Information

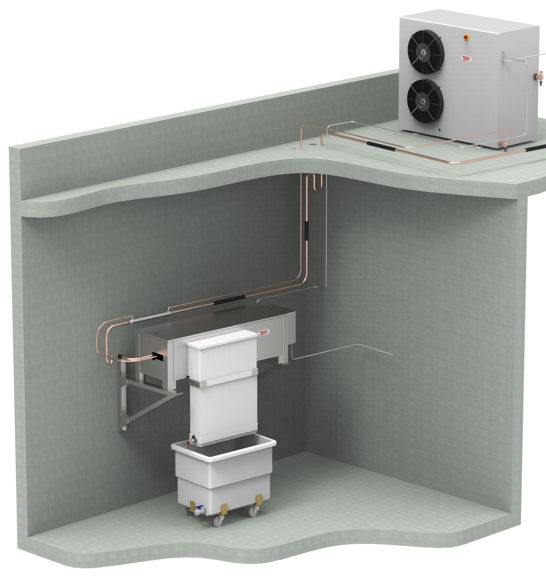

The flake ice lines MAJA RVH-L (for standard temperatures) and the MAJA RVH-LT (for higher temperatures) offer a wide choice of ice producing units, ranging from 250kg ice output up to 12,000kg every 24 hours. This split version is the ideal solution for all installations where the ice-producing unit and the condensing unit must be installed in separate locations. For example in fish and meat processing companies, bakeries or supermarkets and various non-food applications.

Hygienic, food-safe ice production

MAJA flake ice machines are labeled HY-GEN protected. This stands for excellent sanitary conditions:

- Easy access to cleaning relevant parts from all sides without the use of tools

- Easily removable, round plastic water tank

- Water tank without built-in parts, angles, edges and screws, allowing for easy and thorough cleaning

- Automatic water pipe rinsing after 24 hours without ice production

- Special hygiene advantages in accordance with the German drinking water regulations

Refrigeration

- Separate condensing unit in weather protection housing in galvanized steel Silent, solid and service-friendly solution with good access for maintenance

- RVH 9000 /12000 L/LT consist of two separately operated rotating evaporator units for individual control of ice output, according to varying needs and high operational safety

- Made for operation with the fluorinated greenhouse gas R449A (GWP 1397)

- Supplied without refrigerant filling. The refrigerant charge and the resulting CO2 equivalent (CO2e) must be determined during its startup

- Air-cooled condensing unit in L or LT version for different ambient temperatures

- With heat exchanger for optimum energy efficiency

- Electronic condenser fan speed regulator for automatic adaptation to variable ambient temperatures

Easy operation for convenient ice handling

- Easy operation by control panel ON/OFF for remote operation

- Control panels with program functions are optionally available

- Reliable SPS control unit

- Solid machine structure, frame and housing in stainless steel