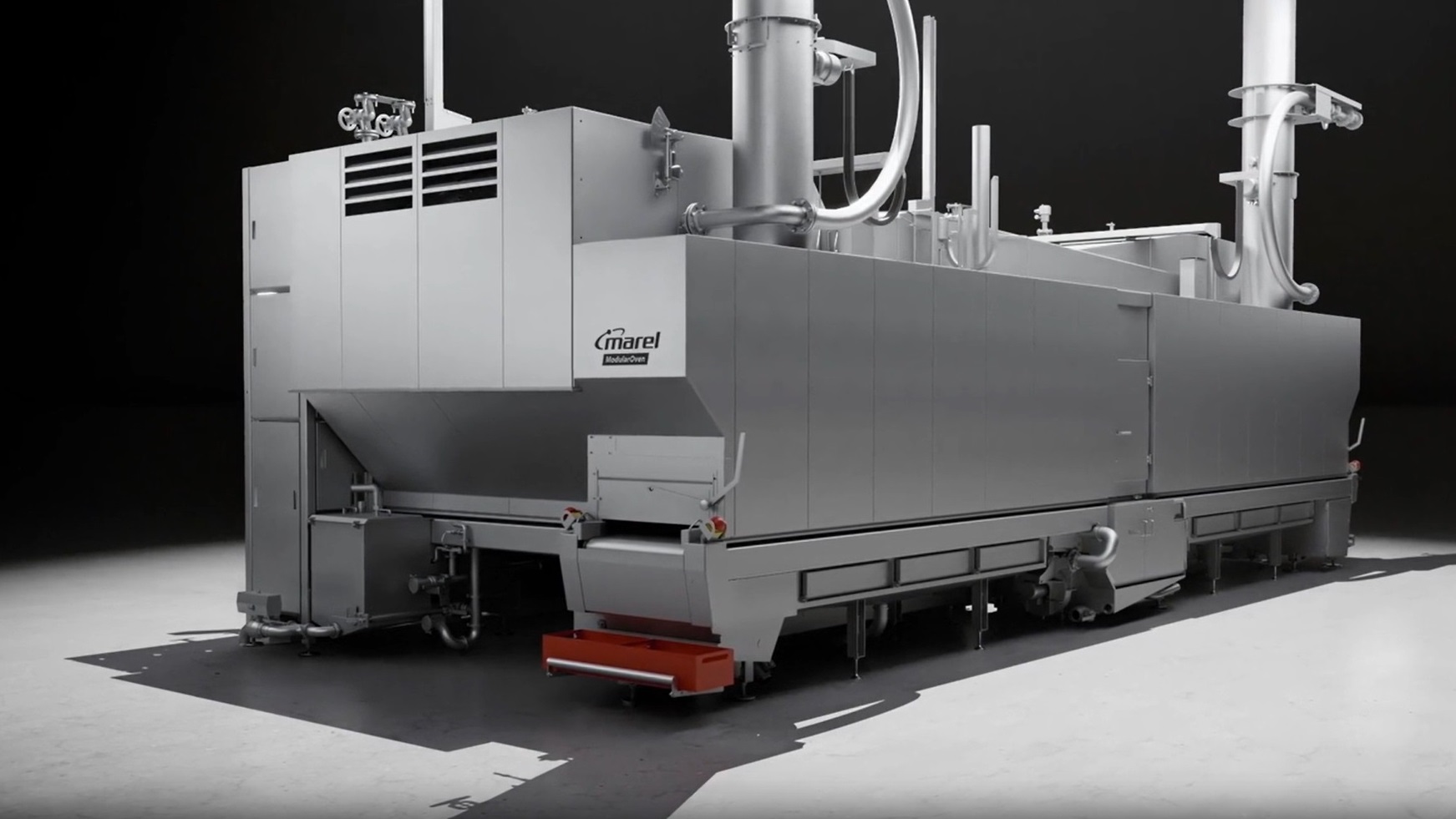

Maximum yield and unbeatable uniformity are the key words for the ModularOven+.

The ModularOven+ offers Marel’s price-winning oven technology which can be customized to your precise production needs. It allows you to start with the features you need to meet your current criteria, with no unnecessary extras. You can tailor the oven to your requirements now and in the future. If your requirements change over time, you add more features and more capacity. You can change, for example, from 500 kW to 900 kW heaters.

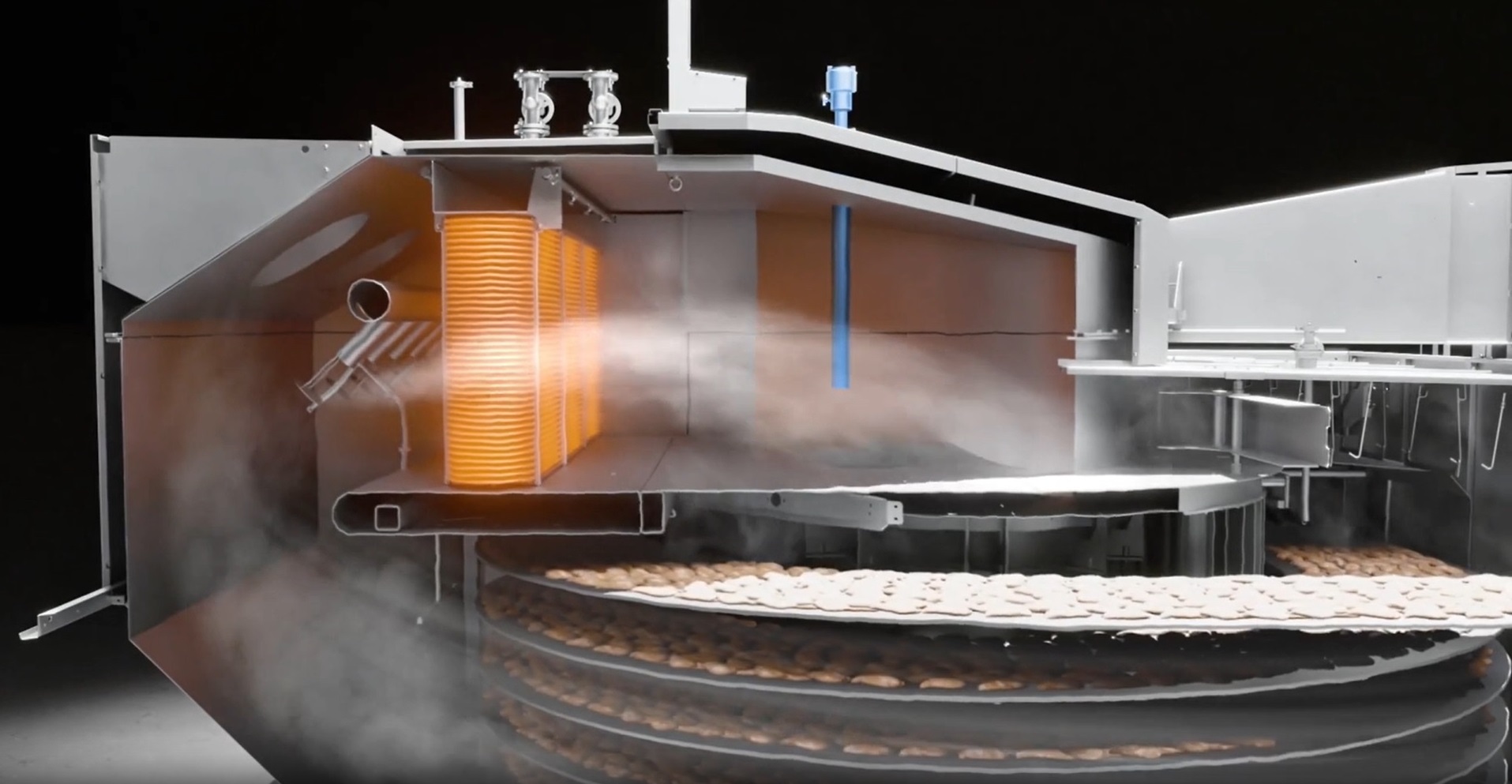

It cooks, steams and roasts

Maximum yield and unbeatable uniformity are the keywords for the ModularOven+ when it comes to creating the highest rate of reproducible quality of products. Drawing on more than three decades of expertise in heating technology, Marel has developed the ModularOven+ to deliver unparalleled levels of flexibility and control over the production process.