In 2019, China’s pork consumption dropped by 15%, driven by food safety concerns, which were mainly ASF related. Outlets serving consumers as well as catering for schools, factories and large companies have shifted to other animal proteins such as poultry. Chicken breast meat, used a lot in meat processing and food service, has seen large price increases.

Dramatic upgrade

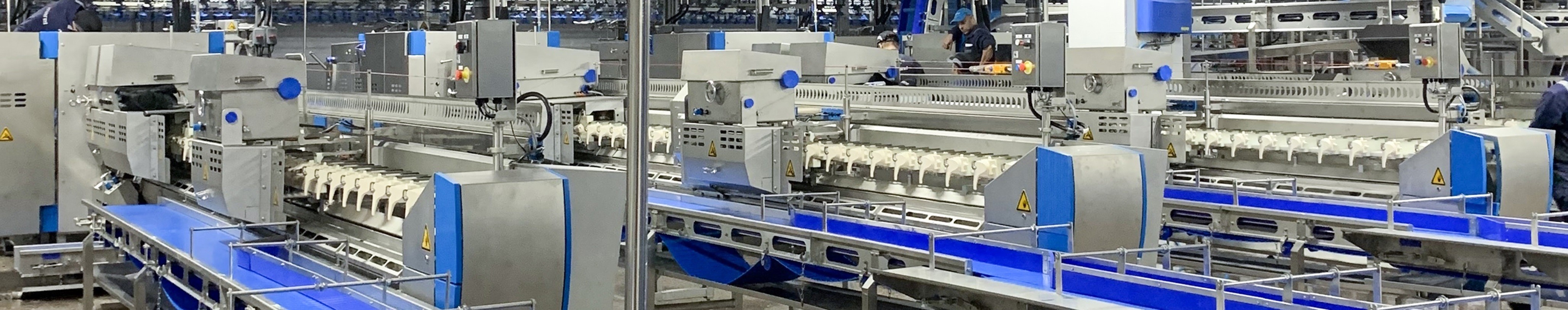

Following the dramatic market shift, CP Food was looking for ways to expand its LongYan Chia Tai poultry processing plant. The aim was to increase processing capacity while improving production efficiency, reduce dependence on manual labor and drive down production costs per kilo of poultry meat. This meant a considerable increase in automation and a higher level of product quality. LongYan chose Marel as its exclusive partner for replacing existing machinery and manual labor with the necessary automation upgrades. “To achieve LongYan’s upgrade to 13,500 bph, we replaced a lot of existing equipment, particularly in the evisceration, distribution, cut-up and filleting departments,” says Kai Zhao, Industry Sales Manager Marel Poultry. “Now, the processing line meets all requirements regarding automation levels, production efficiency and product quality.”

Speed and tension

An important upgrade involved the Sigma overhead conveyor line running through the entire factory. It has a total length of about 500 meters and is controlled by ATC automatic tension control, Marel’s unique way to check chain performance. For data acquisition and the logistic control of all processes taking place in the overhead conveyor, Marel supplied its Innova PDS software.