The aim is to equip robot technology with generic capabilities in active perception, world modeling, planning & control and gripping & manipulation. Project leader prof.dr.ir. Eldert van Henten of Wageningen University & Research talks about the current state of affairs.

The program involves three groups of industries, greenhouse cultivation, biscuit and chips manufacturing and poultry processing. For all three use cases, the research program will demonstrate new technologies, which will progressively move forward from university laboratory to industry factory.

Areas of expertise

The Wageningen University & Research (WUR) will lead the way and all universities will bring in their particular areas of expertise. The active perception part is being taken care of by University of Amsterdam and WUR; TU Eindhoven and WUR together tackle the world modeling subject. Planning and control will be the area for TU Delft and TU Eindhoven to excel, while TU Twente and TU Delft will cover the gripping and manipulation chapter.

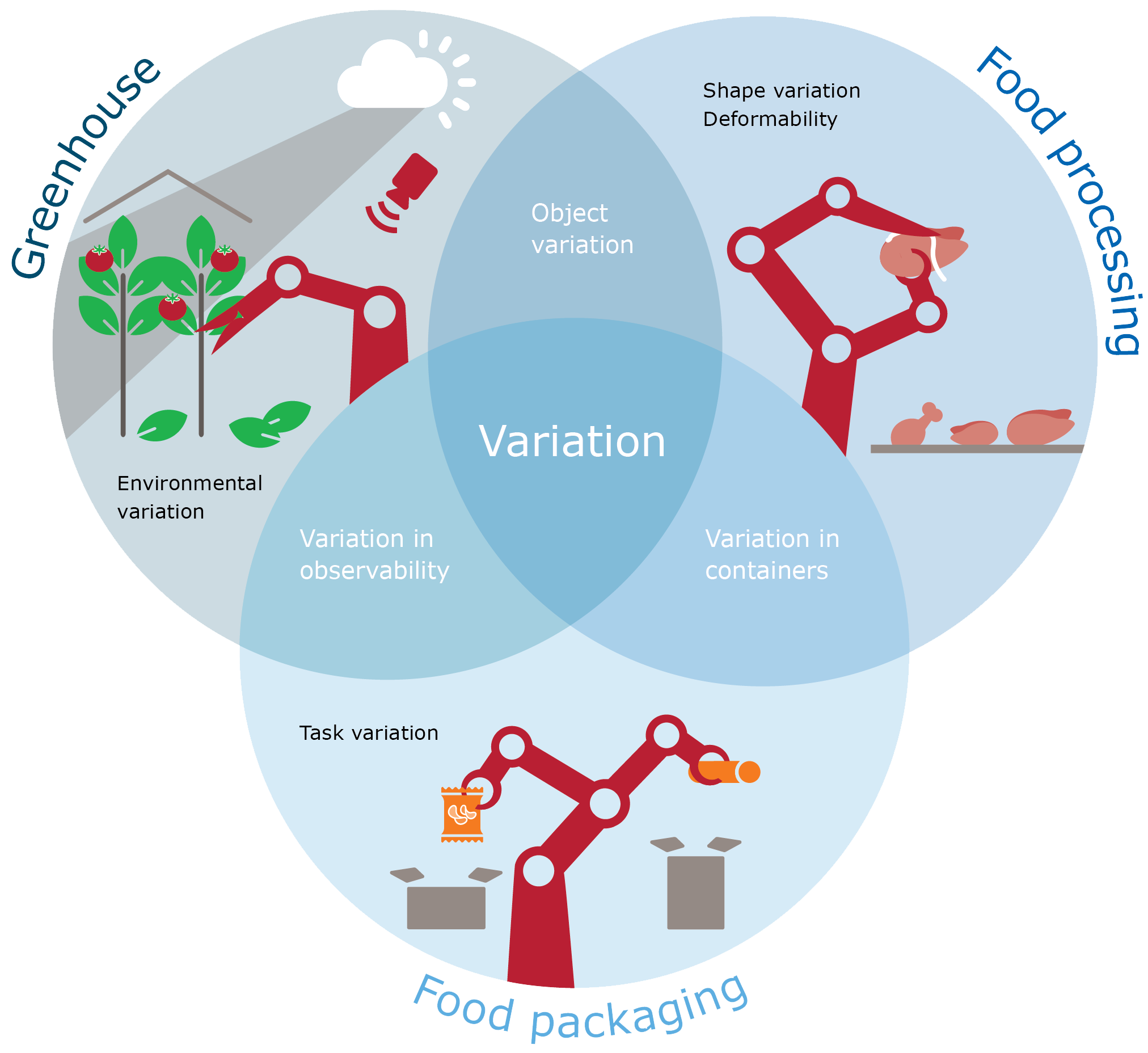

Variation and complexity

The poultry industry features an enormous amount of technology, but the processing line still requires quite some staff. People particularly work in environments that require multitasking. Precision, product variation and complexity play a role here. Until now dealing with these issues has been a human monopoly. Technology needs to make a considerable step forward to take over these tasks.

“Regarding variation and complexity, robotics in the automotive industry have made gigantic leaps in the past decade,” says Eldert van Henten. “We want to achieve the same progress for the poultry industry. We can use what’s available and further develop that for the agri-food domain.”