Information

Are you experiencing a gradual growth of your cut-up production? Is your market gradually moving from whole bird to chicken parts? Is your volume of cut-up parts getting too big to handle manually? Then it’s time to take the first step in cut-up automation. Marel’s ACM-NT Compact is an easy-entry, “slim fit” cut-up system that will always match your budget. It is your perfect ticket to the world of automated cut-up.

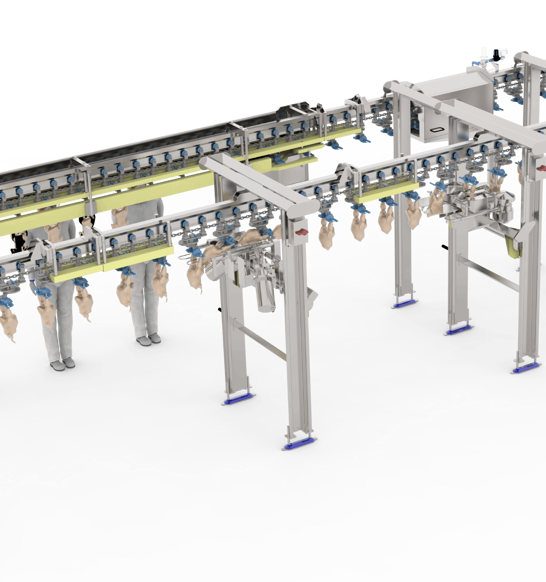

Flexible set-up

It’s all up to you how you want to set up your ACM-NT Compact cut-up system. Its flexible layout allows you to head out in all directions. It all depends on what kind of end products you want to produce. Do you have a focus on wing products, leg products or breast products? Once you’ve chosen the appropriate modules that comply with your customers’ end products demands, ACM-NT Compact does what it needs to do and fulfills all your product needs.

Countless options

ACM-NT Compact takes into account your space availability. You can choose from one of the three standardized overhead steel frames, all offering a compact footprint. Even when space in your plant is at a premium, ACM-NT Compact will still fit in.

Each ACM-NT Compact system can be different. It can be a straightforward set-up, featuring all essential modules for wing, leg and breast cutting. Or it can be a specialist configuration dedicated to leg processing (including JLR anatomic leg cutter) or wing processing (including Wing Tipper, Wing Joint Cutter, Whole Wing Cutter). Your options are countless. You can produce any specific cut-up product your customers ask for.

Shackling products and, if necessary, bypassing modules are simple manual processes. The maximum capacity depends on shackling speed, usually 6,500 products per hour.

Upgrade

Your first investment in your ACM-NT Compact system – custom designed to match your budget – will immediately give access to first-class automated cut-up, making use of the same modules as a full-blown ACM-NT solution. If your customer demand grows, you can easily upgrade with gradual investments in time. By adding weighing, grading, selective cut-up and distribution based on software control, your modular system can develop from straightforward production of chicken parts into a powerful in-line ACM-NT cut-up solution, fulfilling multiple cuts intelligently and simultaneously without manual interference.

- Flexible, modular set-up

- End product choice is decisive for the configuration

- Cut-up modules feature proven ACM-NT technology

- Performing the highest percentage of A-grade cuts in the industry

- Three standard overhead steel frames for smallest footprint

- 6,500 bph maximum capacity

- Manual shackling

- Manual bypassing of modules possible

- Upgrading to fully automated ACM-NT is within reach

- Limited investments