The challenges of processing layers

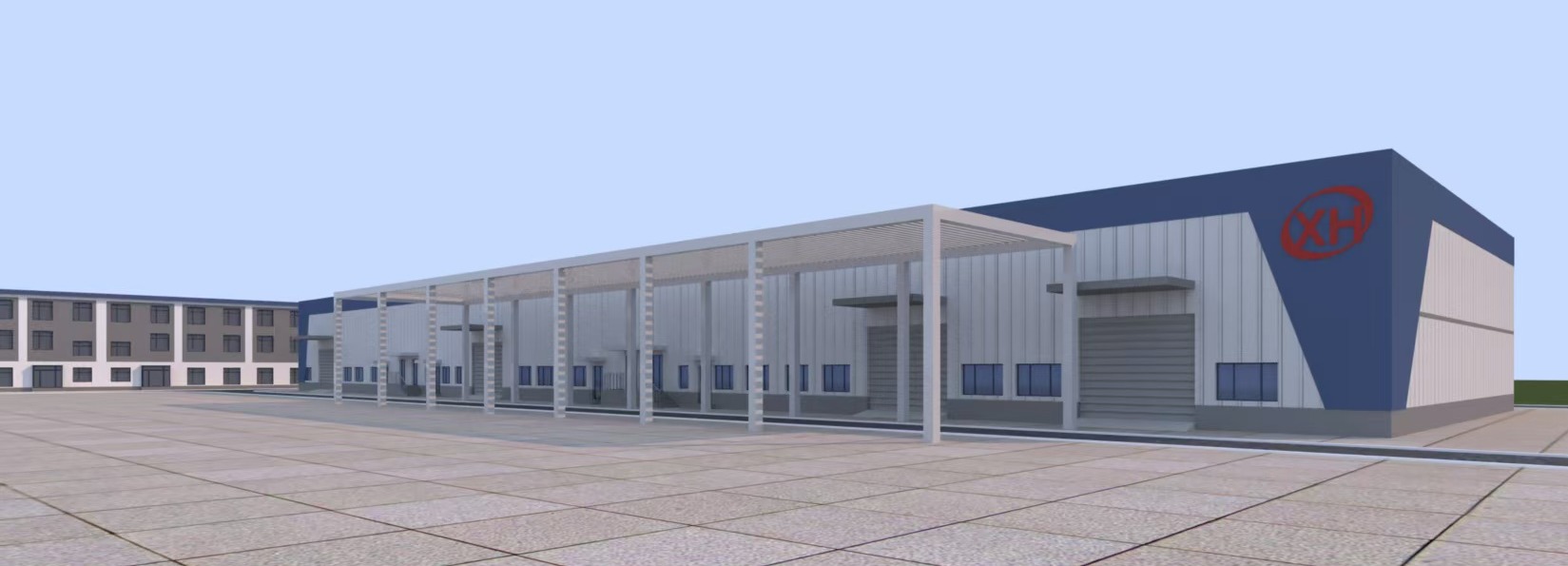

Processing layers is very different from processing broilers. Layers are older birds with thinner legs, tougher carcasses, and fully developed intestines. Their reproductive systems may also contain unlaid eggs during processing. Managing these challenges in-line requires precise control and careful adaptation of the equipment. With JBT Marel’s support in automating the process, Xinhui is confident to handle layers effectively.

Eva van der Velde, JBT Marel’s process technology expert, will personally oversee the on-site commissioning. She explains: “Processing layers calls for special attention and a customized approach. Due to their stronger build and different shape compared to broilers, great care must be taken—not only to avoid damaging the equipment, but also to protect the products from incorrect infeed or outfeed handling. Another challenge is speed—processing 12,500 layers per hour has never been achieved before. And finally, local Chinese preferences regarding the appearance of the end product must be taken into account. That’s why maintaining close contact with Xinhui is essential to fully understand and meet the exact requirements.”