Information

Fully automated whitefish packing and styling

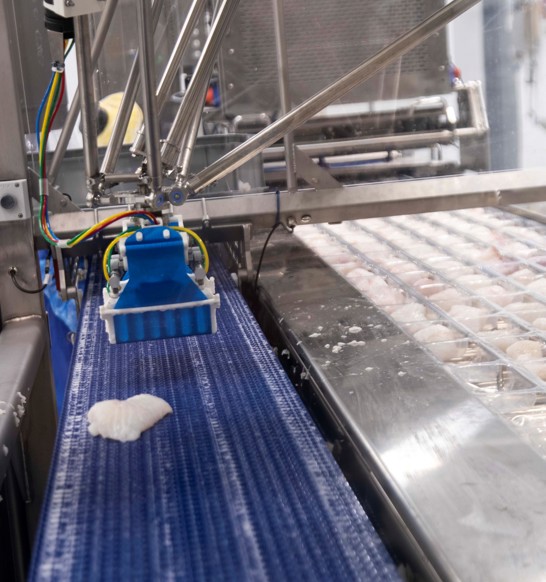

The RoboBatcher Thermoformer packs and styles whitefish portions into thermoformer pockets, directly after cutting. It does it according to precise fixed-weight or catch-weight requirements and a predefined styling pattern.

Fixed-weight and catch-weight packing for retail

The system uses a unique combination of innovative robotic technology and state-of-the-art batching software to create fixed-weight retail packs so close to target weight that giveaway is always minimal. Pieces within particular weight ranges can be diverted into certain packs to meet specific customer requirements, helping you fulfill orders efficiently and cost-effectively. Any pieces that are out of spec can be bypassed, improving quality control. The system can also create fixed-count retail packs, with up to 200 picks per minute, ensuring you get the most value possible from your raw material.

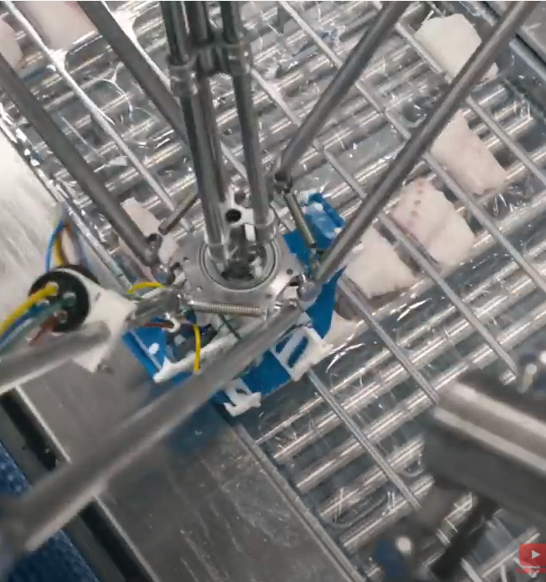

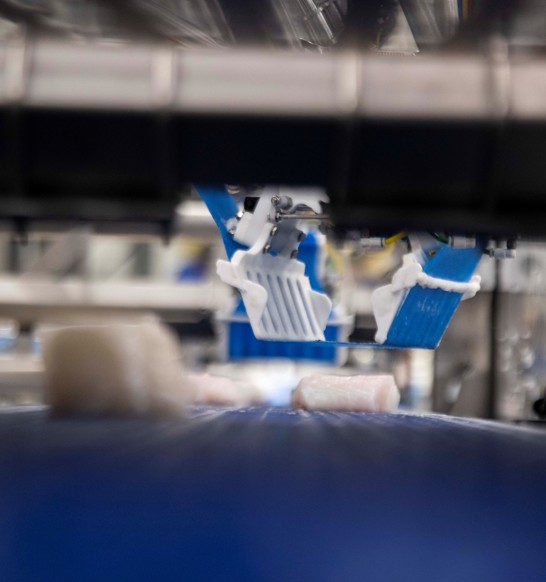

High-speed robotic processing

With unmatched speed and accuracy, the system can process up to 200 whitefish pieces per minute. It has unique grippers specifically designed for gentle product handling, ensuring even the most fragile fish isn’t damaged during packing.

Hands-free processing for minimal manual handling

The system virtually eliminates manual handling from the packing process so you can create whitefish products of the highest quality and hygiene. It also significantly reduces your reliance on manual labor, making your production process more secure and reliable.