Turning a live broiler into a product ready for retail is a complex process with many steps. JBT Marel’s end-of-line solutions complete this process using advanced technology. They make sure every product is perfectly packed, labeled, weighed, and priced.

End-of-line solutions complete the process

JBT Marel's integrated approach to poultry packing and labeling

In the competitive poultry industry, the final steps of packing and labeling are very important. This is where profit, brand image, and consumer trust come together. Today, the end-of-line stage is not just about putting products into packages. It must be fast, accurate, flexible, and fully traceable. JBT Marel offers a full range of integrated solutions to turn the packing floor into an efficient and high-value part of the process.

Versatile and high-quality packing

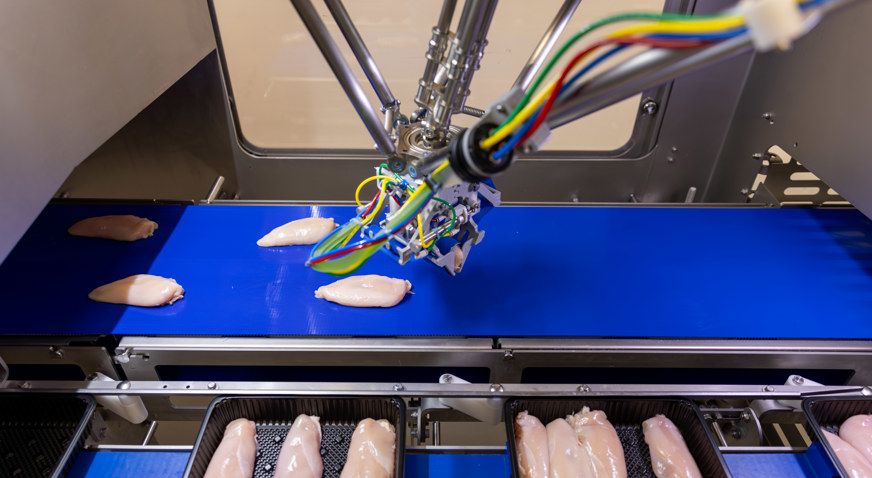

The challenge is to place the poultry end products into packaging that is secure, attractive, and meets customer specifications. JBT Marel addresses this with a range of automated packing solutions that prioritize product protection and shelf appeal.

It is crucial in this stage to be able to handle both catch-weight (variable weight) and fixed-weight batches with equal efficiency, ensuring that every final product meets exact specifications.

A standout solution for this challenge is the Marel RoboBatcher. This intelligent robotic system excels at creating fixed-weight trays of poultry products, such as fillets or drumsticks. It combines vision technology and advanced algorithms to select the optimal combination of individual pieces and meet the target weight of each tray with minimal giveaway. The robotic arms then gently place these products into trays—even styled—, ensuring both accuracy and a high-quality, neat presentation. The RoboPacker is a similar solution, but for catch-weight packing only.

Packing logistics

The end-of-line stage in the processing plant can be complex, with many different lines running and crossing each other. This can cause logistical bottlenecks. JBT Marel’s TrayTrack system removes these bottlenecks.It prevents people with bins and boxes from walking around, using stairs or bridges to cross processing lines. This helps avoid delays and also keeps other parts of the process running smoothly.

This intelligent tray transport solution ensures that trays are delivered precisely when and where they are needed. TrayTrack seamlessly routes the packed poultry to the next stage, such as sealing or labeling. By automating tray transport and creating a smooth, continuous flow, It reduces the need for manual transportation, while tying the packing process together.

Precision weighing, pricing, and labeling

Once packed, every item must be accurately weighed and labeled. This step is crucial for regulatory compliance, pricing accuracy, and the communication of essential information to the consumer. Marel’s Weigh Price Labelers (WPLs) are the industry standard for this task, such as the Marel WPL9000+. This high-speed system automates the entire process:

- Accurate weighing: Each pack is weighed with great precision, minimizing giveaway—no more product should be included than stated on the label.

- Automatic labeling: The system instantly calculates the price based on weight (for catch-weight products) or confirms the fixed weight. It then prints and applies a high-quality label with all necessary data, including weight, price, barcodes, clock-linked dates, and all relevant product information in multiple languages.

- Flexible application: The WPL9000+ can apply labels to any surface of the pack, even to uneven surfaces thanks to the contact applicator.

This WPL automation greatly increases speed and removes human mistakes from manual weighing and labeling. It ensures every pack is consistent and accurate, even at thousands of packs per hour.

End of end-of-line

After packing and labeling, the end-of-line configuration in a processing plant can be completed with a CheckWeigher, such as the MCheck2. This is the final check to make absolutely sure the pack conforms to stringent weights and measures legislation. It optionally also includes single and multi-frequency metal detection to ensure quality control.

The digital backbone

What truly lifts JBT Marel's offering from a collection of machines to a cohesive, intelligent system is the end-of-line software, which acts as the central nervous system.

- Centralized control: the software connects all the equipment, from packers to labelers. From a central point, operators can manage packing orders, define label layouts, and monitor the performance of the entire line in real-time.

- Data-driven: The software collects data from every step, providing managers with valuable insights into key performance indicators like throughput, giveaway, and OEE. This data empowers them to make informed decisions to optimize processes and reduce waste.

- Full traceability: In times of food safety concerns, the end-of-line software provides full traceability. It tracks each product from its source through processing and into its final package, ensuring that in the event of a recall, items can be quickly and accurately traced.

Holistic approach

The power of JBT Marel end-of-line solutions lies not in any single machine, but in their integration. You can configure a complete end-of-line process where raw products enter and come out as perfectly packed, weighed, and labeled products, all managed and monitored by software.

This holistic approach delivers various benefits. Automated end-of-line processes minimize the need for manual handling, freeing up staff for more value-added tasks. High-speed, interconnected machines ensure an efficient flow with no bottlenecks. And finally, precision weighing, combined with software control, reduces product giveaway, boosting yield and profitability.

In conclusion, JBT Marel offers more than just equipment; we give you a real business advantage. With strong and flexible packing solutions, precise weigh-price labeling, and smart software control, we help you reach the highest standards of quality, efficiency, and food safety—so you can succeed from the plant to the consumer’s plate.

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.