Golden State Seafood has significantly advanced its salmon processing operations by investing in our cutting-edge Filleting Machine MS 2750. We sat down with Art Kavoukjian, CEO and Owner of Golden State Seafood, and Charles Clay, Director of Sales and Operations, to discuss the company’s evolution, their commitment to sustainability, and how Marel’s technology has transformed their processing capabilities.

Golden State Seafood transforms salmon processing efficiency with MS 2750

The LA-based processor delivers high-quality salmon fillets from around the world while conserving water, thanks to the Filleting Machine MS 2750

Implementing the MS 2750 has significantly improved Golden State Seafood’s yield, throughput, and product quality while freeing up valuable time and resources, allowing the company to explore new opportunities and expand its product offerings.

Expanding operations with a commitment to quality and sustainability

Golden State Seafood, founded over 30 years ago, has grown from a modest operation into one of the most impactful salmon processing factories in Los Angeles, California. The company’s mission is to deliver high-quality, sustainably sourced salmon from around the world to meet the demands of both retailers and food service providers. This commitment drives their continual pursuit of excellence and innovation.

Partnering with Marel for state-of-the-art salmon processing solutions

The collaboration between Golden State Seafood and Marel began with the acquisition of a used Marel salmon portion cutter. Over time, this partnership has flourished, leading to the recent investment in the Filleting Machine MS 2750 for salmon.

Charles Clay emphasizes: “We saw an opening to make a difference out here as a salmon processor. Seventeen years later, here we are, making a difference in this business.”

Enhancing efficiency and yield with the MS 2750

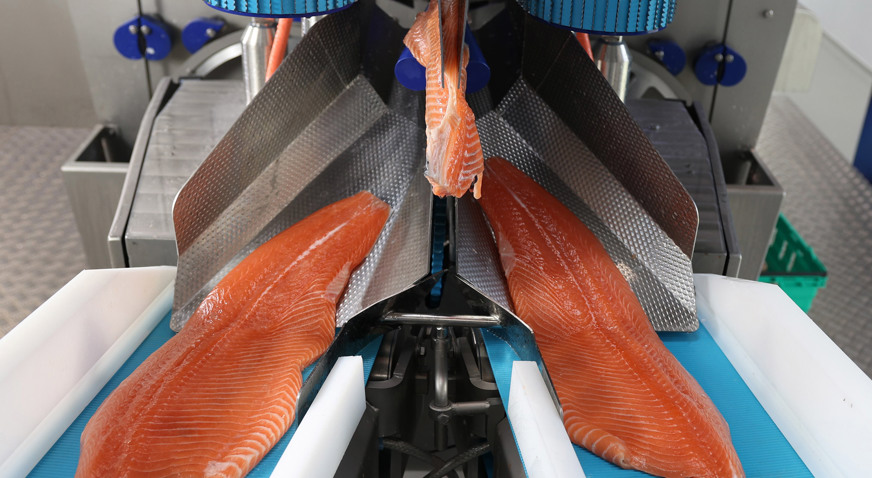

In 2024, Golden State Seafood took a significant leap forward by incorporating the MS 2750 into its salmon production line. The MS 2750, renowned for its extraordinary durability and flexibility, maximizes yield and enhances daily operations. This advanced salmon filleting machine processes up to 25 fish per minute without operator input, drastically reducing labor dependency and improving yield.

Larry Couch, Key Account Manager at Marel, highlights the machine’s capabilities: “The MS 2750 is the latest in Marel salmon filleting processing machinery. It's a fully automated, self-adjusting, servo-driven, computerized salmon filleting machine. Truly a phenomenal piece of engineering. They thought about everything.”

The MS 2750’s modular design not only ensures robust performance but also simplifies maintenance and cleaning, thus minimizing downtime. Additionally, the machine’s efficient water usage—only 15 liters (~4 gallons) per minute—aligns with Golden State Seafood’s commitment to sustainability.

Couch elaborates: “The MS 2750 uses substantially less water than our competition's machines, which is a huge factor in operating costs. Water is expensive all over the world, but particularly here in Los Angeles, where water is in short supply.”

Leveraging SmartBase for enhanced connectivity and efficiency

Marel’s SmartBase, a secure cloud-based digital solution, comes standard with the MS 2750. This platform provides real-time data on machine health and performance, enabling operators to make data-driven decisions that enhance uptime and efficiency. SmartBase’s dashboard allows easy problem resolution before issues arise, reducing the downtime risk.

Clay adds: “The fact that the machine just runs, it just keeps going. The stock doesn’t beat up the fish. It’s very easy to keep the machine up and running.”

Looking ahead: continuous improvement and expansion

Implementing the MS 2750 has significantly improved Golden State Seafood’s yield, throughput, and product quality while freeing up valuable time and resources, allowing the company to explore new opportunities and expand its product offerings. With the ability to process salmon sourced from all around the world, the MS 2750 can handle various types of salmon, including different wild species and farmed varieties, automatically adjusting to ensure perfect filleting every time.

Art Kavoukjian remarks: “We can go from a 16-pound fish to a 4-pound fish, and it fillets both perfectly without us having to adjust a single setting. It's unreal.”

Couch also notes the flexibility of the MS 2750: “This machine really automates the salmon filleting process, which is a very difficult task, not only because manual filleting is physically challenging, but also because of the different types of salmon. There are five wild Salmon species: Sockeye, Chinook, Chum, Pink, and Coho and several farmed Salmon species including Atlantic, Steelhead and Trout. The 2750 addresses all of these within the size range of the machine.”

Kavoukjian concludes: “I think we’re the first ones in North America to get the machine. Our investment in the MS 2750 and our partnership with Marel testify to our commitment to innovation and sustainability. We’re excited about the future and the new possibilities this technology brings.”

Clay adds: “You’ve seen our fillets - nobody can match our fillets. The best has yet to come.”

With Marel’s support, Golden State Seafood is poised for ongoing growth and advancement, ensuring they remain at the forefront of delivering top-quality, sustainably sourced salmon to consumers. This partnership exemplifies how embracing advanced salmon processing solutions can drive success and set new standards in the seafood processing industry.

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.