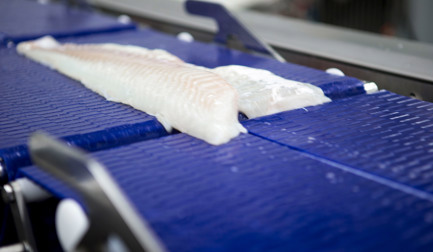

The new FleXicut Jet is unlocking unmatched efficiency, reducing handling and cut waste while enhancing fillet yield and quality.

New waterjet cutter FleXicut Jet

Quality scanning of salmon

Explore the new features and design of the MS 2920, setting new standards in salmon fillet quality control

A new era of salmon filleting is launched with the MS 2750

Extraordinary durability, flexibility and connectivity take salmon filleting to the next level

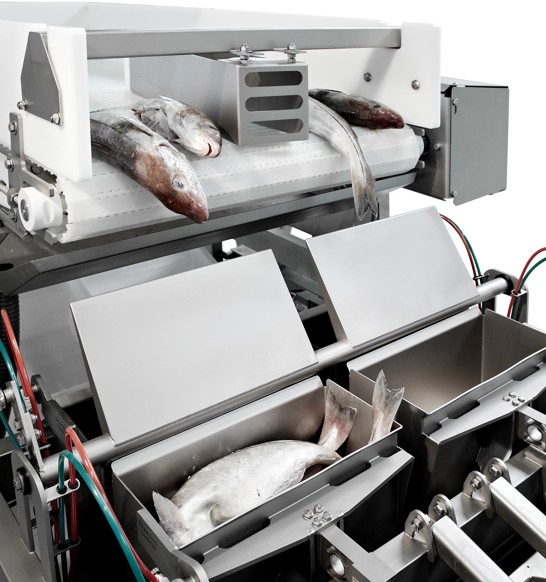

Innovative solutions for fish processing

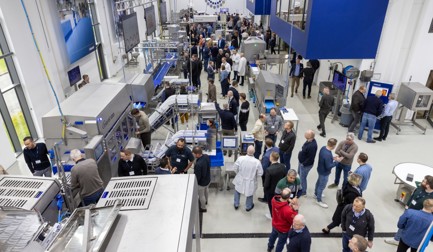

At the forefront of fish processing

Marel is the leading global supplier of advanced standalone equipment and integrated systems to the fish industry. Whatever your organization’s size or objectives, we have the products and expertise to help your business thrive and become more sustainable.

Choose your species:

Marel Food Processing Software

Marel Software enables food processors to collect and utilize data effectively, improving processing results and ensuring full traceability throughout the production process.

Service

Marel’s service solutions are tailor-made to suit your specific needs. Each solution is tailored to the site and production specifics, to maximize productivity across the production line.

Our global service network takes the worry out of maintenance, making sure your operation remains optimized and competitive. We are always striving to enhance our global reach while never compromising on our local service relationships.

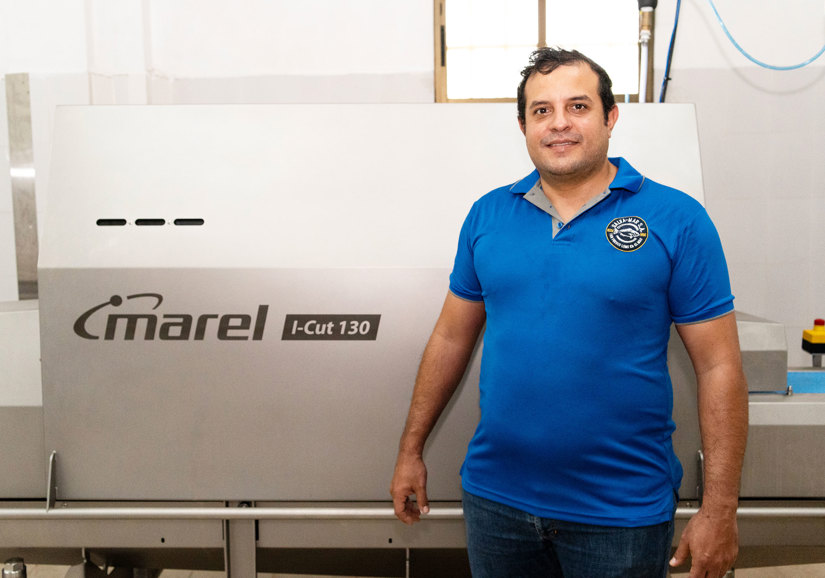

Wherever you are, Marel’s sales and service specialists are close by and ready to help.