Distribuidora Milenium in Colombia

Distribuidora Milenium produces and sells top-quality food products, serving more than 2,500 customers in fast food companies, restaurants, industrial food and hotels in Colombia.

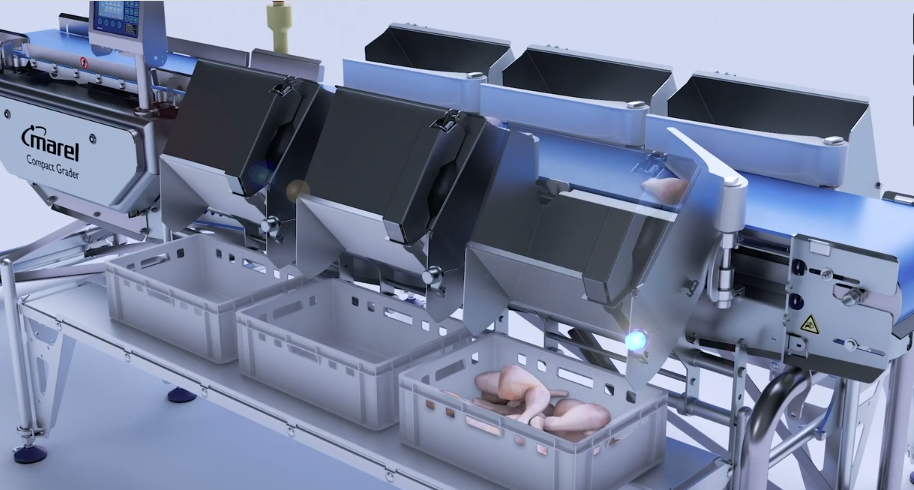

Thanks to the wide range of live bird weights and end products, grading is a critical point in the production process. Andean poultry processors have chosen Marel’s Compact Grader as the most versatile solution for weighing and classifying a wide variety of fresh and frozen poultry products.

The combination with Innova software gives even more support and less room for guesswork. Information on all batches produced is stored. Standard reports can then be created, giving an insight into operational performance on a daily, weekly or monthly basis.

Distribuidora Milenium produces and sells top-quality food products, serving more than 2,500 customers in fast food companies, restaurants, industrial food and hotels in Colombia.

The company bought a Marel Compact Grader about a year and a half ago. Visiting Marel’s stand during IPPE, the company learned about the equipment and how it could be applied to the fresh chicken fillet grading process. The company processes chicken fillets from 90 to 250 grams [3 - 8.8 oz] and uses the Compact Grader to generate greater productivity in the grading and batching process, ensuring products of exactly the weight demanded by food service and supermarket customers.

General Manager Fernando Gomez Ramirez says, “We work with the Compact Grader all the time, processing between 8 to 10 tons of product daily over 16 hours. The system helps us a lot in our production line, because it is extremely accurate. It allows us to optimize fillets and consequently reduce trimming and giveaway. Apart from reducing the number of people and giving weight away in the grading process, injuries caused by repetitive manual work are down too. The Compact Grader is perfect for most processes in our plant. It is also a very robust and efficient machine with very low maintenance costs.”

Sofía Ltda has established itself as a reference company in the Bolivian food industry. Its team of more than 2500 employees is highly trained in all production and control processes. The company focuses on continuous improvement, ensuring the quality and safety of its products throughout its portfolio.

Three Compact Graders are located at different production stages. The first one, installed after the chiller, classifies large and small B-grade whole chickens. The most uniform products are selected for the cut-up line. The other two Compact Graders grade final products such as wings (different sizes are needed to meet customers’ requirements) and whole chickens. For customers who demand particular accuracy, items are weighed a second time. 85% of products for the national market are whole chicken, 15% are cuts. Sofía Ltda operates a two-shift regime of about 15 hours in total. The equipment is in constant use without major issues or unscheduled stops. With three Compact Graders working continuously and having acquired three new ones, Sofía Ltda has decided to add Innova software to monitor and store production data.

Miguel Ángel Cirbian Peña, Manager Finished Products, says, “We use the graders to be more precise in weighing the final products. Apart from weighing in-line, the graders give us more accurate final product weights. We use the Compact Graders to divide whole products into weight ranges and choose the best destination for them, cut-up or whole griller. We use our new Compact Graders to weigh small products such as wings, whole legs, thighs, breast fillets and more. We are delighted with the accuracy of the equipment. The machines don’t need a lot of maintenance and their compact design doesn’t take up much space. The control panel is very user-friendly. Everybody can operate and program it."

Apart from weighing in-line, the Compact Graders give us more accurate final product weights.

Miguel Ángel Cirbian Peña

Manager Finished Products Sofía Ltda

‘Pollo a la Brasa’ is considered to be the national dish of Peru. Don Pollo recently started to produce and supply this muchappreciated rotisserie chicken to the local market. Today, the product represents 20% of Don Pollo’s total production of poultry products.

The rotisserie chickens typically weigh between 1.5 and 1.9 kilos [3.3-4.1 lb]. To ensure that these products are delivered in accordance with the weight specifications required by Don Pollo’s customers, the company installed a Marel Compact Grader right after evisceration.

Production Manager Josef Guevara Ramírez says, “Our customers ask for products in specific weight ranges to be converted into units in their restaurants.

Offering them products with a weight outside the permitted tolerance would mean a cost increase of each piece of meat for our customers. Therefore, our products must be of a consistent size. Here Compact Grader has helped us enormously.”

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.