Software systems using data analytics help highlight opportunities for improvement in real time, so you can address issues as quickly as they arise, as well as over longer periods, so you understand trends and use them to inform your business strategy.

Advanced food processing software provides clear displays and records of production data in a user-friendly, centralized system. Standardized reports can be used efficiently and easily by all. And, as every business is unique, reports can be created to meet specifics needs. With data-driven insights you gain complete control of operations and make decisions that continuously improve production processes.

Does your production oversight feel like you’re driving a car without a fuel gauge?

Experience counts for a lot in improving production lines, but, even for the most experienced Production Manager there have always been surprises which, at best, cause bottlenecks or waste raw materials, and, at worst, bring production to a stop.

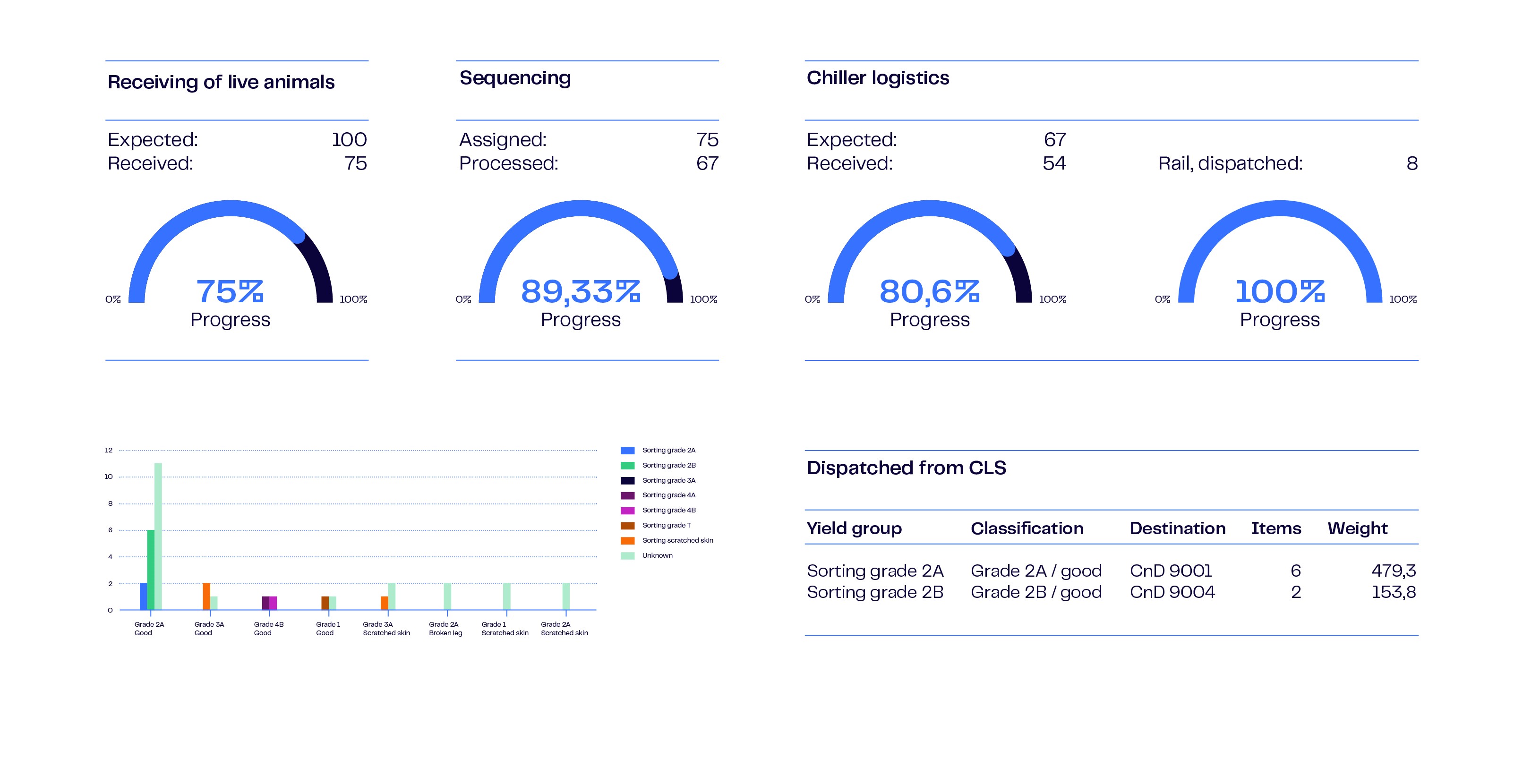

The latest dashboards display key performance indicators (KPIs) to monitor and control production in real time in easy-to-read graphs and tables. They give managers an insight into production lines they’ve never had before, enabling them to take action at the critical moment, to achieve the best results in food processing.