Immediate results

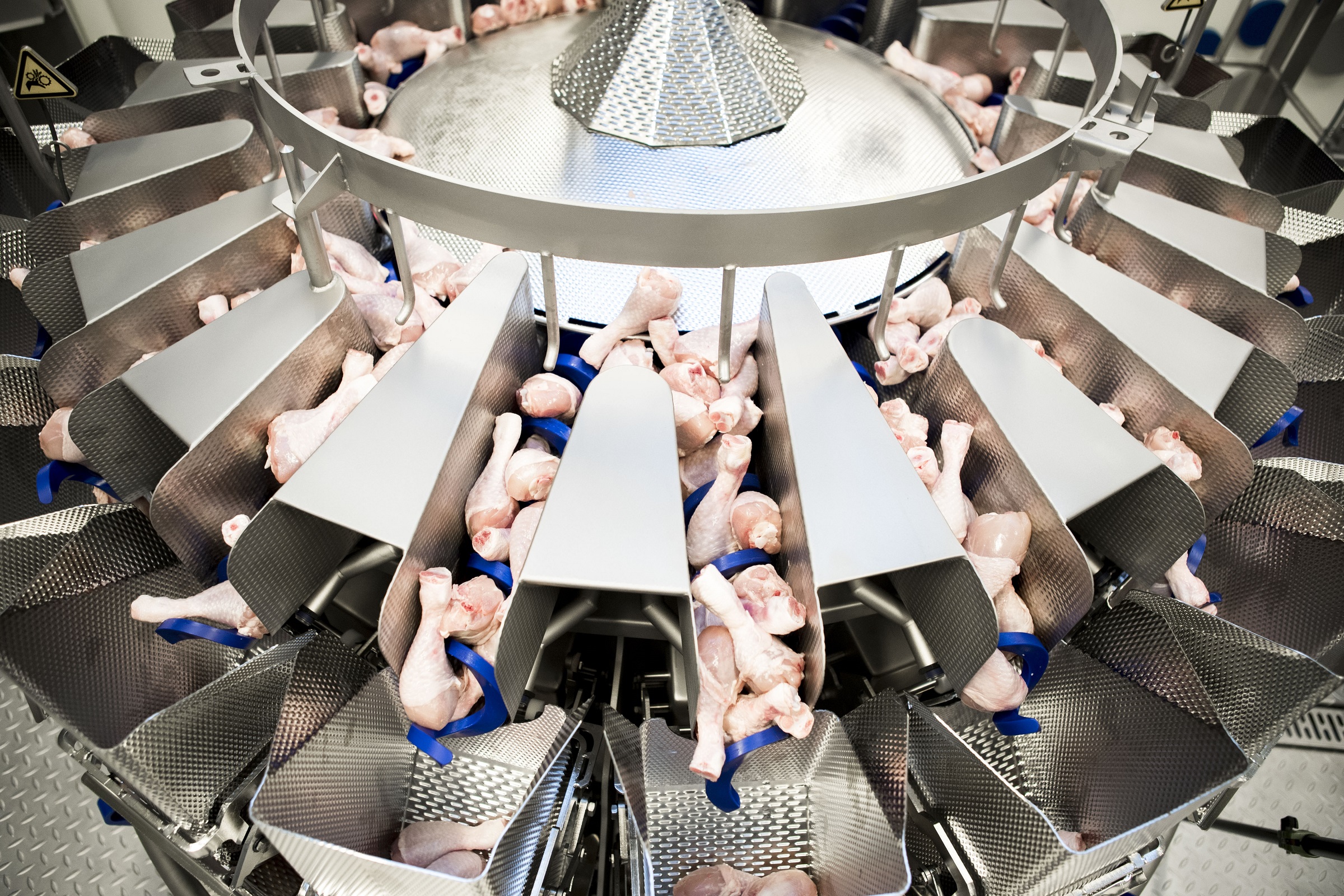

The first Multihead Weigher for bagging wings was installed at the Wallace facility in early 2020. It was an immediate success with both giveaway and labor reduced. “Bag weights were better, the bags looked better, the product looked better all-round,” Cowan comments. The Wallace facility now has seven lines, all with Marel Multihead Weighers, bagging wings, drums, leg quarters, breast meat, bone-in thighs and boneless thighs. Prior to the installs, they were hand-packing all products. Throughout their facilities, House of Raeford has now installed a total of 13 Multihead Weighers!

Successful install

There is a lot of history between House of Raeford and Marel, which has led to a close relationship with solid mutual trust. Marel’s service team, for example, provided great support during the install process. “The experienced team that Marel brought to us made a huge difference in our people learning the right way to do things,” continues Cowan Johnson.