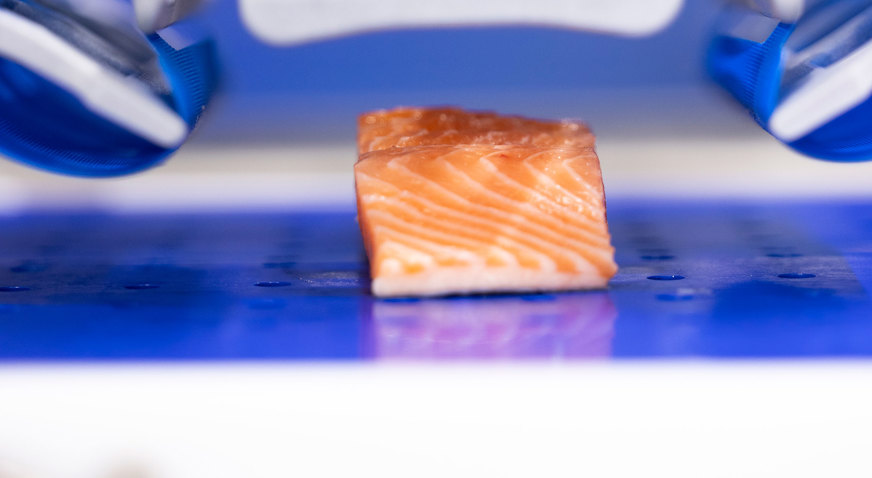

RoboPacker is here! JBT Marel’s latest innovation in advanced robotics is designed to reshape packing lines and become the perfect companion for salmon processors worldwide. Reducing labor dependency, improving throughput and providing excellent styling, the RoboPacker automates the manual task of packing and styling catch- or fixed-weight salmon portions into trays. Not only enhancing efficiency but also improving food safety standards.

RoboPacker is the future of catch- or fixed-weight packing automation

The new, game-changing innovation in automation for catch- or fixed-weight packing of salmon portions into trays. RoboPacker is ready to revolutionize salmon production line with more efficiency, less labor and perfect styling.

The journey towards RoboPacker began more than twenty years ago:

- 2014 - RoboBatcher Flex

- 2017 – RoboBatcher Thermoformer

- 2019 – RoboBatcher Box

With each innovation the RoboBatcher robotics have solved challenges for fish processors with increased automation. In 2025, over 350 JBT Marel robots will handle 3.8 million pieces of protein, saving processors worldwide, millions in product optimization and operational efficiency.

Our latest innovations provide gentle gripper technology, improved hygiene to keep product quality at its highest.

Excellence built on legacy

The RoboPacker builds on this decades of expertise, taking automation to the next level and revolutionizing the packing of catch- or fixed-weight salmon portions into trays for salmon processors.

Increase efficiency: Pack up to 120 pieces and 80 trays per minute, 24/7. Boosting throughput while reducing labor costs and human error.

Styling flexibility: Easily choose between styling patterns. Presenting products in the most appealing way possible.

Precision and consistency: A 3D vision system ensures accurate placement of each piece and enables minimum target weight packing. Keeping yields high and waste low.

Optimal hygiene: Clean with speed and precision. Hygiene built in through every step of design.

Seamless integration on every level

As the trend towards automation continues in salmon processing, it is crucial when developing new solutions to ensure they can integrate seamlessly into operating production lines. The RoboPacker has a small footprint so it can easily fit into most spaces. Its operating system works smoothly with third-party tray handlers and a variety of tray formats, from cardboard to polystyrene. And it seamlessly connects with JBT Marel operating systems, such as the I-Cut 130 PortionCutter, adding more value and control to the packing processing.

The RoboPacker that specializes in salmon

With the RoboPacker, salmon processors are getting a cutting-edge solution that adapts to needs, improves operations, and ensures reliable, high-quality packing. The RoboPacker isn’t just a machine; it’s part of JBT Marel’s commitment to transforming salmon production with smarter, more efficient solutions.

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.