As the company that first paved the way for air chilling, JBT Marel has built on this position to remain the leading authority in the market.

With its long history in air chilling for the poultry processing industry, JBT Marel can be considered the inventor of modern air chilling technology as we know it today. As the company that first paved the way for air chilling, JBT Marel has built on this position to remain the leading authority in the market.

Back in the 1980s, sales of fresh chicken began to become more prevalent, especially in Europe. Stork PMT, JBT Marel’s predecessor, believed air chilling was the best solution for fresh products and partnered with another Dutch company in the Stork group, Stork Bronswerk. Stork Bronswerk’s area of expertise was heat transfer solutions. The company was particularly active in the military sphere but was prepared to investigate the possibility of coming up with possible solutions for the air chilling of poultry.

Stork PMT and Stork Bronswerk collaborated for many years and did poultry air-chilling projects together in many countries, principally in Europe. Eventually, in the mid-eighties, Stork PMT decided that the air-chilling of poultry was sufficiently important to involve itself in the design of systems. To do so, the company hired its main poultry contact at Stork Bronswerk to start designing air chilling systems by itself in Boxmeer. At the same time, Stork PMT was working together with a leading Dutch scientific institute to model and optimize the air chilling systems.

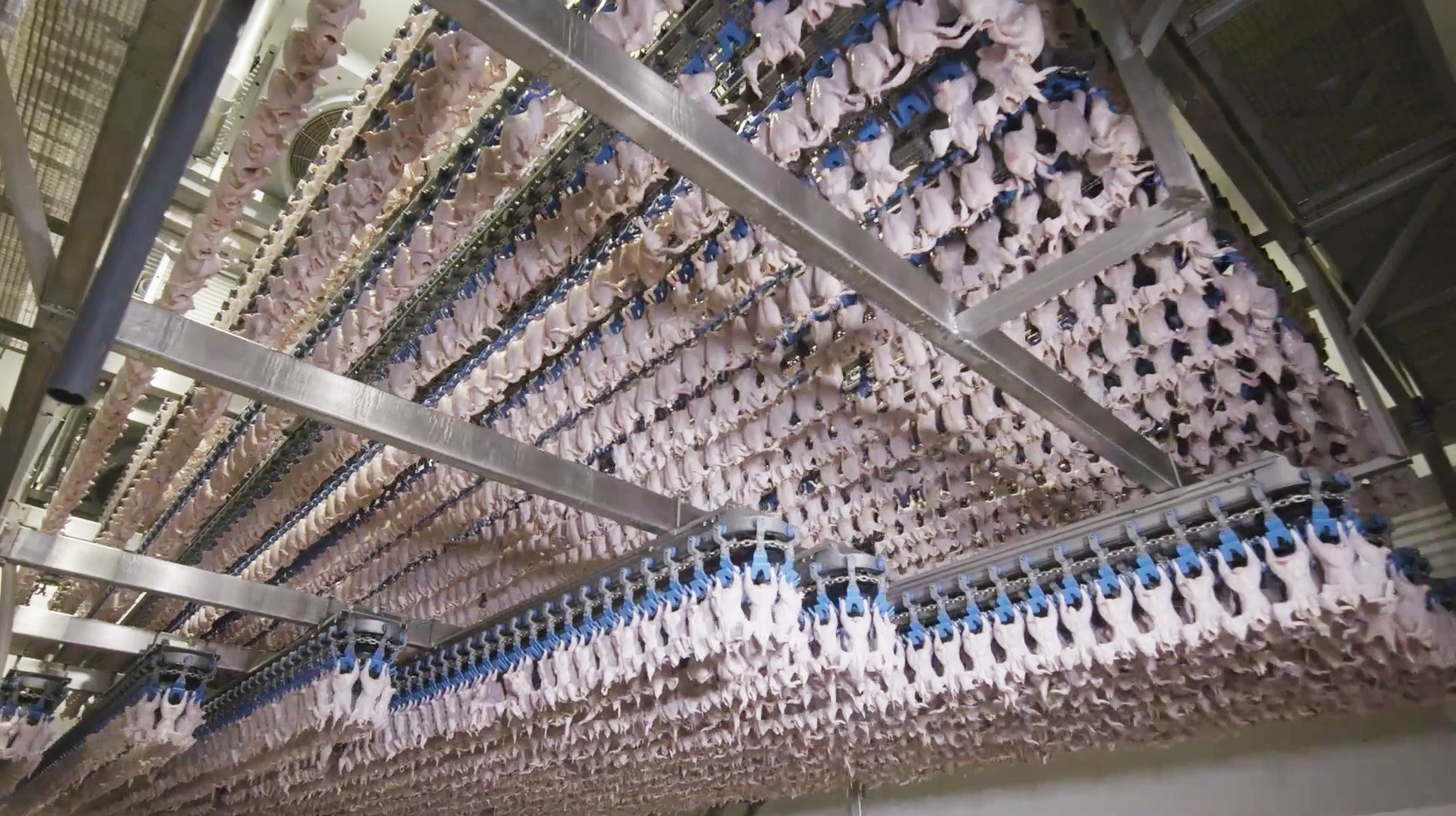

While some local static air chilling setups existed at the time, with products hanging in racks, Stork PMT’s initiatives show that the Boxmeer company can rightly be seen as the inventor of the modern air chilling tunnel as we know it today: air-chilling systems designed specifically for the poultry processing industry, using overhead conveyor systems with chilling shackles suspended from a chain and products staying in-line all the time, fully integrated in the processing line.

In the following years, these insights into the required technology allowed Stork PMT to further improve its air chilling systems and strengthen its market position, building on decades of expertise.

Today, JBT Marel continues that legacy as a global leader in air chilling solutions, helping processors in every part of the world deliver top-quality, safe, air-chilled poultry products. Almost every new poultry plant worldwide now chooses JBT Marel for air chilling, showing a remarkable track record in 2025. This year, at least four important greenfields, in Spain, Australia, Germany and USA, will be equipped with JBT Marel air chilling tunnels.

As the company that first paved the way for air chilling, JBT Marel has built on this position to remain the leading authority in the market.

Carcass chilling during broiler processing is a critical step in the process and JBT Marel has deep expertise in this area. Our installations show that JBT Marel is the authority in air chilling technology. Customers worldwide trust us to deliver consistent results, regardless of the size of the plant or the challenges of the market.

With every new greenfield installation, JBT Marel strengthens its position as a global leader. Processors know that choosing our air chilling technology means higher quality, safer products, and a stronger business.

JBT Marel knows very well the potential pitfalls of air-chilling, the freezing of thin parts and yield loss. With its Downflow Plus technology, more of which later, the company aims to create a micro-climate round the bird keeping yield loss to an absolute minimum. Where the temperature is measured is also important. JBT Marel measures in the core of the breast, the warmest part of the bird. JBT Marel is happy to give guarantees on final product temperature and maximum weight loss, also that the process will not freeze thin parts, resulting in the best possible product presentation.

JBT Marel offers three types of air-chilling installation. These are the DownFlow Plus system, Shock MaturationChill and InfraChill.

DownFlow Plus is a multi-tiered system on the top of which evaporators are installed. These evaporators blow cooling air obliquely onto the tiers below (therefore the name ‘down-flow’), which are offset to prevent products hanging on special chilling shackles from dripping on one another. Spray cabinets mounted at intervals apply a thin film of moisture to exterior, interior or both surfaces. The position and type of cabinet will depend on what the customer wants to produce, as each DownFlow Plus chilling installation is especially tailored to specific customer requirements. These requirements will include product weight, the temperature to which products should be cooled and the space available for the installation. Marel JBT will always come up with an ideal footprint, ensuring that product is chilled as cost-effectively and sustainably as possible.

For those customers cutting and deboning most products and focusing on tender breast meat, Shock Maturation Chill is the answer, particularly if used in conjunction with CAS SmoothFlow controlled atmosphere stunning system and RapidRigor in-line electro-stimulation.

Shock Maturation Chill has two air chilling processes in a single installation. In the first (shock) process, very cold air is blown aggressively onto products to quickly reduce surface temperature and stop the growth of harmful bacteria. At the same time, a film of water is applied to all exterior and interior surfaces in spray cabinets mounted at intervals to the overhead track. This aids cooling and prevents products from drying out. In the much longer maturation phase, air at a higher temperature is blown gently on products. The aim is to keep temperatures for as long as possible in the range for maximum enzyme activity essential for effective maturation. In total, products can be in Shock Maturation Chill installations for upwards of three hours.

Finally, Marel JBT can also offer InfraChill. InfraChill is a ducted system, which blows air from evaporators mounted at the side of the system directly into the product’s cavity, thereby reducing chilling time by a quarter. Unlike DownFlow, InfraChill is a single-tier system and will always have a larger footprint.

With each installation worldwide, JBT Marel further establishes its reputation as a leading supplier of the air-chilling technology. Customers can relax knowing that they will always supply a safe, top-quality fresh product. Yield loss will be the lowest possible. Presentation will be excellent. What is more, the execution chosen will reflect both the product which the customer wants to market and the space available for the installation, as each system is tailor-made. Customers choosing JBT Marel for air chilling technology can therefore do so with confidence.

News

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.