The strength of a digital backbone

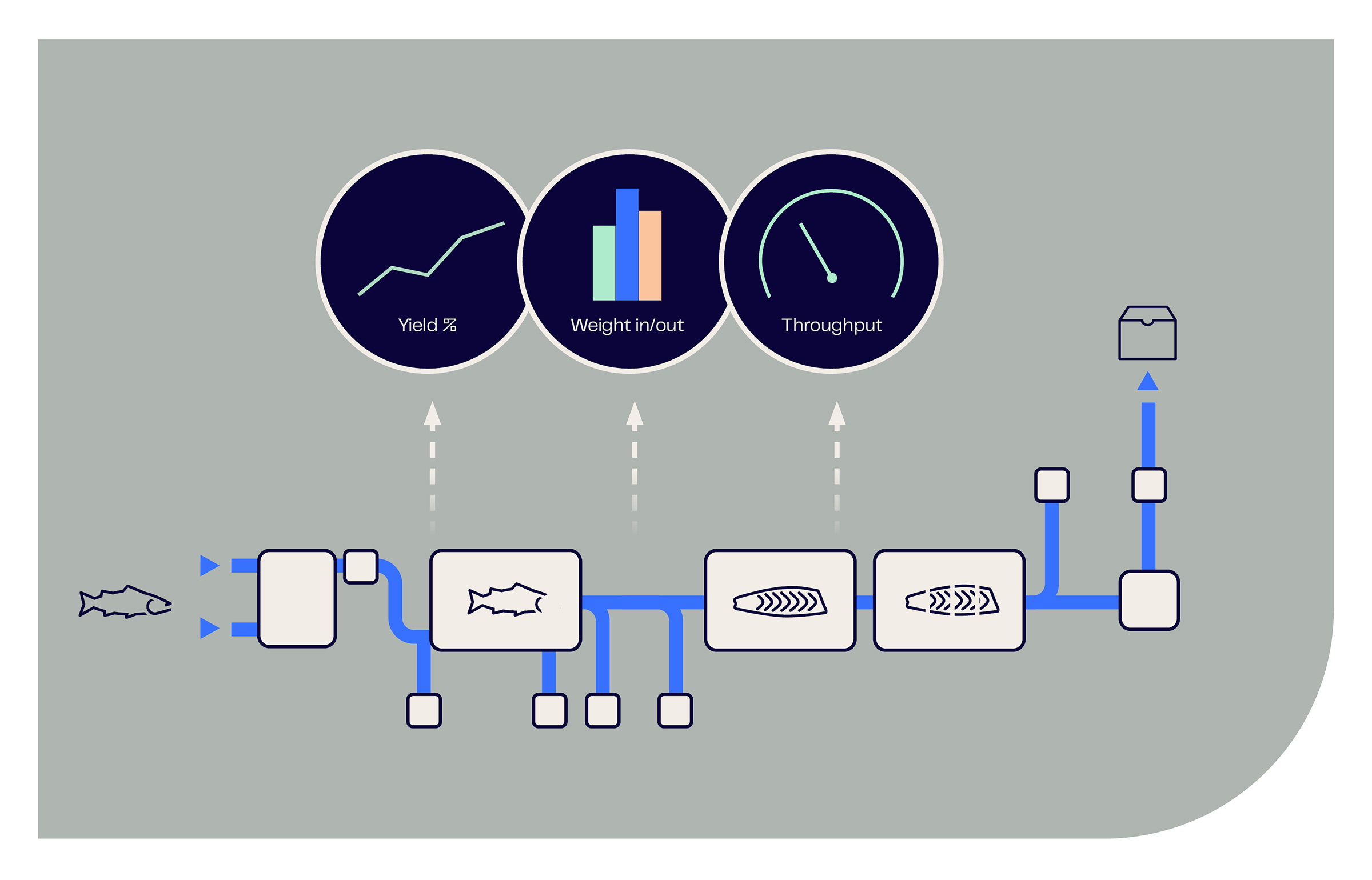

The digital foundation of the Salmon Filleting Solution transforms real-time and historical data into actionable insights. It seamlessly integrates with machines in both fully automated lines and more simple setups to track metrics like yield, throughput, trimming performance and equipment status. With this crucial insight, processors can make smarter decisions across filleting processes and dramatically shift production results.

- Gain production insight in real-time

- Improve consistency in product quality

- Reduce yield loss

- Maintain compliance with evolving regulations

"Every gram counts,” Parrish states. “With differing fish sizes, operator trimming styles, along with throughput bottlenecks, there are countless variables that impact yield and traceability. Processors need food processing software that turns that complexity into clarity.”

Real-world results

At Lerøy Midt, one of the world’s most advanced salmon processing facilities, five filleting lines are powered by JBT Marel Software. “If we compete with the lower‑cost countries, we have to automate the production and reduce the number of people in the lines,” explains Pål Kleven, Production Director at Lerøy Midt. “If not, we can’t compete. We have to be in the first line to develop new technology together with the suppliers.”

When Chilean processor Salmones Camanchaca SA upgraded their processing facility integrating software with high levels of automation they saw gains which reflected the adoption. “We invested in a Marel filleting line to improve our processing results. We have experienced an improvement of around 30% in productivity since the installation, with at least a 1% gain in yield,” explains Jorge Fernández, CEO at Camanchaca.

Advanced production control for yield optimization

When 1% improvement in yield can equal hundreds of thousands of dollars, optimization is about understanding and managing every component of each salmon, not just the fillet. The Salmon Filleting Solution achieves this by integrating with advanced equipment such as the Salmon Deheader MS 3028, the Filleting Machine MS 2730 and the Filleting Machine MS 2750. The machines automatically adjust to fish sizes and ensure cutting accuracy, while the software extracts data to drive optimization.

Key capabilities:

- Real-time process monitoring

- Precision fillet weighing

- Byproduct weighting

- Line throughput monitoring

- Yield percentage tracking

- Instant alerts for deviations