Information

Fully automated box packing and styling

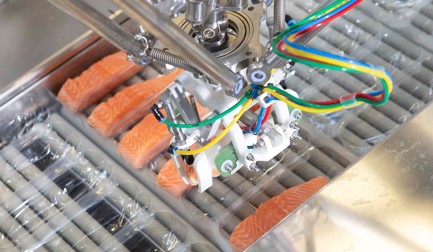

The RoboBatcher Box packs and styles salmon fillets and whole loins into polystyrene and cardboard boxes, directly after cutting, according to precise fixed-weight or catch-weight requirements and a predefined styling pattern. Fillets can be packed skin to skin or meat to meat.

Packing salmon according to grade, into catch-weight boxes

The system uses a unique combination of innovative robotic technology and state-of-the-art batching software, to pack boxes to a specific count. Any pieces that are out of spec can be removed from the stream for further processing, improving quality control and yield.

High-speed robotic processing of multiple jobs

With unmatched speed and accuracy, the system can handle up to 24 boxes simultaneously, with up to 12 different predefined jobs for retail, catering and further processors. It uses a unique packing technology to manage the flow of boxes, streamlining processing and optimizing throughput and efficiency like never before. It fully automates the dispatch process, ensuring that once a box reaches target weight it is immediately conveyed out of the robot and automatically replace by another.

Automation to minimize labor

The system virtually eliminates manual handling from the packing process so you can provide whitefish of the highest quality and with optimal hygiene. It has unique grippers specifically designed for gentle product handling capable of flipping the fillets for packing skin to skin or meat to meat, ensuring even the most fragile fish isn’t damaged during packing. It also significantly reduces your reliance on manual labor, making your production process more secure and reliable.