Information

Whether you’re an artisan baker or producing bread on an industrial scale, the MAJA VS 07 can help you increase efficiency and accuracy in the dough making process.

Full process automation

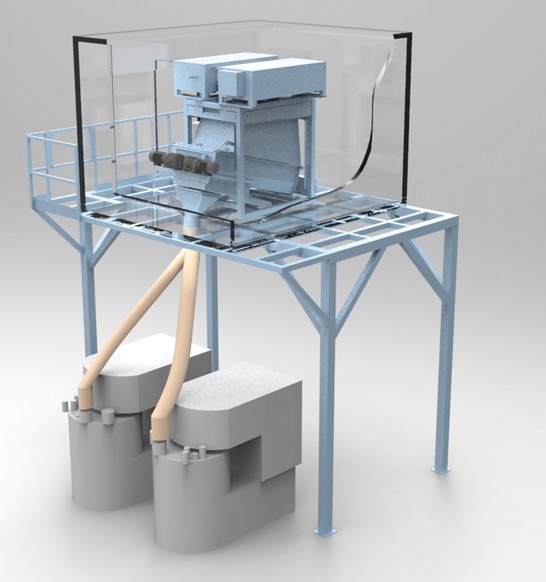

Traditionally, ice is added during the kneading process by scooping and weighing flakes manually. The MAJA VS 07 automates this process. It automatically produces, stores and distributes the exact amount of required flake ice directly into your mixers, at precisely the right time. It significantly reduces the manual workload allowing you to increase the speed and accuracy of your dough production.

Optimum freshness and quality

Depending on your requirements, one or two MAJA flake ice machines can produce ice directly into the MAJA VS 07’s compact silo system. It has a capacity of up to 300 kg and is designed so that ice is stored for the shortest possible time and can always be added when it is at its freshest to create the highest quality dough. Manual handling of the ice flakes is completely avoided, which greatly improves hygiene standards.

Precise portion control

Inside the silo there are discharge screws, which dispense batches of ice to a predefined weight with the highest accuracy. Both the size of the batch of ice and the discharge cycles can be individually defined by an operator or the system can be integrated into your production line and managed by recipe control software.