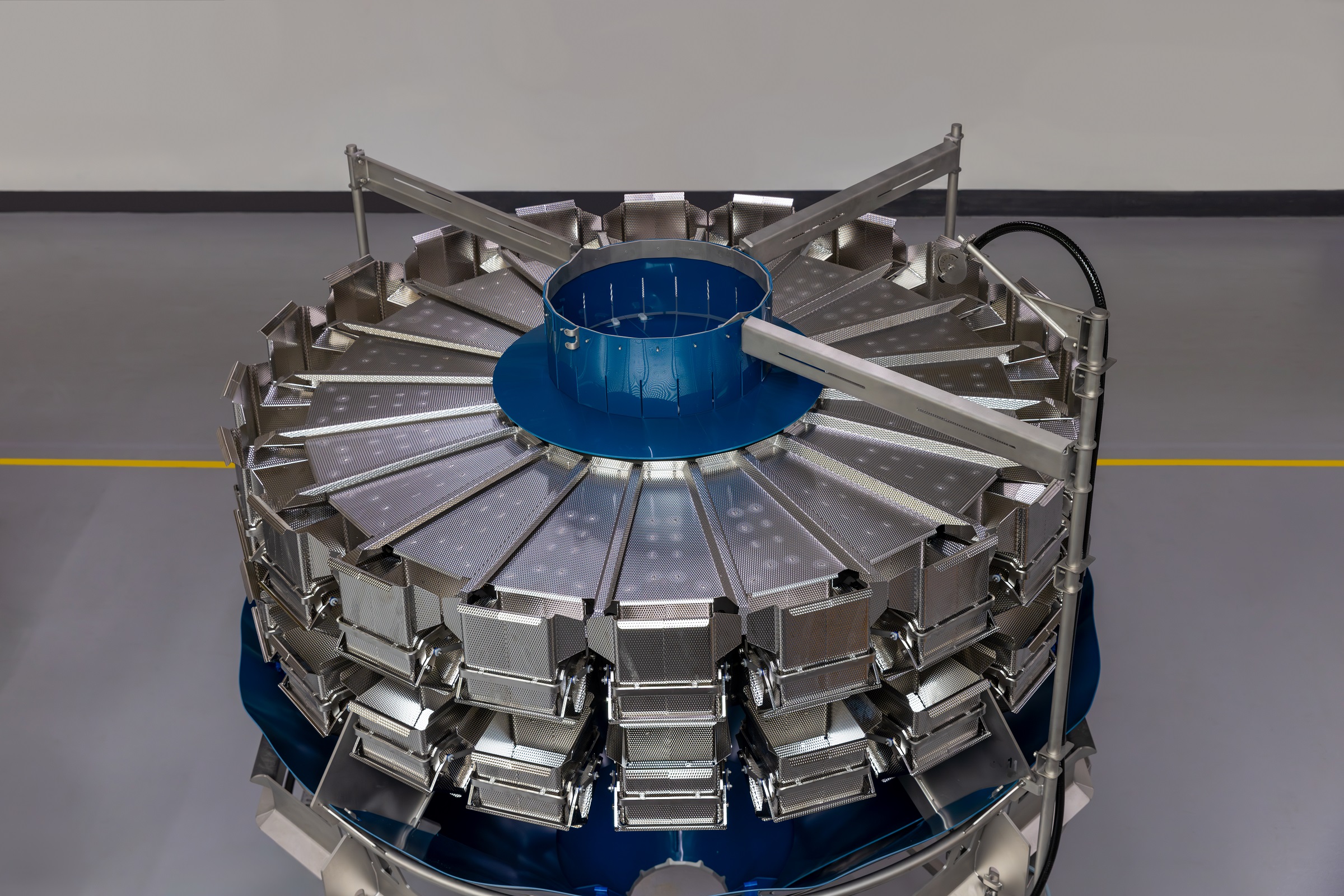

To support our customers with the optimum service solutions, we focus on tailoring service partnerships to our customers’ specific requirements. Each service solution is designed as a partnership between our local service specialists and customers, to ensure it addresses specific needs.

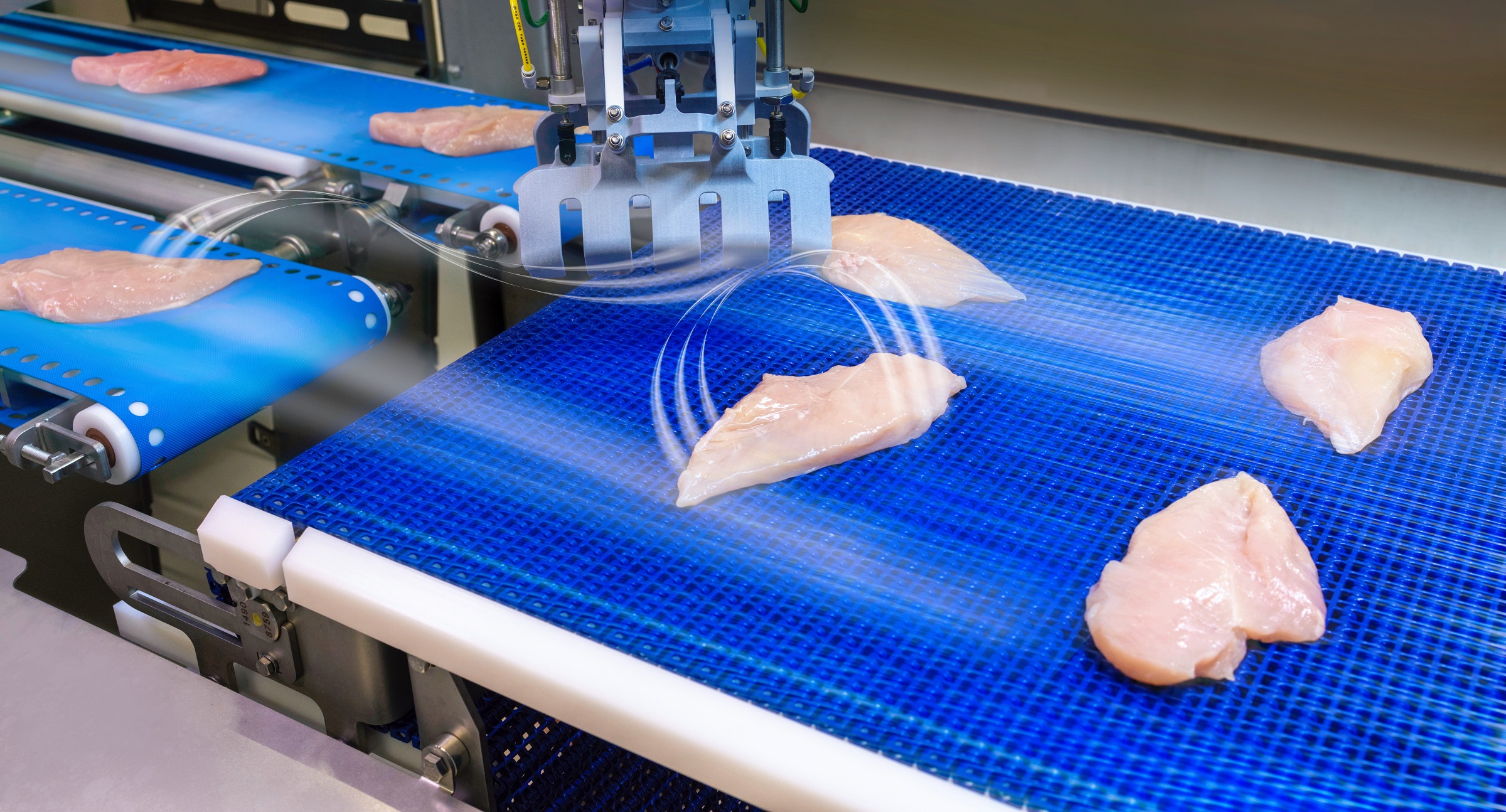

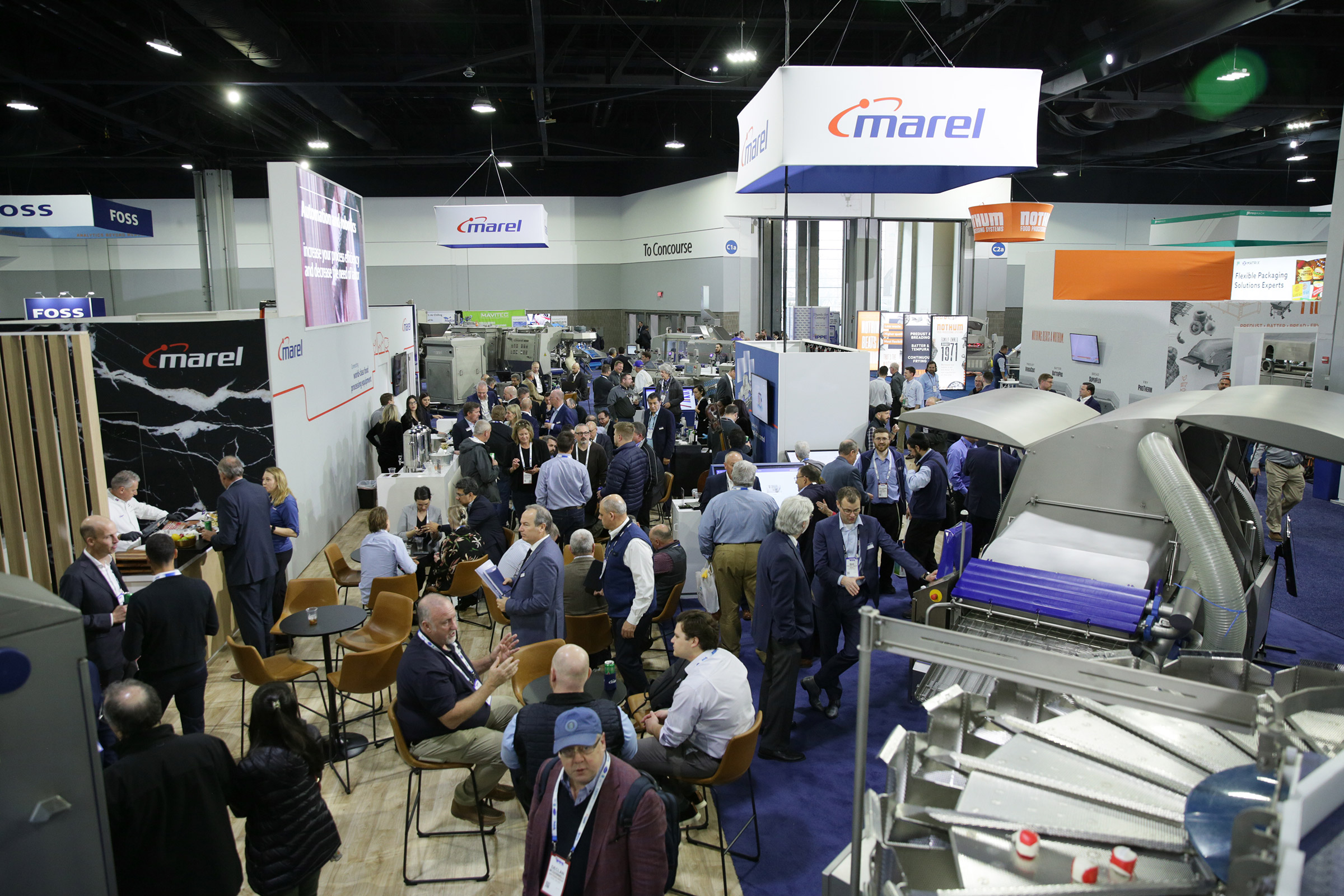

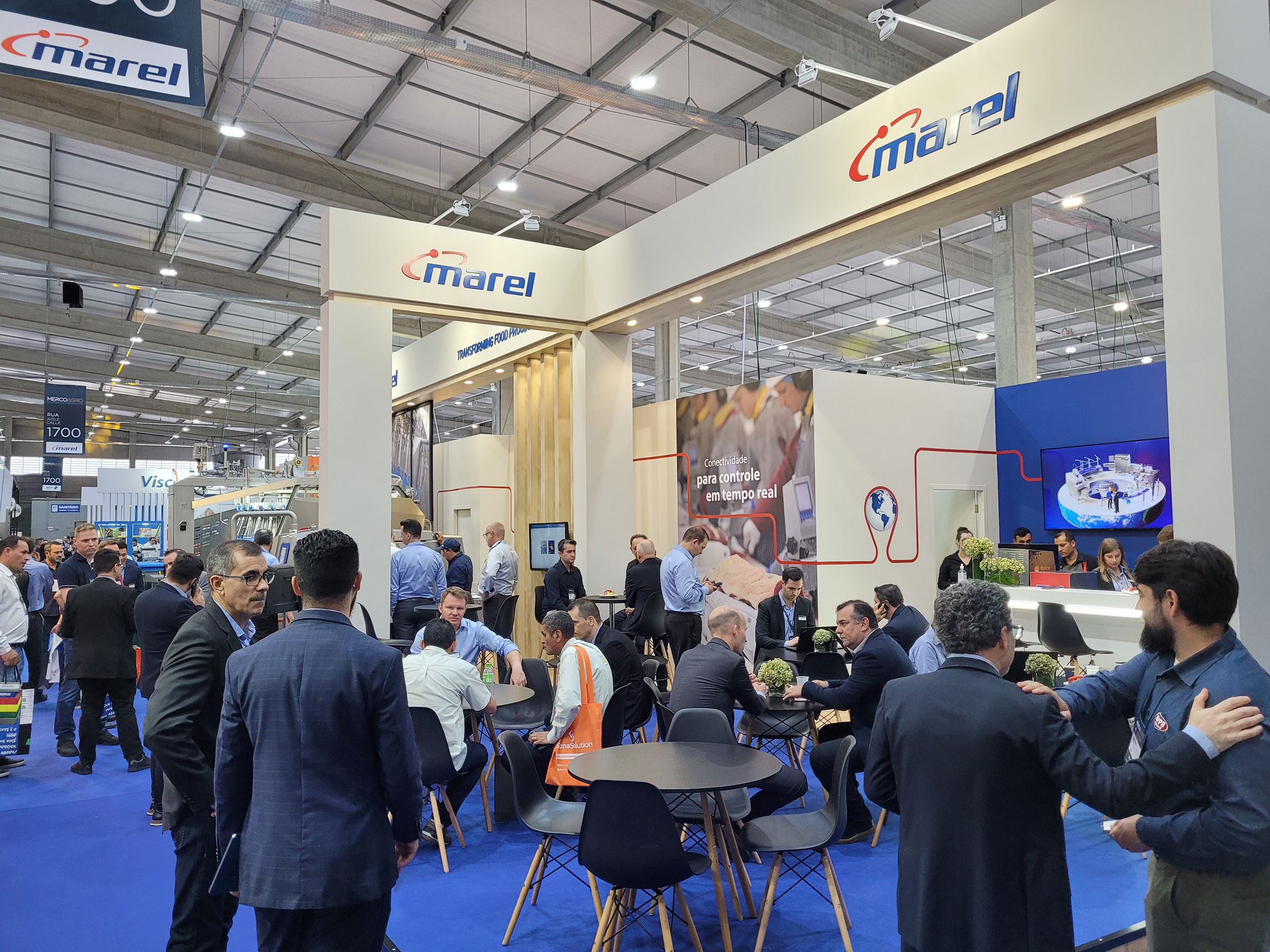

At Marel, we envision a world where food is produced safely, sustainably and affordably. These goals are only achievable through close collaboration with our customers and partners around the world.

Our extensive global sales and service network spans 30 countries and six continents, so expert help is close at hand wherever you are. We believe in global knowledge and local solutions.