We saw the ROI (return on investment) very quickly after installing SensorX.

Vladimir Zagorovskiy

Director General of the factory

The high-tech Polar Sea+ processing facility in Murmansk has a production capacity of 12,000 tons of wild fish per year, including around 5000 tons of premium quality fillets. The primary raw material is cod, but also a large volume of haddock plus other species including catfish, red fish, halibut and plaice – all sourced from the Barents Sea and the Atlantic Ocean.

Polar Sea is part of Norebo, Russia’s largest fishing holding, and the fish is brought to shore by Norebo’s own Murmansk Trawl Fleet, landed at their own pier just 200 meters from the facility.

This location is intentional: The factory was built as close to the source as possible, in order to maintain the freshness and quality of the fish in an efficient, sustainable way.

As Vladimir Zagorovskiy, Director General of the factory, explains, this has the added bonus of giving people the opportunity to live and work in one of Russia’s most beautiful areas, just a stone’s throw from the country’s far north-western coast.

“People coming to the region to work here tend to fall in love with the natural surroundings, the fresh Arctic air, the sea,” he says.

The factory employs around 250 people. “It feels like we’re one big family here. When somebody is new, we always say, “Welcome to the family!” Morale is high and staff turnover is low because people care about the factory and are proud of their work. They care about the fish and the quality.”

Zagorovskiy himself has a long history in the fish industry – going back to his seafaring youth aboard a trawler – and more than 20 years with Norebo, previously under the name ‘Ocean Trawlers’.

“I know fish! I know a lot about fishing, especially cod,” he says. “To be honest, I love my work. I didn’t stop work with the fleet until the day before I started here as general manager just over five years ago [2014].”

It was in 2014 that Vitaly Orlov bought the factory and began reinventing the facility as a pinnacle of modern fish processing technology. When the new 55,000m2 Polar Sea+ factory opened in 2016, it became the largest and most advanced fish processing complex in the region.

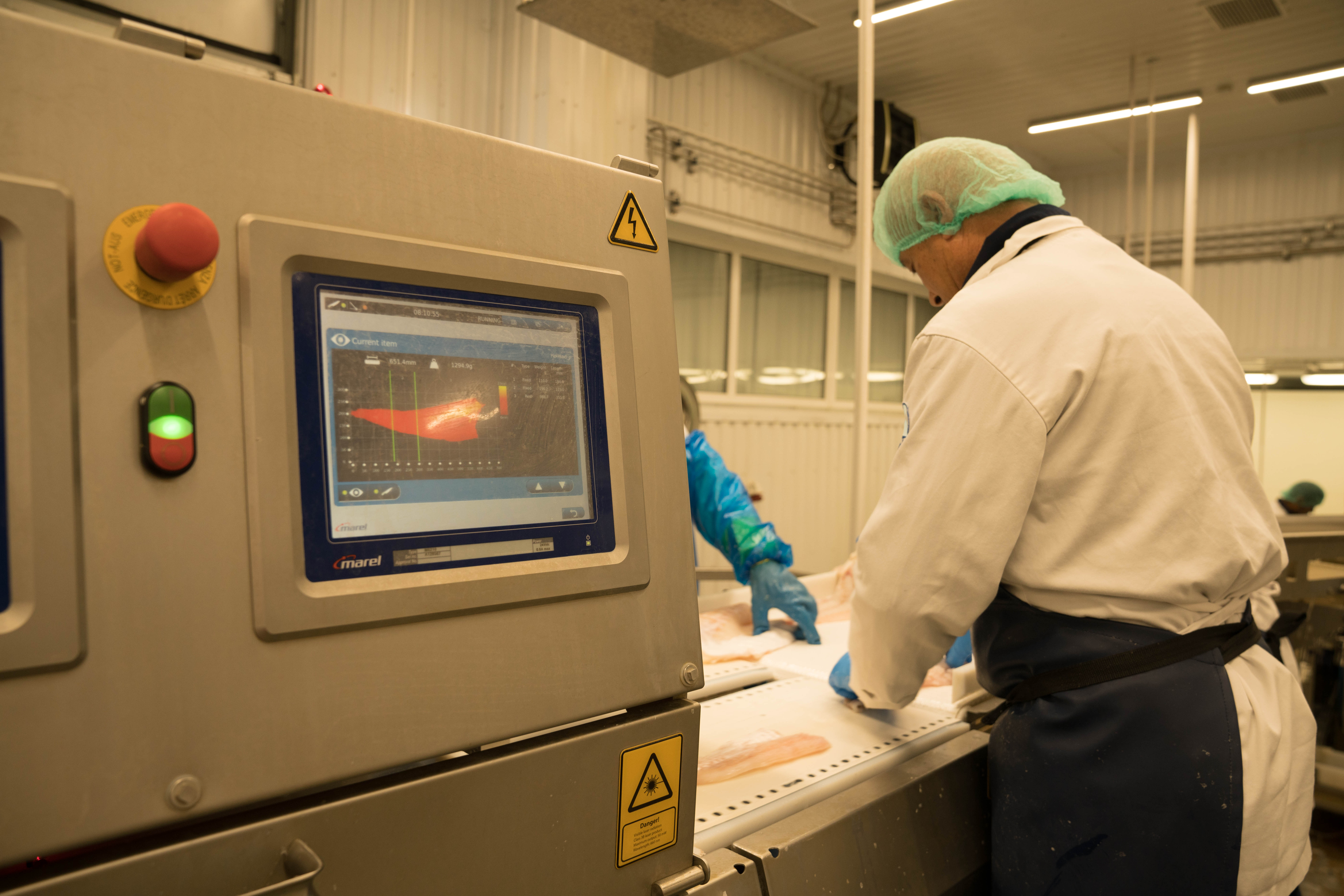

Marel was on board from day one, as part of a project also involving Icelandic and Norwegian providers Skaginn 3X and Optimar. Marel portion cutting and software solutions were in the original drawings, with SensorX, FleXicut and FleXitrim among the more recent additions.

The company’s key output is IQF; individual quick frozen (skin on/off) fillets, and portions, and the off-cuts never go to waste. From the heads to the spines, all by-products are processed. As Zagorovskiy explains, “Our factory follows the principle of processing 100% of every catch: If we receive 1,000 tons, we sell 1,000 tons.”

This is consistent with the company’s very strong commitment to sustainable marine management. Talking about the factory at the official opening in 2016, the head of the Federal Agency for Fisheries, Ilya Shestakov, underlined the importance of using marine bio resources effectively “by means of increasing the depth of processing of extracted raw materials, using wasteless technologies and involving secondary resources in economic circulation. It will help increase the output of products from each ton of caught fish.”

The company’s main market is the UK, but includes other European countries as well as the domestic market. “We’ve started expanding in Scandinavia too. This is a little unusual, with competitors in the Barents Sea and Norwegian Sea, but the high quality of our products has opened that market to us.”

“Our main target is always quality – the owner never presses for higher volumes.” Quality fish, quality equipment and quality people. “We have very strong goals for quality!”

Polar Sea is proud of the feedback it gets from its buyers when it comes to quality. Zagorovskiy says, “We have always achieved high quality results, and our customers seem even happier with our quality since we installed the new Marel equipment.”

“We installed the SensorX in 2018 and the FleXicut system in 2019,” says Zagorovskiy. When it came to investing in SensorX, the decision was easy – the numbers simply added up to a smart business decision.

"We wanted to be sure our products would be boneless – and without any claims. SensorX gives us additional leverage with our buyers because they know that with this equipment from Marel, we can guarantee the maximum number of bones per kilo."

We saw the ROI (return on investment) very quickly after installing SensorX.

Vladimir Zagorovskiy

Director General of the factory

Installing the SensorX was very straightforward, including staff training. “Our technicians were quick to learn how to make adjustments and perform basic maintenance.”

The only issue was how enthusiastic staff were to see the new machine: “For the first week, it was like magic!” Zagorovskiy explains. “We had to remind everyone to keep working instead of watching to see how the SensorX was finding bones!”

The company then invested in FleXicut too, after seeing a demonstration of the machine at the annual seafood expo in Brussels in 2018.

“We saw the FleXicut as a way to speed up production, which is especially important during summer, when the vessels are bringing in a lot of fish very quickly. In July last year we reached record numbers and produced almost 10,000 fillets in just one month, so we want to make sure we can handle those sorts of peaks as efficiently as possible.”

The FleXicut is more complex than the SensorX and it has taken a little longer to get everyone up to speed after installation.

“It’s a bit like the difference between buying a new cup or buying a new sofa – when you bring the sofa in, you’re going to have to rearrange the furniture!”

Zagorovskiy speaks highly of the Marel installation and service teams. “We have great support from Marel, and worked together to modify the factory set-up in order to keep everything flowing.”

The technicians at Polar Sea now take care of all routine adjustments and maintenance. “It’s a question of experience,” Zagorovskiy says, “and our staff are very positive about the equipment. Our trimming operators experience for themselves how FleXitrim is improving performance too.”

Polar Sea are ahead of the field when it comes to traceability and quality control. The factory has been using Innova Food Processing Software from the start and Zagorovskiy sees clear benefits to accessing the Innova data in real time.

“It’s especially important when we’re running several vessels and need to keep track of distribution for traceability purposes, as well as yield,” he says. “It makes it possible to coordinate equipment and lines, and ensures we can access information from any point of a big line.”

When asked whether the factory could possibly run without Marel’s Innova software, Zagorovskiy gives a candid reply: “Of course, it’s possible,” he smiles. “Just as you could drive your car without mechanized gears. But it would be much more difficult!”

The Polar Sea+ factory is unique in Russia, boasting the newest equipment and the latest fish processing technologies.

“Our factory is very modern,” says Zagorovskiy. “With equipment like FleXicut, it seems like a revolution that happened very quickly – [snapping his fingers] just like this.”

The technology will keep advancing, and greater automation will help factories handle greater volumes, but he notes in conclusion that people are still the key operators in the industry.

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.