In an interview with Chilean industry publication Aqua Magazine, Marel Sales Manager in Fish Marco Arevalo discusses how new robotic solutions automate the packing process and increase efficiency and food safety. Read more in the translated transcript below:

RoboBatcher featured in Aqua Magazine

Chilean fish industry magazine features RoboBatcher series in article about automation in packing

Fish Sales Manager Marco Arevalo discusses how Marel’s robotic solutions automate the packing process and increase efficiency and food safety

The future is robotic

New solutions that automate packing processes, increase efficiency and safety due to minimal human contact with the products.

The food industry has had to adapt to increasingly demanding consumers in recent years. The salmon processing industry has experienced remarkable advancements with new technologies that have led to much of the industry's automation.

Packing is a part of this and, although it sometimes goes unnoticed, significant progress is also being made at this final stage of production. For example, new trends in packing materials are emerging, including those that are more sustainable and/or biodegradable. Similarly, greater emphasis has been placed on automation and applied technology to facilitate work in current times.

In this sense, the adoption of intelligent automated systems results in greater food safety, a significant reduction in labor costs and the elimination of the risk of error and human dependence that can be detrimental to a production line.

The salmon industry has focused its attention in packing on intelligent, automated filling and labeling systems to minimize human handling and reduce overweight packaging.

A variety of solutions

The aquaculture industry has a number of companies that provide technologies for processing, several of which have solutions for the packing process.

One of the more notable companies with extensive experience in food and fish processing equipment is Marel, with their advanced solutions and integrated systems for the salmon processing industry.

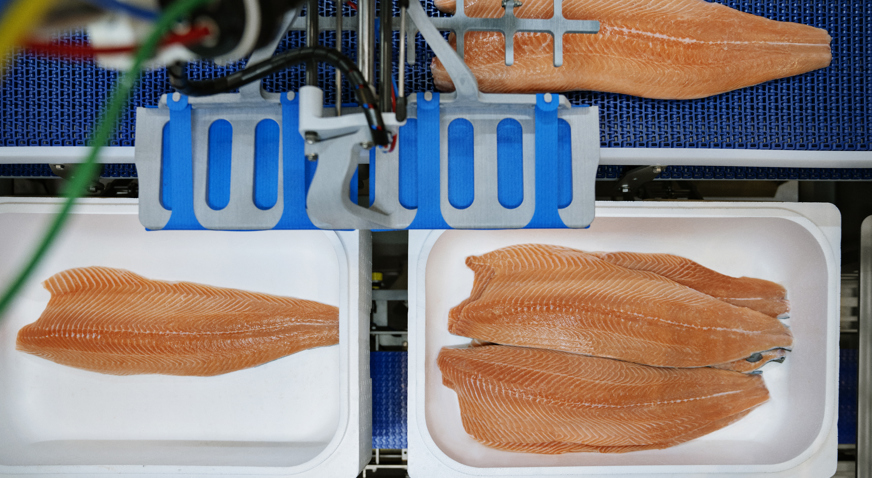

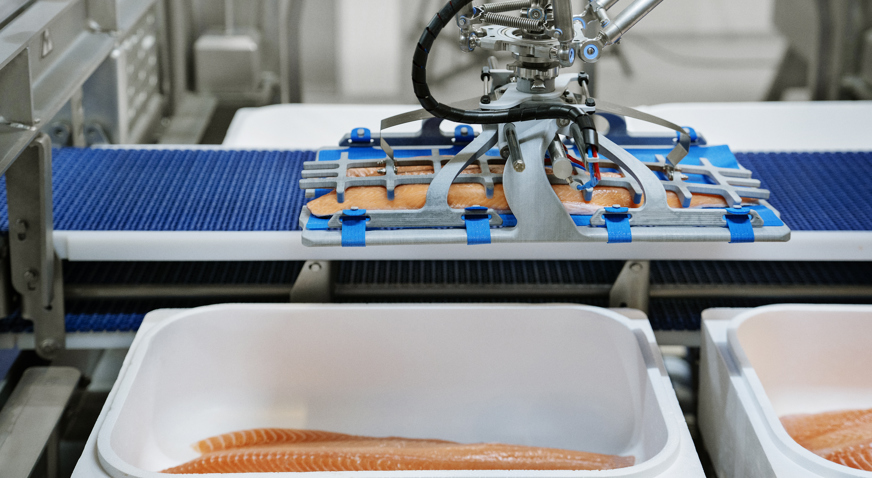

Among the many innovations at Marel is the RoboBatcher series that “combines state-of-the-art sorting software and innovative robotic technology to style and pack fish into trays, thermoformer pockets or fixed weight boxes. Its unique grippers are designed to handle the product delicately, ensuring that even the most fragile fish is not damaged during packing, "says Marco Arévalo, Marel's Sales Manager for the fish industry.

Marel offers innovative equipment, systems, and software for the processing of whitefish and salmon, both aquaculture and on-board. Its objective is to maintain and strengthen its position in the secondary processing of salmon, including filleting, distribution, as well as to enrich its current offer in the primary process. The company has a wide range of service solutions that adapt to the specific needs of each processor and maximize productivity throughout the production line, from beginning to end.

The challenges in the pandemic

The packing industry has not been without challenges during the COVID-19 pandemic as the world races to vaccinate as many people as possible. The labor issues that processors have faced, including the lack of operators and the reduction in human contact with products, have meant that automation has never been more critical in the salmon processing industry.

"Since the beginning of the COVID-19 pandemic, the industry has faced challenges such as employee health and safety, changes in market demand and maintaining the flow of production," says Marco Arévalo, from Marel. "Automation reduces reliance on manual labor, combating rising labor costs, labor shortages, and social distancing measures."

Greater efficiency

In the case of Marel, the RoboBatcher solution manages the flow of cash, accelerating processing and optimizing performance and efficiency in fixed weight batches, thus improving what a human group can do.

"For example, the RobotBatcher Box (automated box packing system) automatically styles and packs up to 24 boxes simultaneously, with up to 12 predefined jobs, in polystyrene and cardboard boxes for retail, catering and others," as reported by Marco Arévalo.

Future projections

While the future is uncertain due to all the expected changes because of the pandemic, packing companies have their sights set on automating all processes.

Marco Arévalo agrees with this and explains that "the use of robotics and intelligent systems with software control in the salmon industry allows an infinite number of applications in the different stages of processing. For more than 30 years, Marel has produced innovative equipment and solutions for the fish processing industry that have improved yield, quality and production throughout the production chain for countless customers."

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.