Ultimately, IRIS FP aims for zero defects.

IRIS FP is a vision quality inspection system designed for further processing lines. Its cameras scan the entire conveyor belt to check every single product. With its objective assessment, IRIS FP provides insight into defective products, enabling processors to pinpoint the cause of those defects and resolve it. IRIS FP is not a reject system, it’s a monitoring system for visual quality that gives early warnings for defects and out-of-spec trends. The ultimate goal is to prevent rejects from happening at all.

Products can be out of spec due to color, size, shape, pollution (black spots), voids, leaking, lips, foreign materials, and more. Previously, operators had to visually assess fast-moving products. This repetitive task required training on the prevailing quality rules. The manual process was prone to errors, highly subjective, and led to inconsistent results.

IRIS FP eliminates human bias and fatigue. It provides continuous, reliable, and uniform product scanning throughout the day, regardless of belt speed, operator skills or conditions. Unlike humans, it scans 100% of products—not just samples—ensuring consistent quality control by precisely following the quality standard rules without generating false positives.

During installation, the IRIS FP system is trained to recognize specific quality standards, by using labeled products and defects as input. This training can include your own unique, customer-specific standards, which are then stored as predefined recipes. It is easy to access or switch between these recipes from the control room or via a tablet computer.

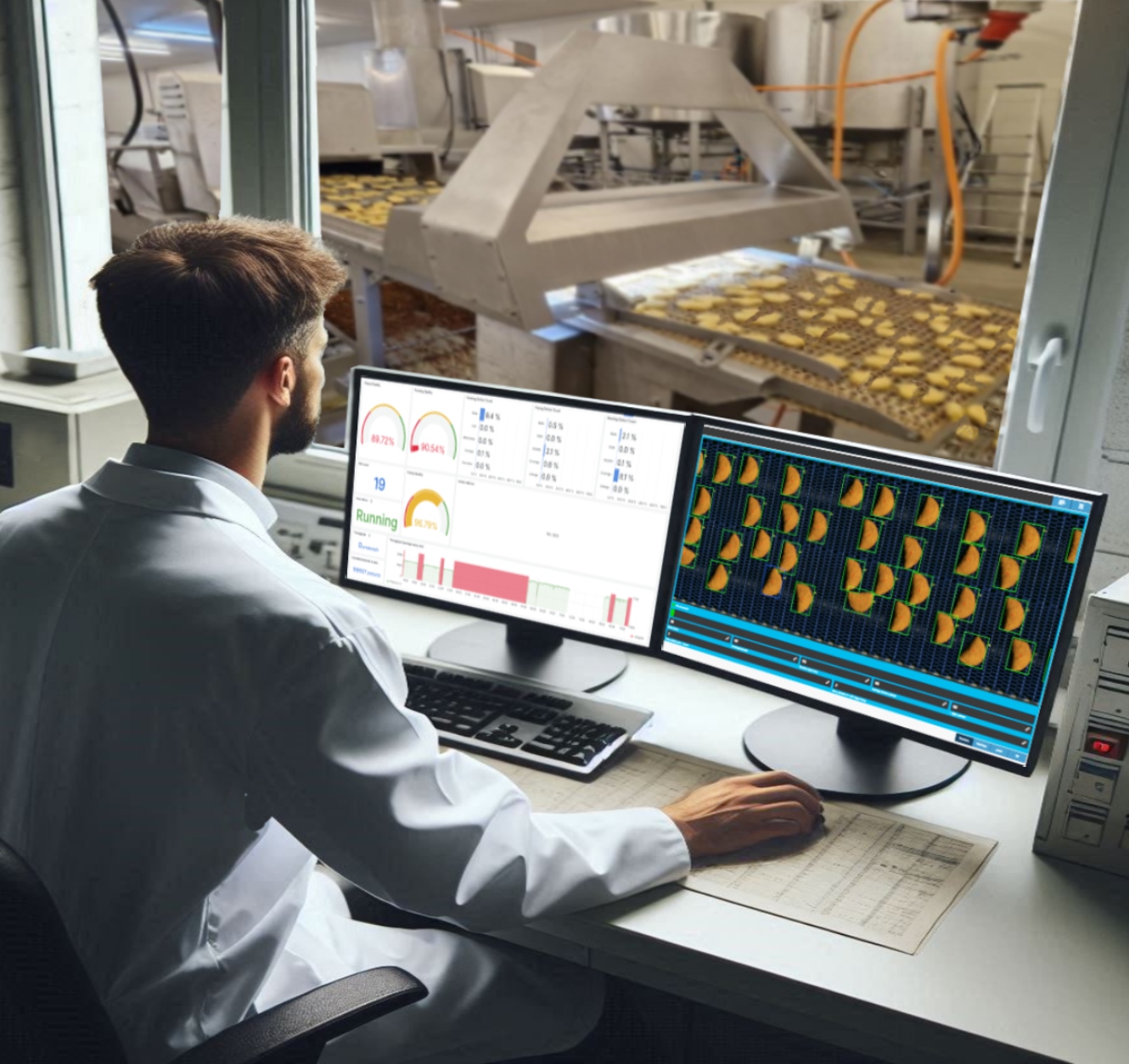

IRIS FP uses its onboard cameras to continuously monitor the passing products. It is possible to view this ‘livestream’, including marked defective products, on a computer screen. Each product on the conveyor belt is counted and analyzed. Using advanced algorithms, every single product is compared to the reference standard, such as the specifications from a QSR chain. Any predefined defects are detected and marked. You can decide for yourself which product pictures and their data (size, color, belt position, timestamp, quality analysis) you store in the database: all products, or only the defective ones. This generated data gives you insight into current product quality, deviations from standards, trend analyses, and predictions of potential out-of-spec issues.

IRIS FP will be compatible with all belt widths and can be installed at four strategic points in the further processing line: after the forming machine (RevoPortioner), coating machine, fryer, or oven. At each stage, it detects processspecific defects, so for full visual quality control, all four positions have an IRIS FP. For example, if the former drum isn’t cleaned properly, it may not release formed products correctly. IRIS FP will detect an excessive percentage of holes in the products and display a warning on the screen. Similarly, but with different parameters, after the fryer, it can spot leakages in products like cordon bleu. The more IRIS FP quality checkpoints you install along the line, the better your ability to detect defects and out-of-spec trends. This also allows you to pinpoint more precisely where issues occur. On-screen and traffic light warnings will alert the line manager, who can then identify the issue and improve the upstream process. All this will lead to a reduced number of B-quality products and minimized product loss and waste. Production quality and profitability–with A-quality products only– will benefit from this.

IRIS FP’s internal software generates trend analyses and detailed reports, which you can use, for example, to address unjustified customer complaints about product quality. Other reports may provide a production overview per product over several days or a production review of a specific day when an incident occurred.

IRIS FP can also give ‘trend warnings’ when products gradually approach critical specification limits. It alerts the line manager in advance, enabling timely upstream adjustments to prevent products from really going out of spec. This is very useful to prevent a prolonged production of defective products, saving rework and waste due to fewer rejects and no spilled coating, water and energy.

Ultimately, IRIS FP aims for zero defects.

IRIS FP eliminates the need for operators to perform assessments, requiring them only to remove defective products—which will decrease in number. The reduced waste and rework enable more profitable processing with virtually no false positives or defects in final packages, minimizing recalls and complaints. Ultimately, IRIS FP aims for zero defects with minimal operator involvement, ensuring a fully automated process with no rejects.

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.