Information

Increased product quality and efficiency

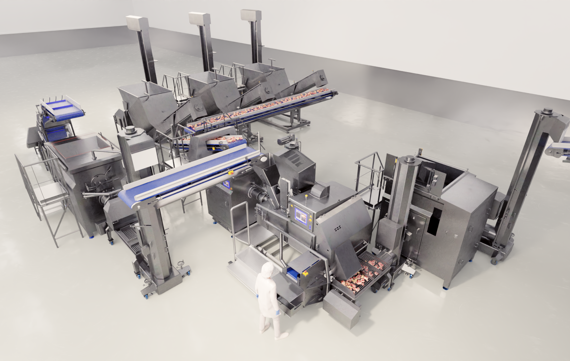

The SensorX Magna is a high-capacity, inline trim inspection system that helps keep your trim bone free and chemical lean (CL) on target. It is a total solution, which scans meat trim and muscles for bones and other hard contaminants as well as measuring the precise fat to lean ratio.

The system lets you make improvements to your mixing and grinding operations which were previously just not possible. It is positioned directly before the mixing and grinding process where it delivers the most impact by monitoring and controlling the CL of raw material as it enters the system.

The SensorX Magna makes it possible to create the correct CL of the final batch right from the beginning of the process. This eliminates the need for costly and time-consuming CL sampling and corrections later in the process.

Superior X-ray technology

What sets the SensorX Magna apart is its superior X-ray technology. All raw material is scanned for density variations and measured for a precise CL. This gives you maximum control over product quality and consistency.

At the same time, it detects the presence of hazardous materials such as bone, metal or glass and efficiently removes the contaminated batch from the process. With growing awareness for food safety, it allows you to meet and exceed safety standards and protects against claims and product recalls.

Improved yield

SensorX Magna has changed the standard of bone detection in both the poultry and meat industry. Finding the bones is half the battle, equally important is the ability to reject the bones in an efficient way.

The system offers a state-of-the-art reject and rework process that minimizes the volume of meat rejected with each bone detected. Utilizing a rotating knife to cut a segment from the product stream ensures that only a small volume of meat is rejected and introduced into a secondary re-work lane. The ability to re-inspect the rejection on a secondary re-work lane further reduces the volume of meat needed to be rejected with each bone detected to around 300 gr.

- Superior X-ray technology for accurate CL measurements and superior contaminant detection

- Advanced reject mechanism for minimized reject volume

- Improved processing for fresh and frozen beef and pork