Information

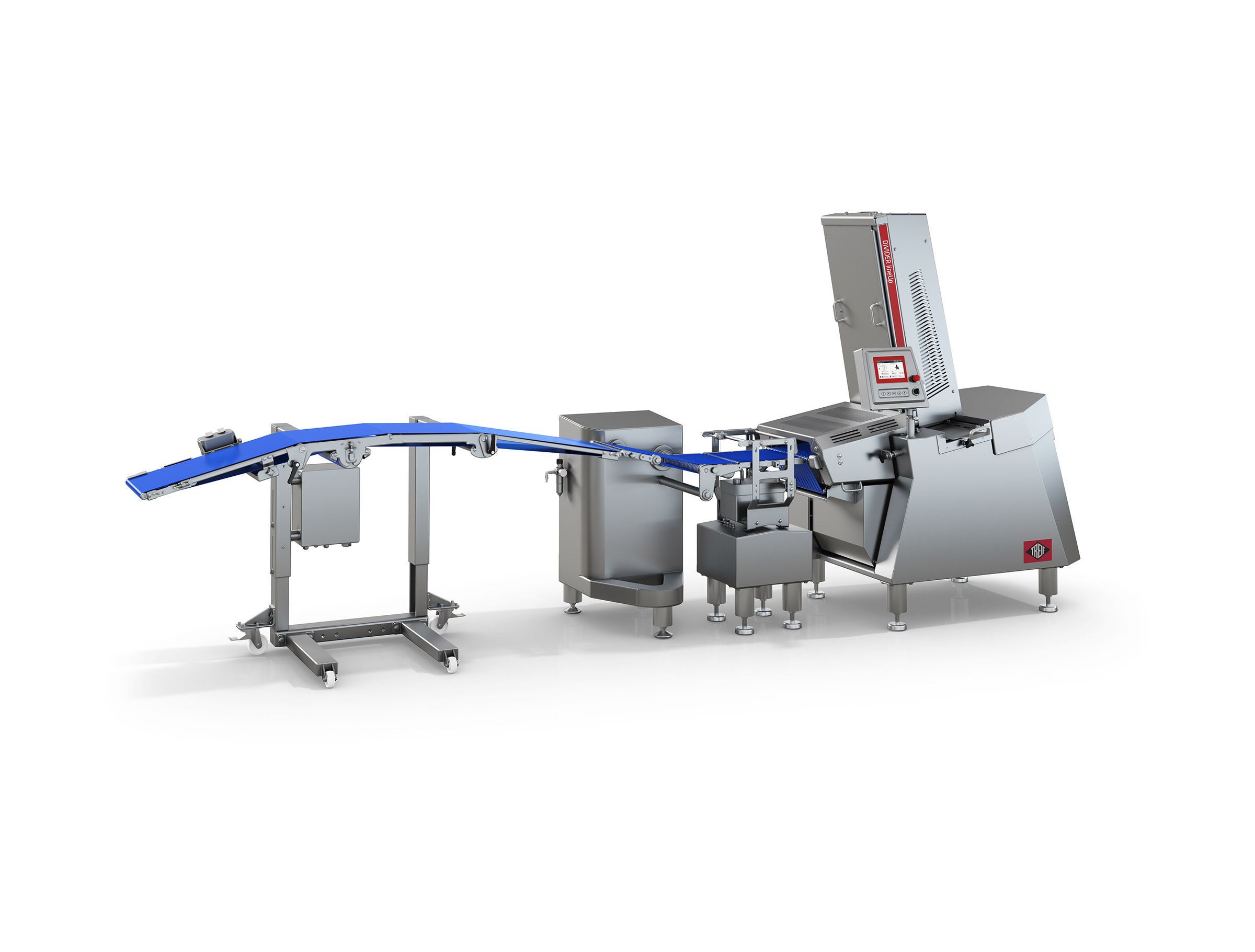

With its small footprint and excellent flexibility, the DIVIDER 660+ is ideal for small to medium-sized processors supplying the cold-cut market.

Create a wide variety of products

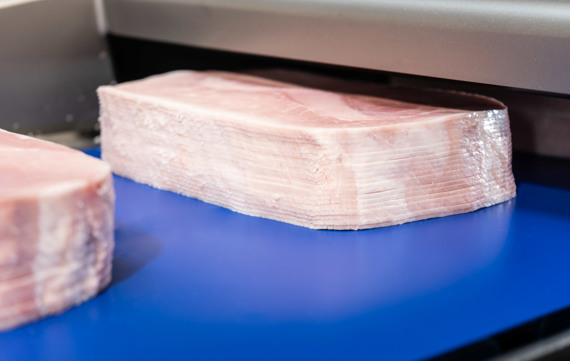

The DIVIDER 660+ can process all protein types and shapes, and stack or shingle in various configurations, such as zig-zag and shaving. The unique tilt of its shaft combined with innovative Marel TREIF blade technology ensures even the most challenging raw materials are always sliced perfectly and presented optimally.

Save floor space - gain flexibility

The DIVIDER 660+ has a smaller footprint than comparable machines. It can operate standalone or easily integrate into a production line. Expansion modules allow production to be scaled quickly and efficiently.

Reduce energy costs

Thanks to unique ECO SLICING technology, the DIVIDER 660+ can slice at higher temperatures. This eliminates the need to cool or crust-freeze raw materials beforehand and gives significant savings on energy costs and production time.

Optimize efficiency

The DIVIDER 660+ can handle multiple units of the same product at once, and slices and stacks simultaneously to give greater efficiency than equivalent machines. It is also intuitive to operate, easy to maintain and designed to meet strict hygiene requirements.