Information

Precision cutting for maximum yield

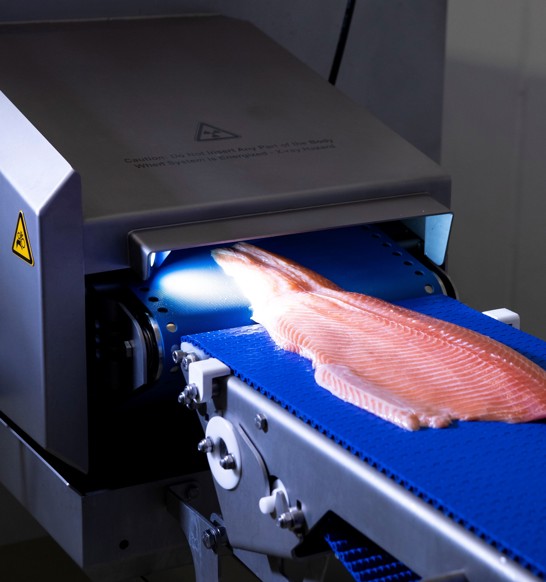

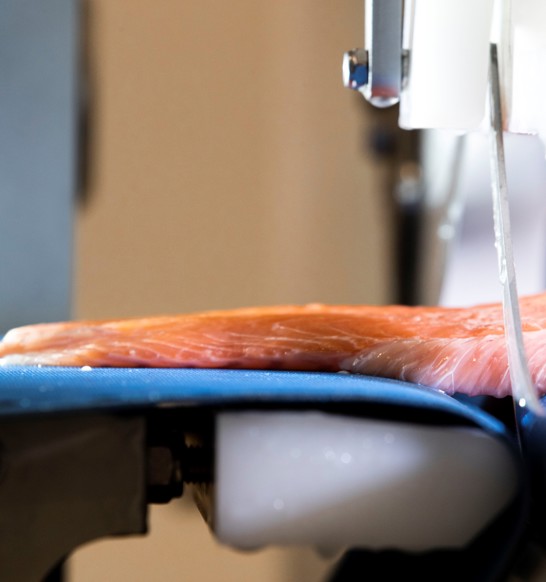

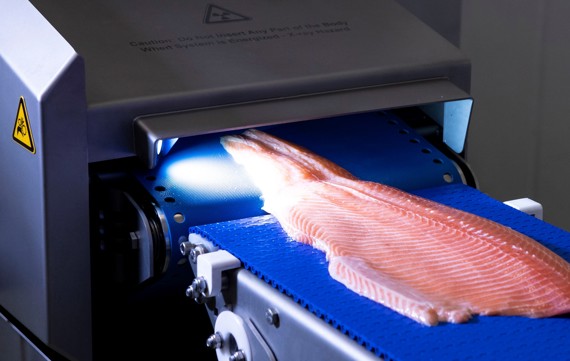

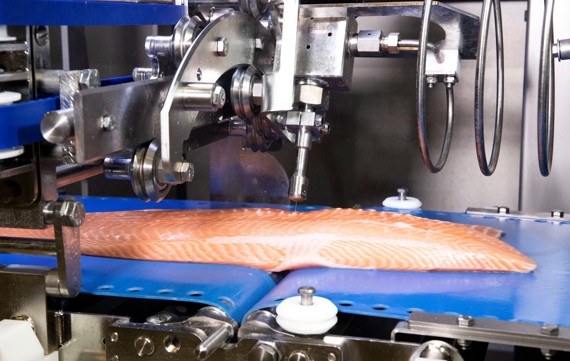

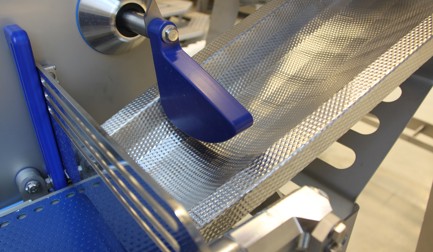

FleXicut Salmon consistently ensures maximum yield by adjusting the cutting angle according to the precise location of the bones each time, using both water-jet cutters and knives to portion the salmon.

It uses X-ray vision to locate the bones and ensures minimum yield loss by adjusting the water-jet cutting angle to remove bones according to their precise location each time.

Top end-product quality

FleXicut Salmon is designed to ensure the best utilization of each and every fillet. It detects even the very fine end of pinbones and delivers superb product handling for optimum end-product quality.