Information

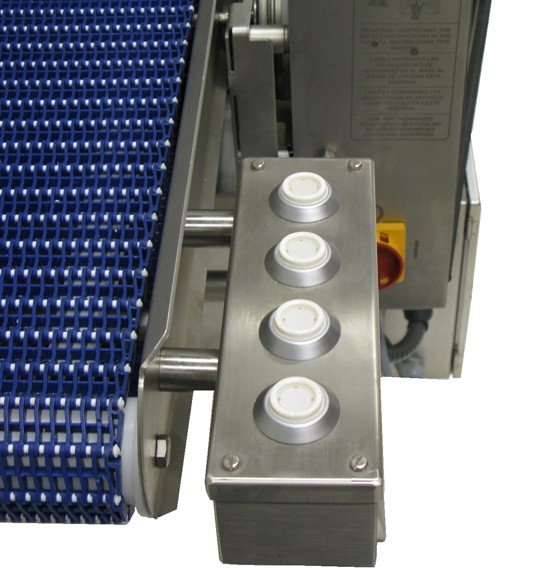

The conveyorized Auto ThinAdjust Shoe Control can be used in heavy applications to remove skin and fat. A series of four buttons are used to automatically set the skinning thickness for a wide range of different sized products, e.g. rose meat, tri-tip, lean upgrade, sirloin, brisket, loin wings. These buttons replace the need to manually turn a T-handle to adjust the skinning depths and can be programmed to four unique skinning thicknesses to meet the customer's growing needs.

Features

- Available in two skinning widths

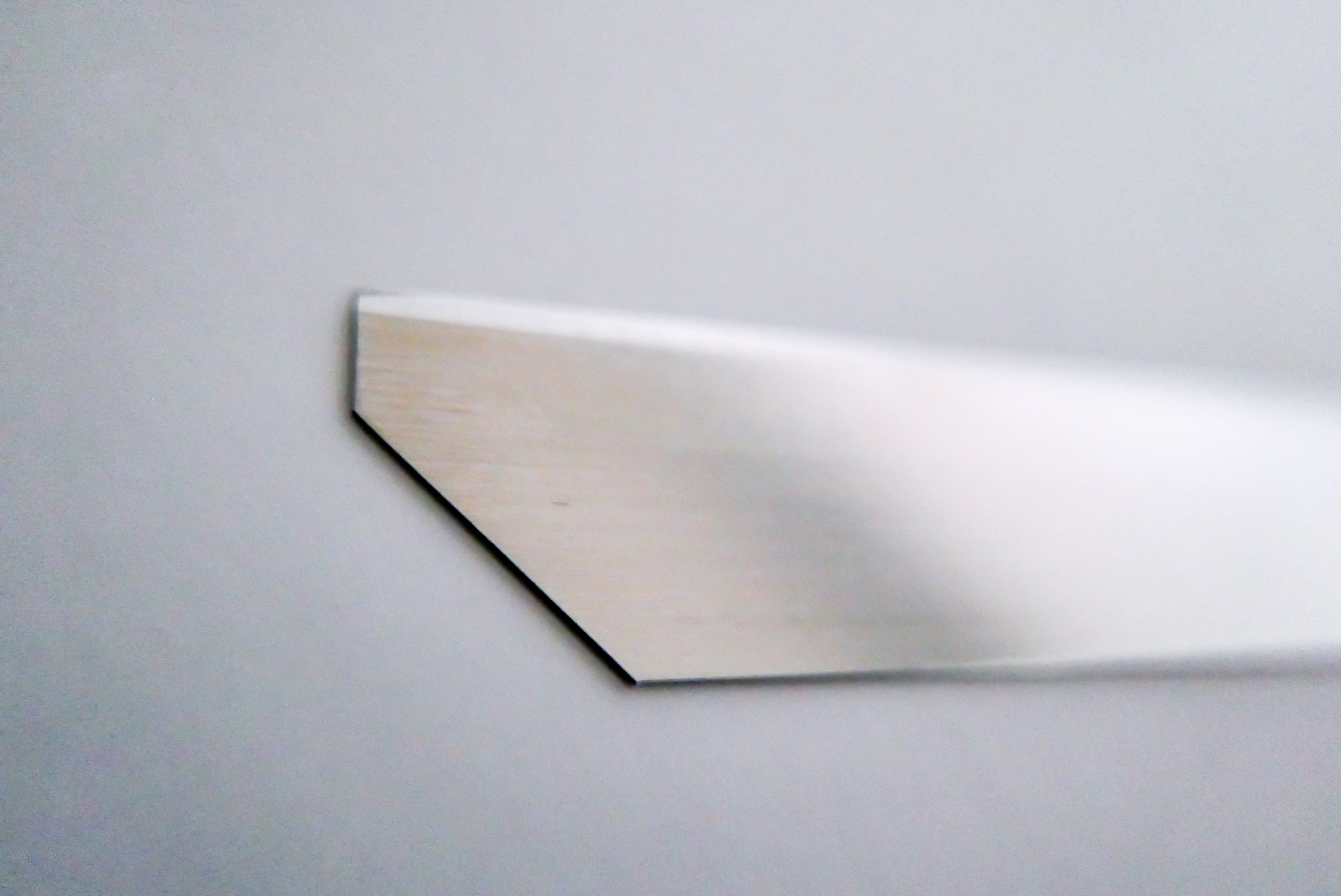

- "Line bored" cabinet creates a perfect alignment between tooth roll and skinning mechanism

- Shoe can remain on the machine during sanitation to prevent damage

- Single drive belt located on one side for easier maintenance

- Adjustable height exit conveyor is ideal for a multitude of production line layouts

- Hood assist to aid in opening and closing of the hood

- Auto ThinAdjust shoe control allows for skinning thickness to be adjusted while the machine is running with a push of a button

- Four programmable button settings for unique skinning thicknesses

- Open conveyor frames for easy maintenance and sanitation

- Low cost of ownership

- Easy to adjust spring top feed cylinders allows for optimal performance on many different products

- Easy to lock down top feed mechanisms