Informed decisions

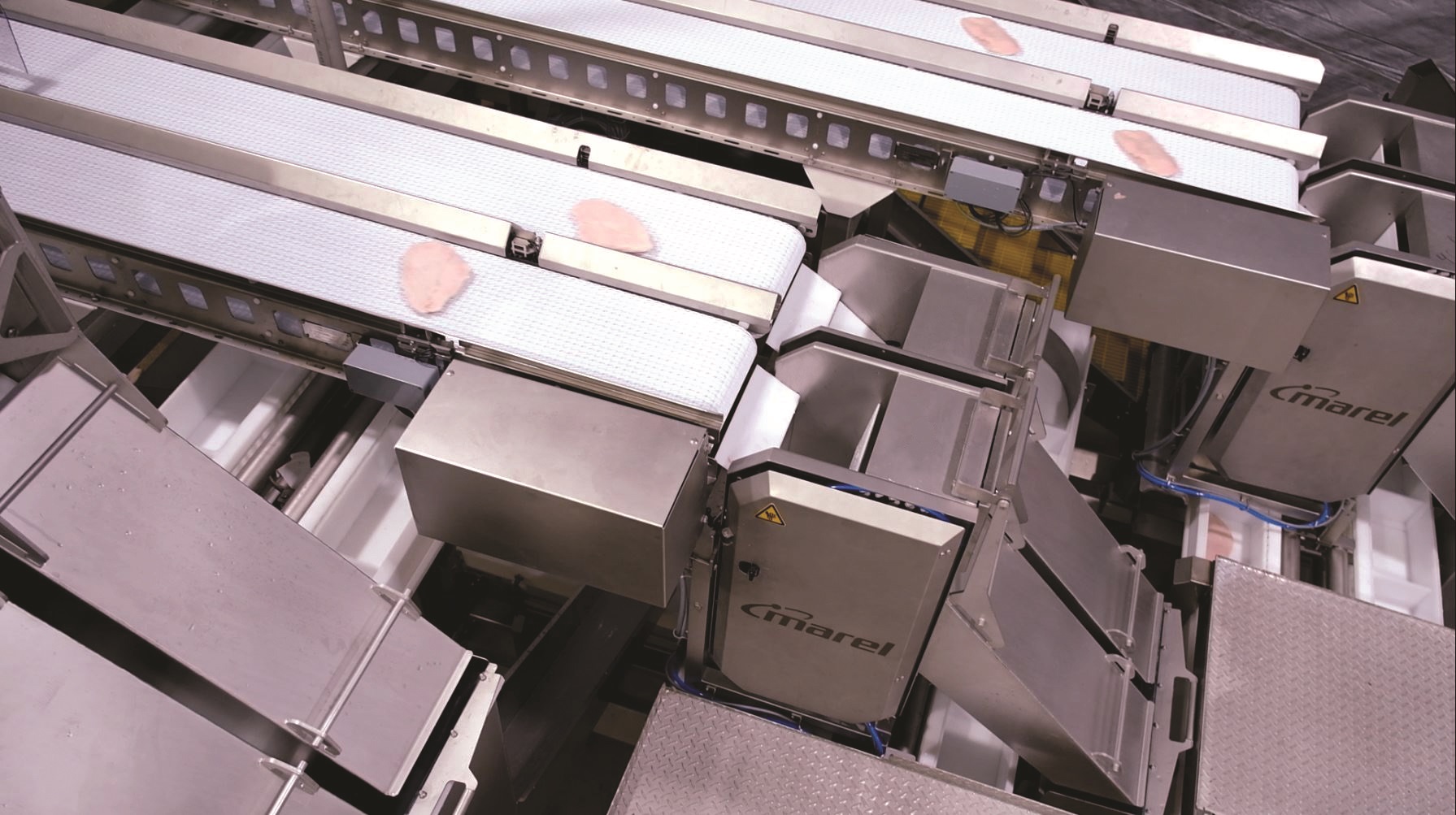

The nature of the production process meant that all systems needed to be able to communicate with each other. Innova achieves this by managing all distribution processes, intelligent combinations and communication between the various machines. “Integration of the graders into Innova allows us to make informed decisions and adjust processes to optimize the efficiency, control, and quality of our processes. Everything is closely connected to our Innova software and our control tower. This control tower allows us to make real-time decisions, using indicators such as processing, bird status, product weights, and video analysis. It also enables us to monitor and supervise the performance and consistency of our plants,” says Álvaro Ortiz.

Significant success

According to Álvaro Ortiz, the project has yielded significant results across several key areas. “Our primary goal has been met: we have effectively boosted our overall production capacity. The improvement in precision we’ve achieved in our processes is remarkable. Previously, operating at high speeds led to a considerable number of rejected products, necessitating reprocessing. Today, improved accuracy has effectively reduced rejects and the costs associated with reprocessing. Aligned with our commitment to continuous improvement, this project helped us integrate advanced technology and optimize processes.