Information

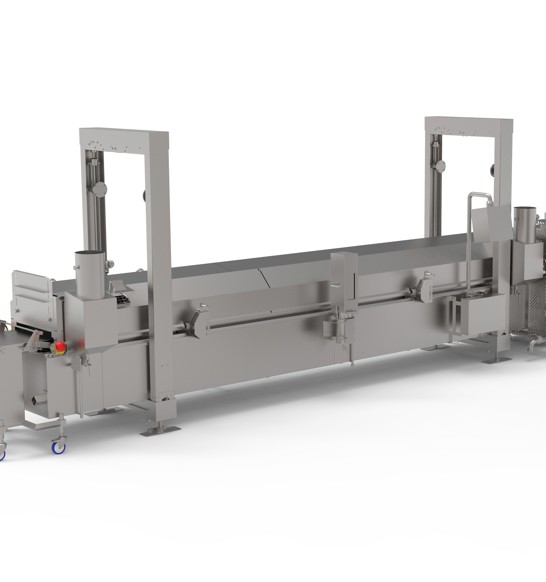

The GoldFryer lies at the heart of a completely integrated system offering an optimal frying environment as well as oil management, filtration and storage. It produces uniformly fried products with the perfect color, texture and taste and exceptional coating adhesion.

Stable frying climate for uniform products

The oil flow in the GoldFryer has the highest circulation speed in the industry. This ensures a highly stable frying environment and maximum transfer of heat to products. You can be confident that your products will be fried uniformly and will always meet the most stringent food safety standards. In addition, the GoldFryer uses a uniquely adjustable plate to give you a higher level of control over oil direction to ensure your products are handled gently and coatings are not damaged.

Fast and efficient sediment removal

Residual sediment is removed efficiently at the outfeed end of the fryer. There is also the option to have additional sediment removal earlier in the frying process. The GoldFryer’s high oil flow means particles are removed quicker, giving you significantly cleaner frying and greatly extending the life of your oil.

Optimum filtration—optimum product quality

Whatever your product and whatever its coating, the GoldFryer can be equipped with exactly the right filter to ensure optimum particle removal and minimum oil degradation. Our filters range from the simple through to unique high tech solutions, including a full-flow filter system that, in combination with the high oil circulation, can quickly filter particles from the oil. You can select the right filter for you based on capacity and the type of products you want to fry.

Worry-free oil management

A high-tech oil management system automatically manages all oil flows to and from the GoldFryer and the system’s storage tanks and filters before, during and after production. It also allows you to mix oil from different tanks to achieve optimum usage and oil quality. Everything is controlled from the GoldFryer’s touch screen ensuring unmatched levels of safety when compared to managing the process manually.