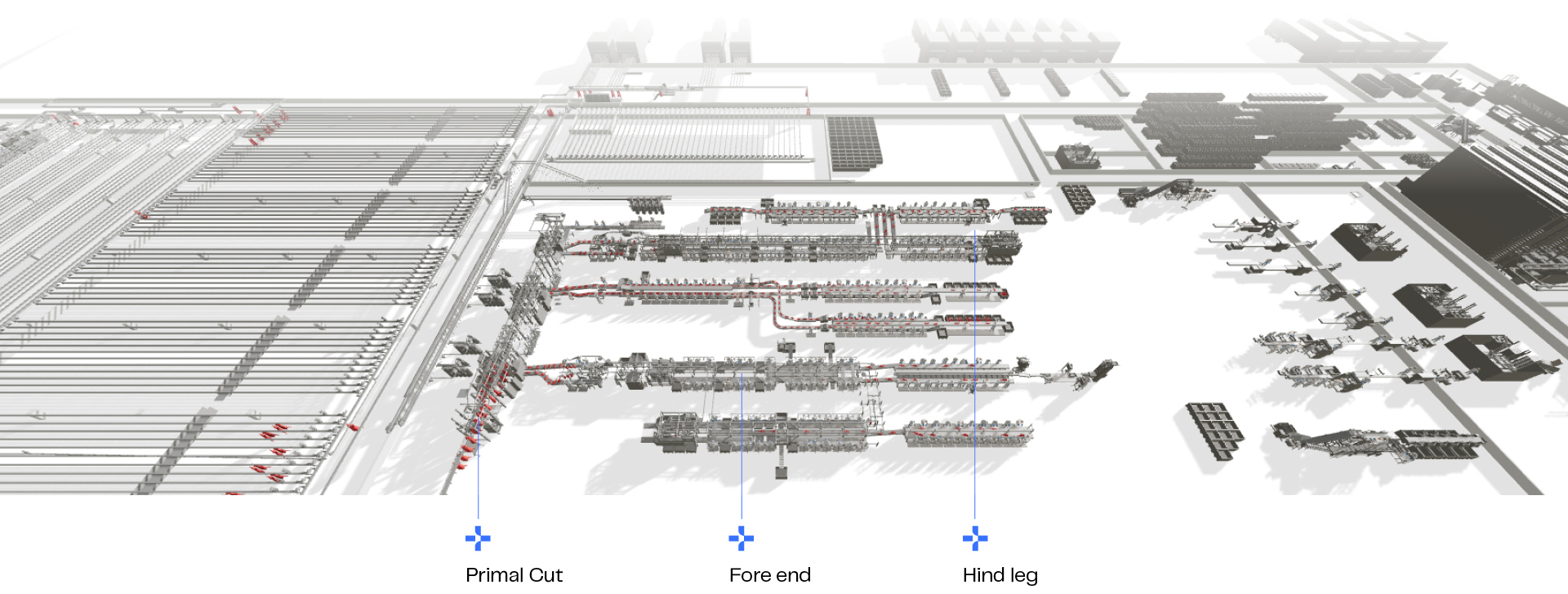

Seeing the DeboFlex system in direct combination with the StreamLine made us realize that there is a possibility for ‘really doing it right’.

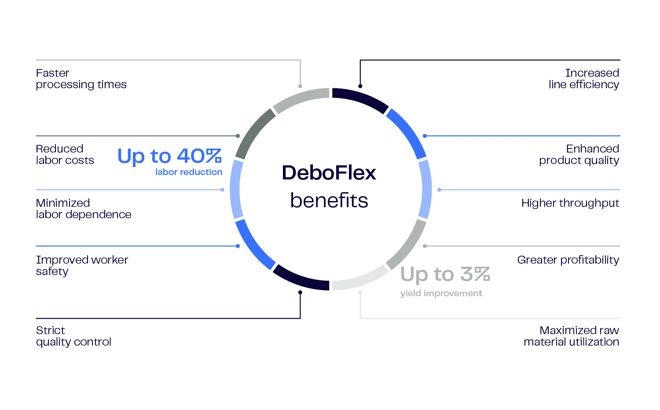

Pork processors face increasing pressure from rising labor costs, limited availability of skilled workers, and the need for consistent, high-quality products. Conventional table-top or pace-line deboning makes it difficult to maintain yield, ergonomics, and process stability at scale.

The DeboFlex offers a new approach: a modular, vertical deboning platform that provides structure, control, and efficiency. Each primal is suspended and securely positioned, creating a stable and continuous flow. By combining secure positioning, vertical orientation, and ergonomic workstations, DeboFlex reduces manual handling, increases knife-in-meat time, avoids product repositioning, and supports higher yield, improved safety, and scalable automation across pork secondary processing.