Information

Strip cutting made easy

The Marel STC StripCutters are easy-to-use meat cutting machines that produces fixed-size portions at high speed. They cut your bone-less and non-frozen products into strips, splits, steaks or diced portions, and are available in 600 and 1000 mm belt widths. You have a vast range of cutting options as a result of easy adjustment of both speed and product width.

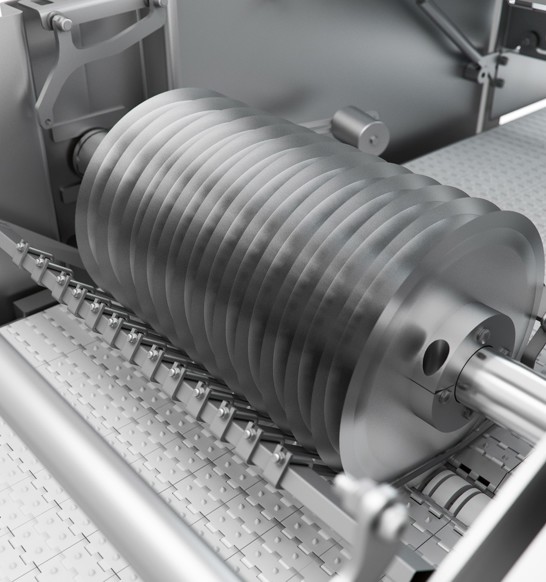

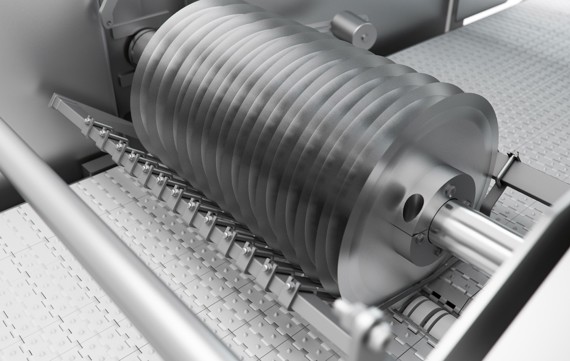

How it works

The infeed conveyor brings the product to the cutting section for accurate portioning size. To minimize giveaway, it is important to position the product correctly at the infeed conveyor. This can be done by using laser indication or stainless steel pointers. The products, which are prevented from moving during cutting, will be delivered on the outfeed conveyor in fixed-sized portions, all ready for packing.

The cutting is carried out by a series of circular blades mounted on a rotating shaft. The distance between the blades determines the size of the portions.

Features

- Multiple products can be cut using the same StripCutter configuration

- Fixed pointers for accurate product infeed positioning–laser or pins

- The moving cutting roller ensures a clean and accurate cut.

- High productivity and continuous product flow - belt speed up to 30 m per minute

- Only one operator needed

- Easy to use: Only a few switches are needed to set up production, adjust the speed of the belt and blades and control the laser light switch.

- Easy to move

- Available in 600 or 1000 mm belt width

- Standard infeed conveyor belt 500 mm. Extended conveyor belts optionally available.

- Hygienic design with soft edges that help ensure easy cleaning and quick drying

- High operator safety–no open cutting areas