Meeting the demand for sushi

The consumption of sushi is growing worldwide. In addition to restaurant dining, sushi is now popular as a takeaway meal, and fresh sushi retail packs are available in many convenience stores.

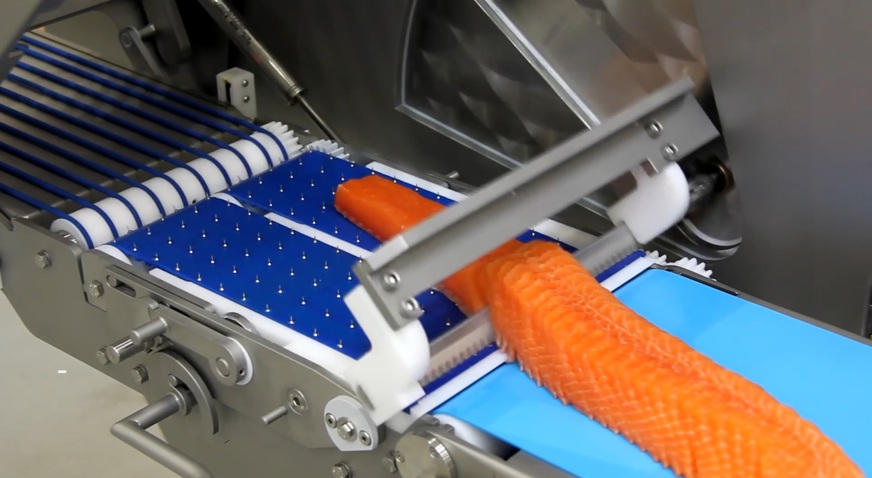

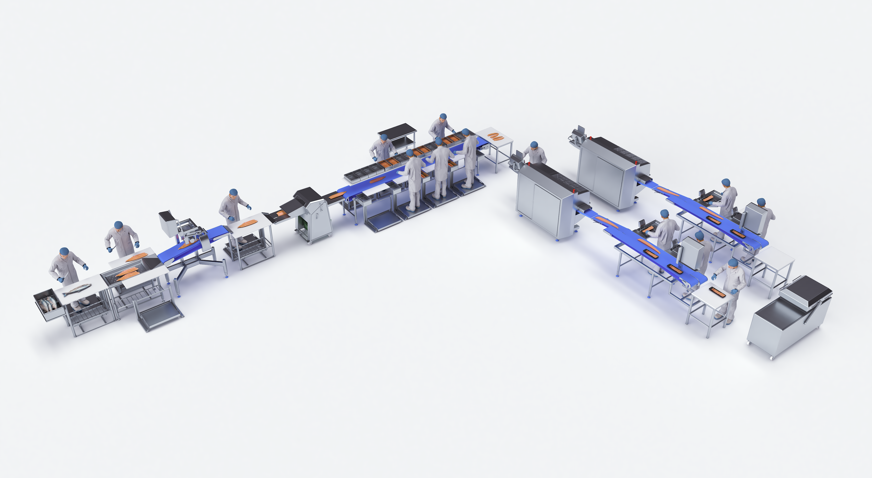

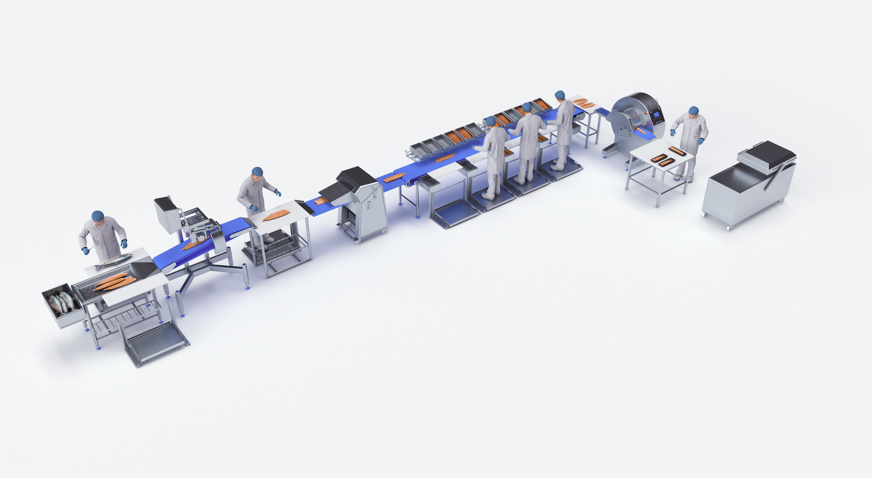

For producers in the sushi sector, the process of cutting fish for sushi has become more important than ever. The new demand for sushi has pushed production volumes up, but the fish is still cut by hand in most places. It takes a long time to train a skilled sushi cutter, and it can be hard to recruit and retain people with the right talent for this difficult and time-consuming work.

Contact us