At the time of the first meetings between Marel and Yunken, broiler processing automation in the Northeast of China was not widespread and manual production lines were still the norm. The Yunken Group is aware that automation is the future. It therefore plans to gradually upgrade and convert all its manual broiler processing lines into automated processing lines. The Yunken Changchun plant was to be the first pilot project.

Performance and quality compared

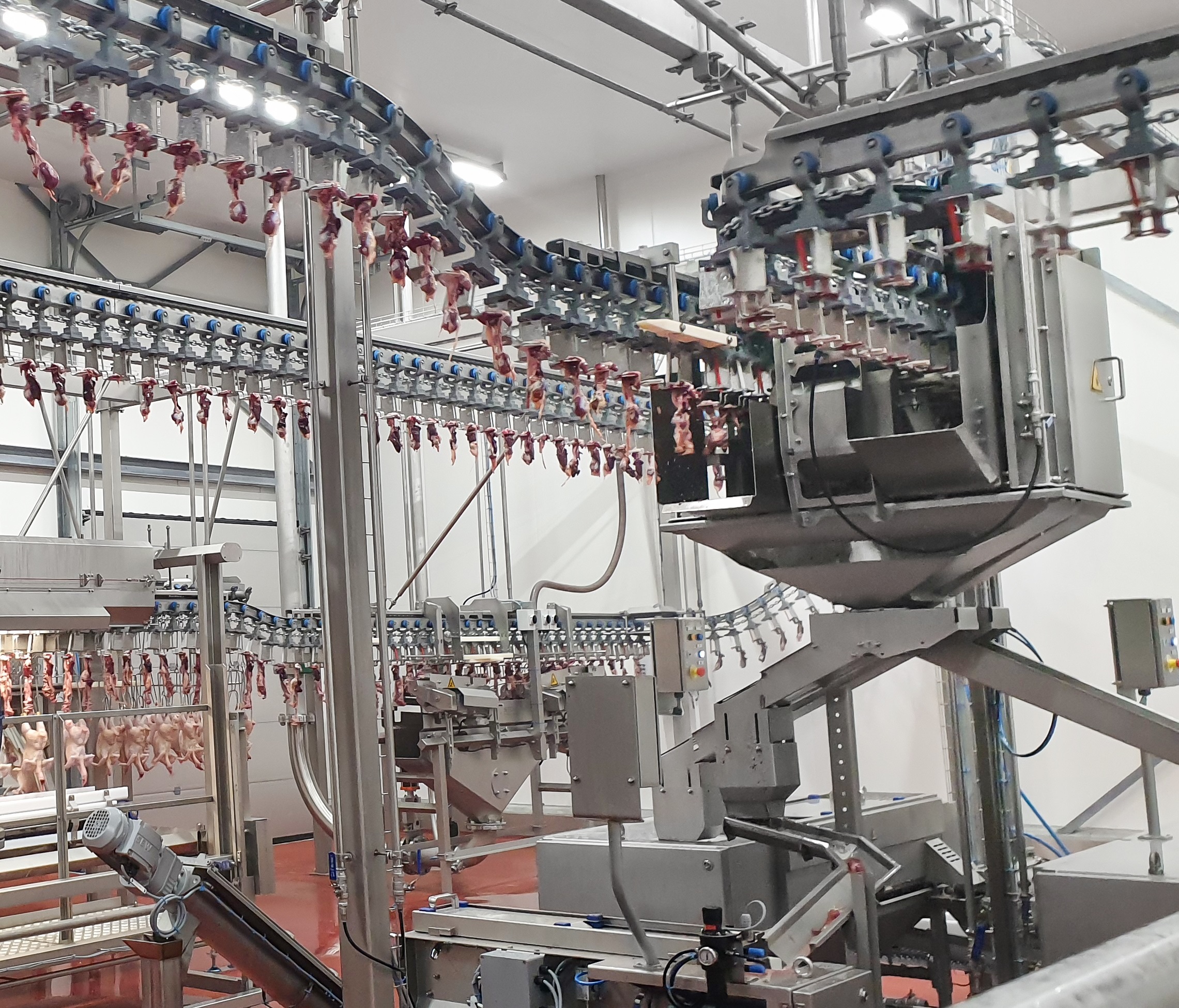

“We investigated in depth and in detail, communicating and discussing with others in our industry. We compared equipment performance and the quality of products made with it. Having learned about the comprehensive advantages offered by Marel poultry processing solutions, we finally chose to cooperate with Marel. We decided to start by upgrading the existing manual line in the Yunken Changchun plant to a 13,500 bph [225 bpm] production line including automatic evisceration and giblet harvesting,” says Mr. Zhao Xiaoguang, Chairman of the Board of Directors of the Yunken Group. In the meantime, the line was installed and commissioned earlier this year. Everything went smoothly, although Covid-19 meant that Marel’s Chinese engineering team had to operate independently without the on-site support from Marel experts from abroad. They were not able to visit China due to travel restrictions. In the end, successful commissioning happened even sooner than expected.