"Compared to standard polyacetal, which is common in side-flexing conveyors, EnduraBelt offers superior chemical resistance and strength."

The efficient, fast, robust and food-safe transport of products with minimal transitions is crucial in processing plants. Fresh meat quality depends on protein-specific, non-sticky belt material that reduces touchpoints, preserving meat integrity and extending shelf life. JBT Marel’s unique EnduraBelt conveyor material, specially designed for its Systemflex systems, strikes the perfect balance between functionality, technical innovation, and cost-efficiency—delivering a smarter, safer and reliable transport solution even in the most complex logistic environments.

In poultry processing, logistics are becoming increasingly complex, Based on their quality and other characteristics, products must be routed to their best destination. A reliable, robust, and smooth transfer from A to B remains the top priority for any logistics system.

Minimizing transition points on a conveyor belt is crucial for product integrity and shelf life. Each transfer adds a new contact point. This increases the risk of contamination, half of which comes from the product itself. Keeping products on a single EnduraBelt reduces contact points and enhances both efficiency and food safety.

By reducing the amount of product-to-belt contact, EnduraBelt solves multiple challenges at once. It minimizes protein adhesion, reduces contamination risk, and needs less cleaning. And once cleaning is required, SystemFlex EnduraBelt ensures that this is easy.

Usually, conveyor belts work in a cold environment of 2 to 4°C, while cleaning happens with cleaning agents, chemicals and chloride concentrations at temperatures, which can go as high as 50°C. The belts cool down once again to 3°C. EnduraBelt material weathers the chemical and mechanical strains of cleaning very well, which results in long belt life.

All usual belt materials have challenges as far as chemical resistance is concerned. What makes EnduraBelt unique is its new, revolutionary thermoplastic polymer material, offering an exceptional combination of performance characteristics. It not only has much higher chemical resistance to chlorine but also features stronger mechanical properties. Combined with its modular design, this results in considerably increased tensile strength, enabling the design of conveyor systems with minimal transition points. With wear and tear significantly reduced, EnduraBelt has a longer life, even under harsh conditions.

Developed in collaboration with Ammeraal, EnduraBelt belt material combines the best of both worlds, bringing together essential expertise—where the conveyor specialist meets the poultry system integrator. That’s why moving poultry meat from A to B is EnduraBelt’s sole purpose. This material reduces sticking issues, as it has a smaller contact area. This ensures improved product release. Unlike solutions designed to accommodate a variety of food products, the fact that EnduraBelt was designed to transport meat is critical.

EnduraBelt’s design significantly improves safety. Most modular conveyor belt materials have open edges on the sides, creating a potentially unsafe situation for the operator, for example when an operator’s sleeve gets caught. This is a known safety risk but until now, the only solution available on the market was adding safety guarding, which then creates an obstacle for cleaning. EnduraBelt is safe, thanks to its fully closed edges with no catch or hang up points and no need for safety guards.

EnduraBelt makes the life of processors also easier with its SmartRelease system for making quick adjustments. In case there is an issue, for example a snapped belt, it is easy to fix. Usually, it is quite a hassle to disassemble the linking pins, especially in a cold environment. EnduraBelt only requires one handy tool, the SmartRelease, to detach the belt in a second, swap it and put it back. The line will be running again in a matter of minutes. This is important, because reducing downtime is key.

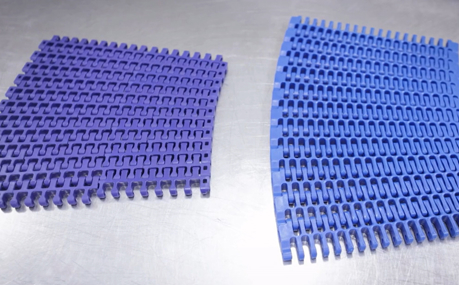

Left: the existing belt material. Right: Marel’s EnduraBelt material with unique closed edges. There is no risk of staff getting caught on the belt with clothes or anything else. The risk is also minimal that the moving belt gets damaged if it hits an unexpected obstacle. All this means the safety level is much higher than with other materials. Besides that, the belt is reversible, with identical top and bottom sides, making confusion impossible.

In a logistics system, SystemFlex now uses only half the number of drive units. This means many advantages in terms of investment level, COO, breakdown risk, energy use and heat generation. The electrical set-up is less complex. A SystemFlex logistic system is therefore easier to install.

SystemFlex allows for more complex logistics solutions, which require more ups, downs and curves. Thanks to the increased tensile load, longer belts are possible. These remain robust at high speeds. Belt speeds of 30, 35 meters a minute are possible, with a smaller number of transition points, longer conveyors and a minimum of drives.

JBT Marel has developed a calculating tool, Belt Force Calculator, to measure and forecast how many drives are needed in a factory. That is because all components are predictable. Another tool, Belt Force Indicator, can give feedback on the actual performance of each conveyor system.

Tensile load is an important factor when wanting longer conveyors without transitions. This means fewer drives and lower costs. Allard Martinet, Director Products JBT Marel Poultry, says, “We have doubled the tensile load so we can have twice the length of the conveyor. Instead of the current maximum length of 15 to 18 meters we can handle 30 to 36 meters. We also reduced belt friction by up to 40%. This is especially important in horizontal curves, where friction is highest. For some applications, like robots, the belt needs to accelerate further. For these purposes, the belt can speed up to 45 meters per minute. Finally, we can tackle more complex logistical challenges using solutions with a smaller footprint.”

One of the unique benefits of SystemFlex is that it takes just two motor types to handle all the different conveyor setups. These can have different belt types, belt widths, belt speeds and can be in a variety of layouts. The difference between the two motors is related to speed and torque. A higher speed is typically needed for speeding up the conveyor in front of a robot. Standardizing drives means a significant advantage for maintenance departments.

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.