Jump to:

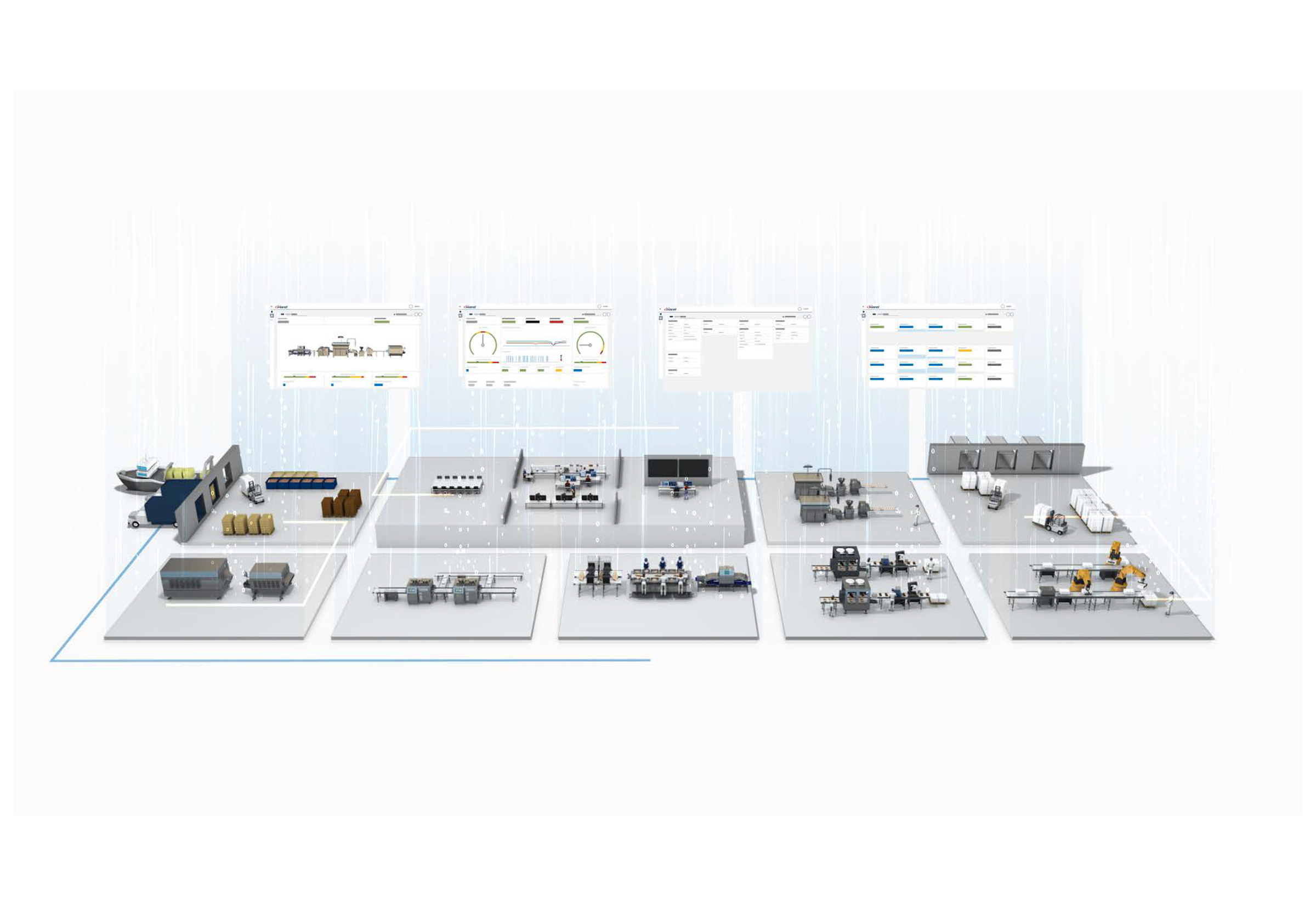

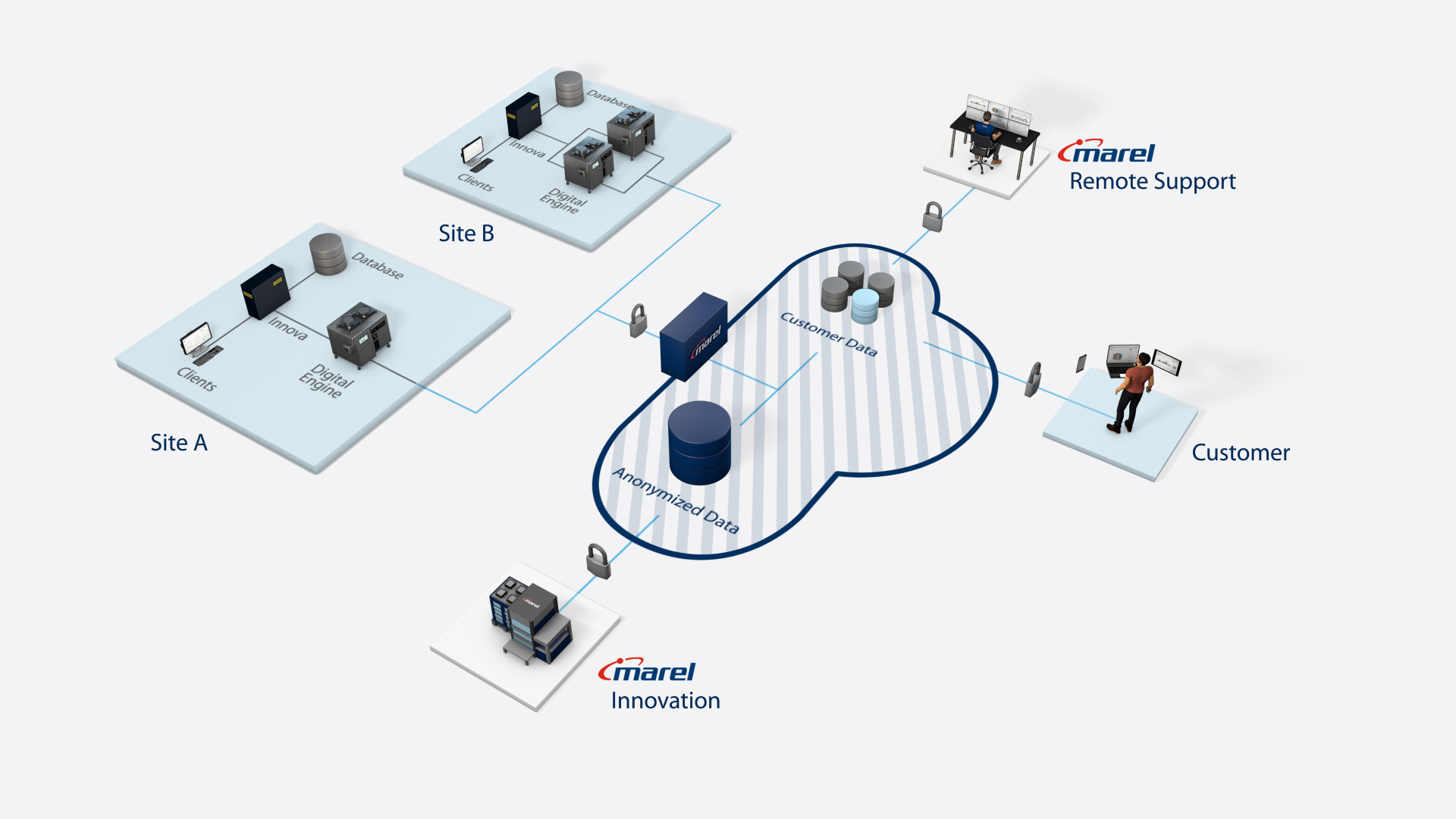

Marel is transforming the industry as it moves toward enhanced software offerings built on a new digital platform. By deploying these digital solutions, food processors will be able to interconnect factory equipment, making it effortless to configure, easy to control, and fully manageable through a cloud-based infrastructure. Today, the cornerstone of the overall Marel Digital undertaking is connectivity: the development of an extensive digital ecosystem for food processing.