Steadily expanding with a focus on food safety and quality

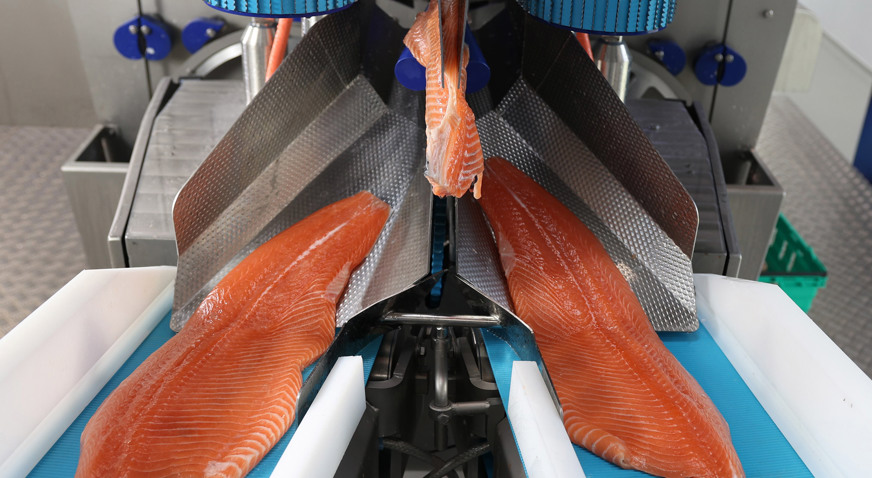

Astafjord has evolved and expanded significantly since it was founded in the 1980s. Starting with modest facilities capable of processing around 3 tons per day, the company has transformed into a large, state-of-the-art plant with an impressive capacity of 150 tons of salmon per day.

With a philosophy of continuous improvement, Astafjord has built a reputation for excellence and innovation. Food quality and hygiene are paramount, as both consumers and the regulatory environment demand that salmon food products meet the highest food safety standards.

Partnering with Marel for full-line salmon processing solutions

Collaboration between Astafjord and Marel began in 2019 with the introduction of a new packing grader for HOG salmon, which boosted efficiency and enhanced packing precision. The partnership has continued to flourish, with Astafjord recently investing in a Marel Satellite Grader for grading fish before filleting.