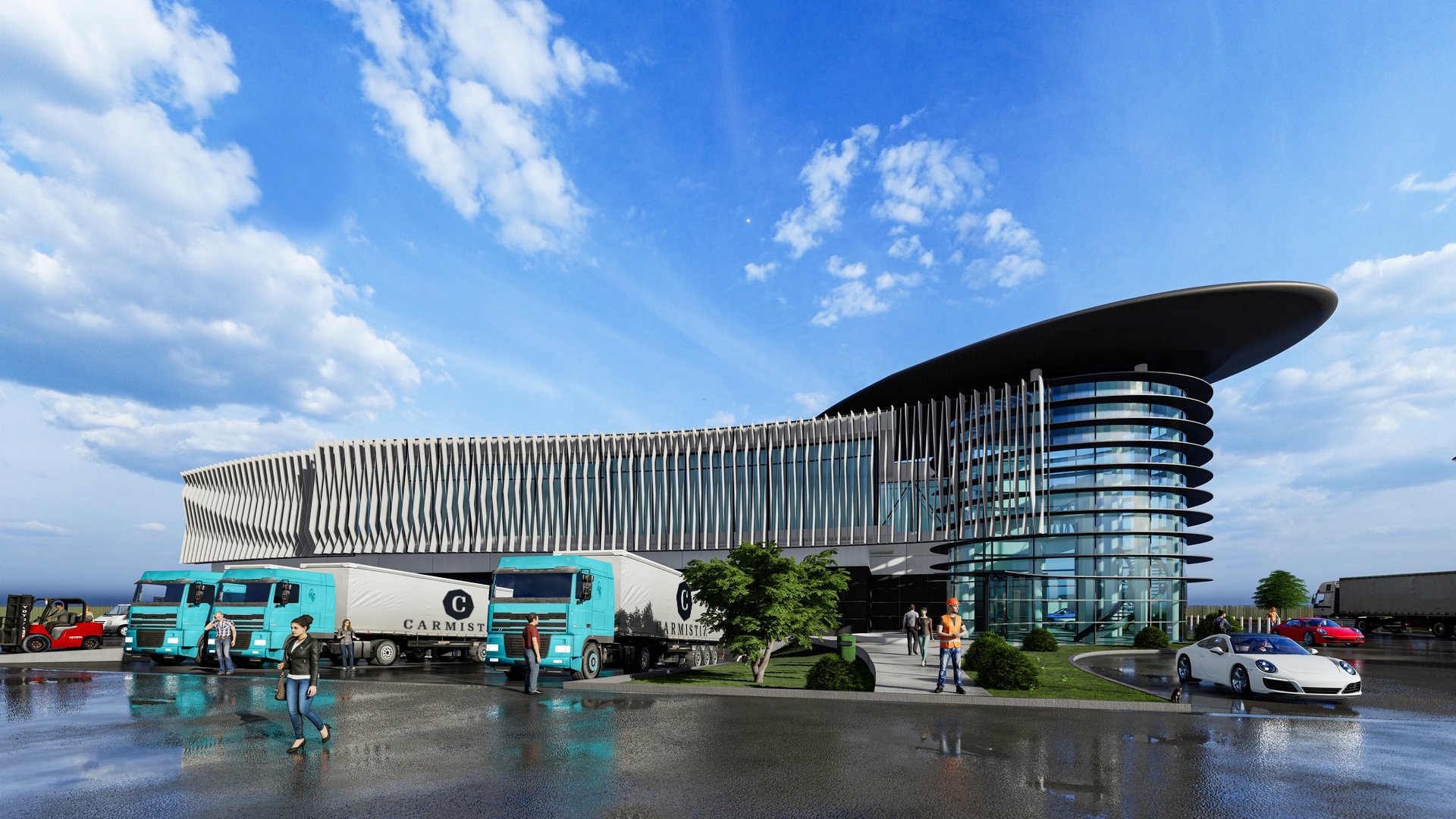

In Vâlcea County, Carmistin will build the most modern poultry processing plant in South-Eastern Europe. Covering an area of 25,000m2 [6.18 acres], it will be the largest chicken meat production unit in Romania and will have Marel as its main partner. Andrei Brumaru explains, “Given our sales forecasts, we need to expand. At the same time, we want to ensure our competitiveness against the international competition, producing more chicken of higher quality. For the best results and the best return on our investment, we decided to cooperate with Marel.”

First choice

“Our first contact with Marel dates from when we purchased our second processing plant in Targu Jiu. It features Marel systems in the primary process, from killing to chilling. For our future greenfield plant, we compared the efficiency of the lines in our two existing processing plants. Marel’s line was clearly superior. Marel was therefore our first choice to equip our third processing plant, which is projected to be functional by 2023. This factory will have a capacity of 13,500 bph [225 bpm] and we will work two shifts.”