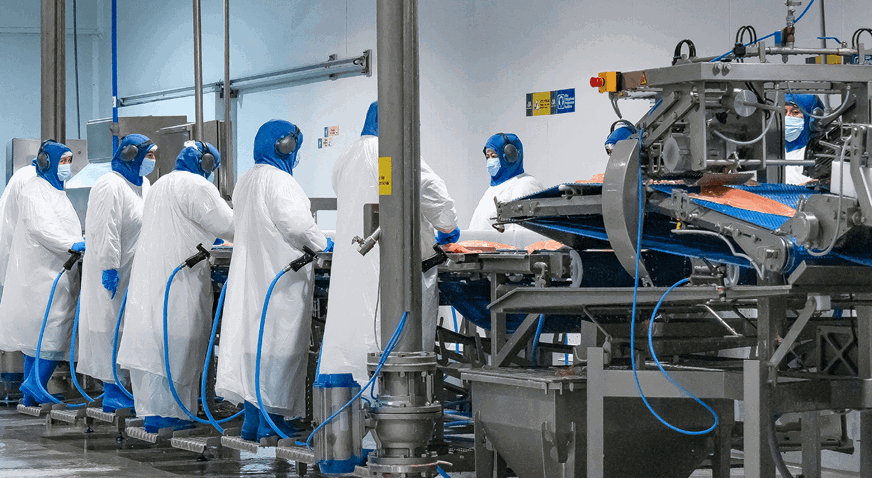

For Chilean salmon processing company Alvarez y Alvarez, innovative technology and infrastructure have been key in their growth and success. Founded in 2008 by brothers Eloy and Orlando Alvarez Navarro Oyarzun, the company has grown from a modest 600 m² processing plant into a modern 5,500 m² facility equipped with advanced Marel solutions. We had the opportunity to speak with Rodrigo Torres Oyarzun, Process Manager at Alvarez y Alvarez, who shared insights into the company’s journey with Marel, highlighting their recent investment in a MS 2750 filleting machine.

From crustaceans and shellfish to salmon processing in the Patagonian fjords

Alvarez y Alvarez’s facilities are located in Puerto Natales, a southern coastal city in the Magallanes Region of Chilean Patagonia. Although this region offers excellent conditions for salmon farming, it has not traditionally been common there. When Alvarez y Alvarez was founded, its focus was on seafood such as sea urchins and king crabs, before they pivoted to specializing in salmon processing in 2015. Today, they produce 3,000 tons of whole fish equivalent (WFE) per month. Fillets make up the majority of their product range, alongside whole salmon and portions.

Alvarez y Alvarez takes pride in their innovative spirit and passion for technology, qualities that have helped the company achieve outstanding efficiency and product quality for their customers worldwide. They serve clients across the USA, Latin America, Europe, Asia and the Middle East, including those in the wholesale market, restaurant chains and retail outlets.

Pioneering in partnership with Marel

Alvarez y Alvarez first turned to Marel when they transitioned to specialized salmon processing and needed to transform their facilities. With Marel solutions, the company expanded to serve salmon farmers in the Magallanes region who did not have their own plants to process raw materials. As Torres Oyarzun explains, “The Magallanes region before 2013 was characterized by being a non-salmon farming area, so there is a shortage of specialized direct labor. In this regard, Marel has solutions to automate processes that would normally require a large amount of specialized personnel.”