Information

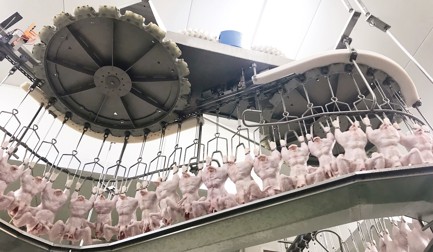

LineLink transfer systems are suitable for capacities up to 15,000 bph. LineLink EC transfers products from the evisceration line to the chilling line. Not only each product, but all information collected on it is transferred too. LineLink automatic inline transfer helps optimize product hygiene and ensures full traceability.

One to one transfer

Both lines run at exactly the same number of shackles per minute. Products are transferred on a one to one basis, preventing empty shackles downstream. In this way products are transferred correctly by both legs and are properly positioned for the next process.

Products locate into the system’s units. A large part of the carousel’s circumference is used for lifting products carefully from the evisceration shackle. On arrival at the transfer point to the chill line, the system’s units guide products into the chill shackle.

Ultra-reliable coupling

Line forces are synchronized electronically by the Active Tension Control (ATC) system. ATC compensates automatically for differing chain stretch on the two lines. Only in this way, both lines always run at precisely the same number of shackles per minute and ultra-reliable coupling can be achieved.

More chilling capacity

Full synchronization of the evisceration and chill lines means that plants laid out for a chilling line which runs faster than the evisceration line can now gain more chilling capacity, an additional benefit which comes free with the installation of LineLink EC.

If SmartWeigher and IRIS assessment systems are installed in the evisceration line, LineLink EC ensures that the weight and quality information collected on each product stays with it through the chilling department. These data can be used for production order planning and downstream processes.