Information

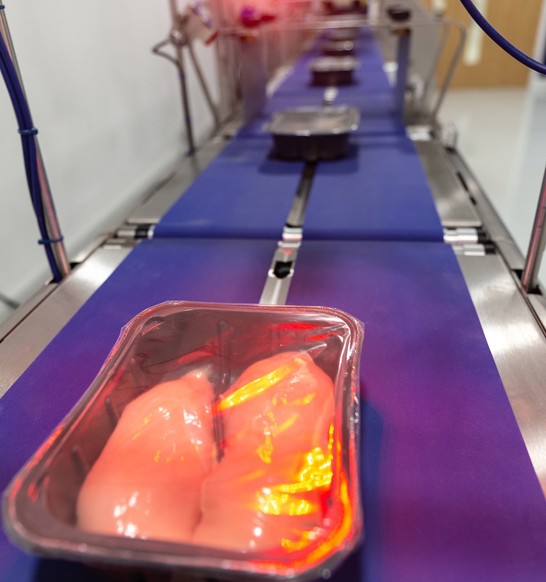

The WPL9000+ is a high-speed, approved weigh price-labeling machine, which applies printed, self-adhesive labels with either catch-weight or fixed-weight information to packaged food products.

Flexible labeling

Labels can be applied to any surface of a product. WPL9000+ prints multiple 1D/2D barcode formats, weighing data, clock-linked dates and all relevant product information in multiple languages.

Contact applicator

The label applicator can be equipped with a contact applicator to label uneven surfaces. It then applies labels by direct light contact with the pack and releases the label after placing it precisely.

Class-leading design

The WPL9000+ employs the latest technology and class-leading design to provide excellent performance at a competitive price.

Its compactness is a big plus as it only requires a small footprint in the factory. Nevertheless, its construction is robust with high-quality materials, hence longer lasting and resulting in a lower cost of ownership.