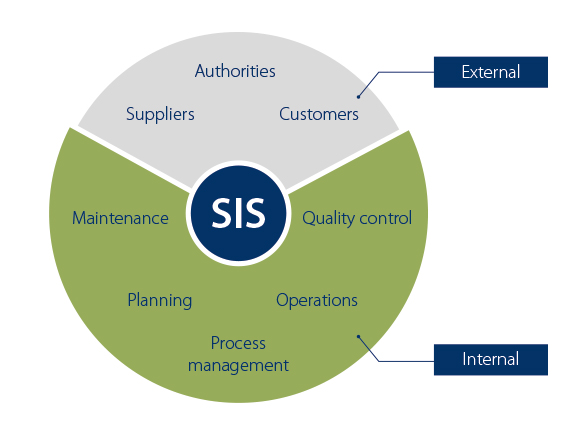

Give your people the advantage

Deploy primary processing software to capture and communicate data that can verify processing steps in real time and inform everybody’s role on the factory floor

Leadership and workers at all levels of your organization can use software to improve production by coordinating the primary process and logistics stages. Learn how each role can benefit from with hands-on data visualizations and analytics.

Plant Manager and CEO

The Plant Manager and CEO are focused on the operation’s supply chain, and put a value on whether products meet standards, move efficiently through the facility, and fulfill orders in a satisfactory way. Leadership gains oversight into whether products are processed and shipped in a timely way that supports the most advantageous cash flow situation.

Production Manager

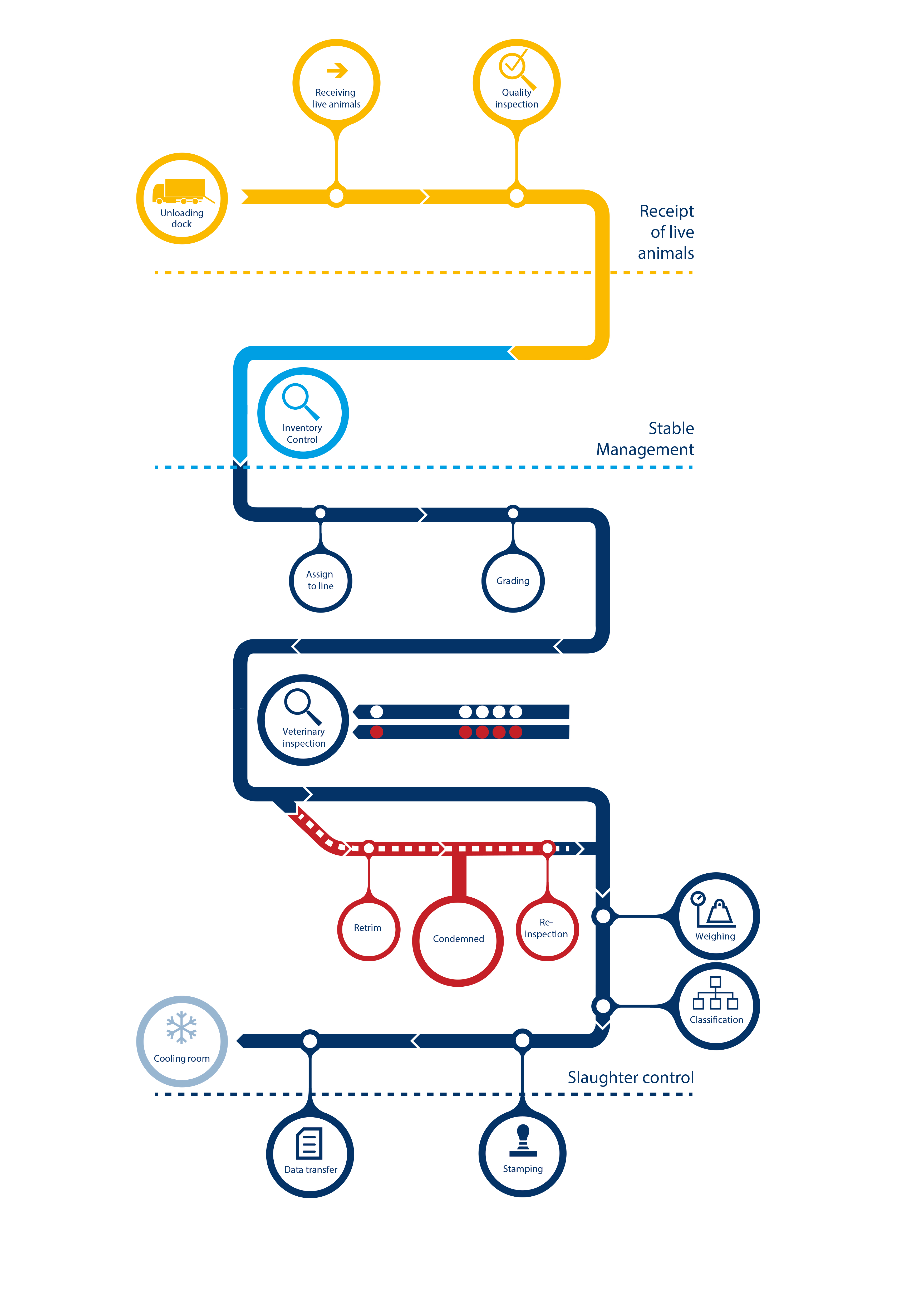

The Production Manager is concerned with product quality (including weight and lean meat ratio) and traceability. That role can track downgrade percentages and product rework, which can affect production if it exceeds a certain threshold. The Production Manager also pays attention to cool room capacity, a critical factor in production planning and order fulfillment. By deploying logistics software, the Product Manager can oversee the optimal sorting and storage of inventory, and assign carcasses for distribution accurately.

Maintenance Manager

The Maintenance Manager is tasked with minimizing downtime and quickly identifying the source of any problems across the operation. With the implementation of primary processing and logistics software, that role can use collected data to monitor availability, performance, and quality. The Maintenance Manager also can identify areas for improvement by tracking production trends.

Quality Manager

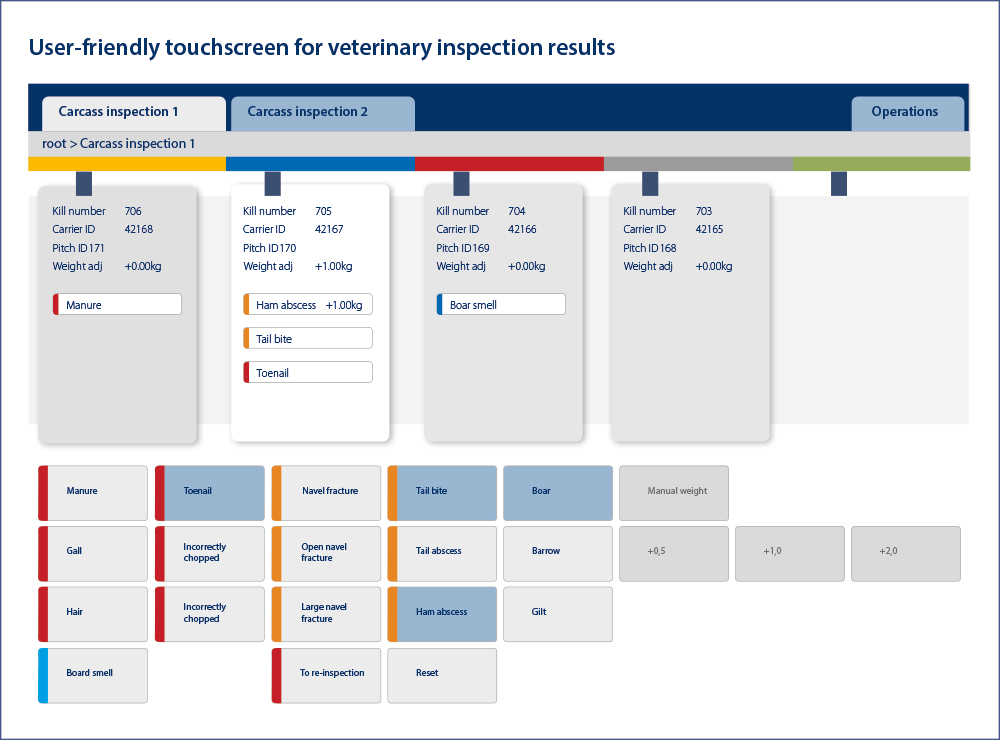

With Innova Pork Primary Processing software, your operation continually aggregates reliable quality data. This gives the Quality Manager live insights into production and traceability variables. That role can manage, add, and change quality parameters as needed to address production requirements. A Quality Manager is concerned with any data surfaced regarding downgrade percentages, and can use the software to verify that rework is properly executed.

Line Operators

Line Operators can employ practical tools available with these solutions to ensure process efficiency and traceability. They can assess the health of incoming lots, manage stable populations, observe veterinarian instructions for retrimming in the rework area, and carry out hot scale duties to determine the weight and classification of sides.