Information

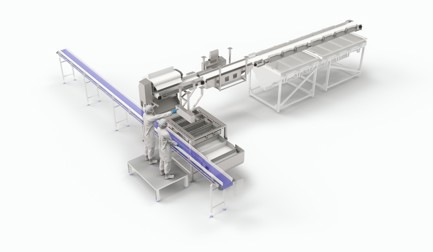

The Whole Fish Grader system is for the onshore size grading of fresh whole whitefish such as cod, haddock, and pollock/saithe into tubs and/or boxes.

Better handling, higher value

The system grades fish by size, enabling better handling of the raw material in the following process steps and resulting in higher product value. The Whole Fish Grader enables you to increase yield by optimizing the settings of filleting and deheading machines.

Improve stock management

With the Whole Fish Grader system, you know the weight distribution of your stock and can report to your customers how much volume of an end product of a certain size you will be able to produce.

Easy and accurate accounting

The Whole Fish Grader gives you the information you need—total weight, weight distribution, and number of pieces—in order to deliver accurate quota accounting, as well as settle accounts accurately with supplying vessels.