The Industrial Revolution Reimagined

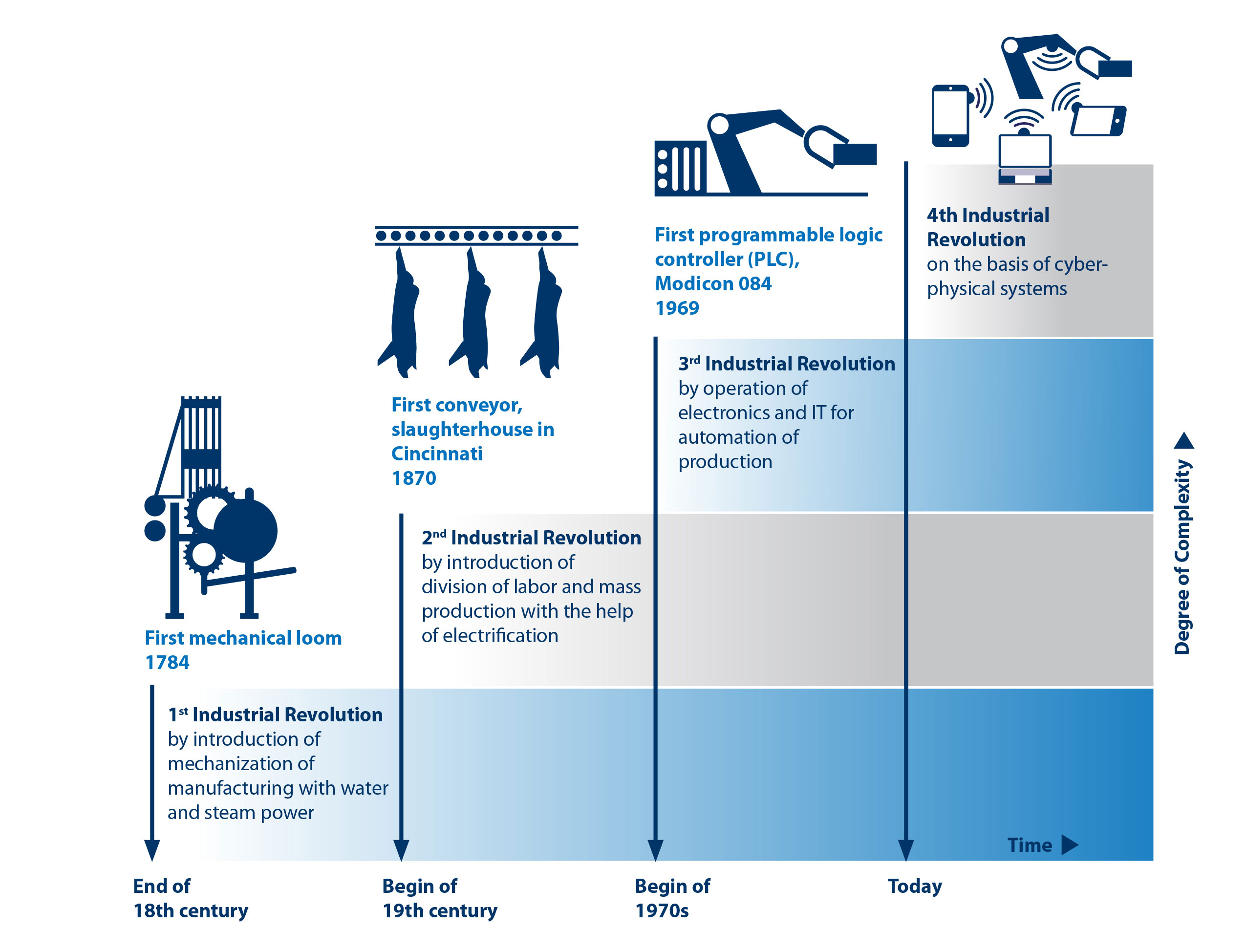

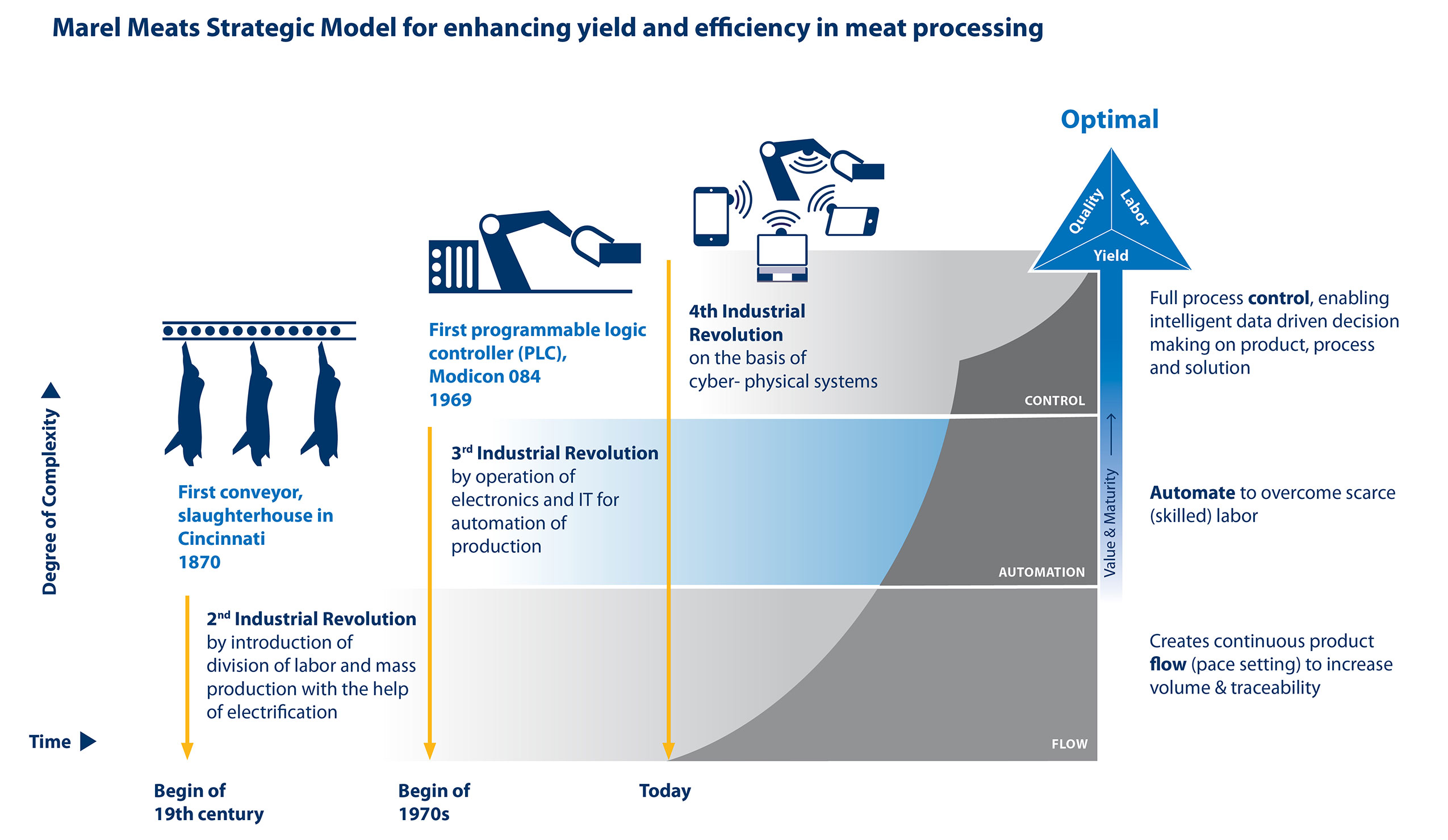

Marel’s innovation model reflects the evolution of industrial revolutions—from mechanization to smart systems. The first industrial revolution introduced basic mechanization, while the second brought electrification and mass production. The third added automation through electronics and IT. Today, the fourth industrial revolution—powered by cyber-physical systems—is driving smart factories.

In earlier times, meat processing was a local and manual practice. Before the Second Industrial Revolution, butchering was primarily done at home or by small butcher shops serving local communities. Families would raise and process their own livestock, while butchers played a crucial role in supplying meat to nearby markets. With industrialization, the rise of large-scale slaughterhouses and meatpacking plants transformed the industry. The introduction of the assembly line in the late 19th and early 20th centuries—most notably in Chicago’s meatpacking industry—paved the way for more efficient and centralized meat production. Refrigeration and improved logistics allowed meat to be processed at scale and distributed over long distances, fundamentally changing how meat reached consumers.

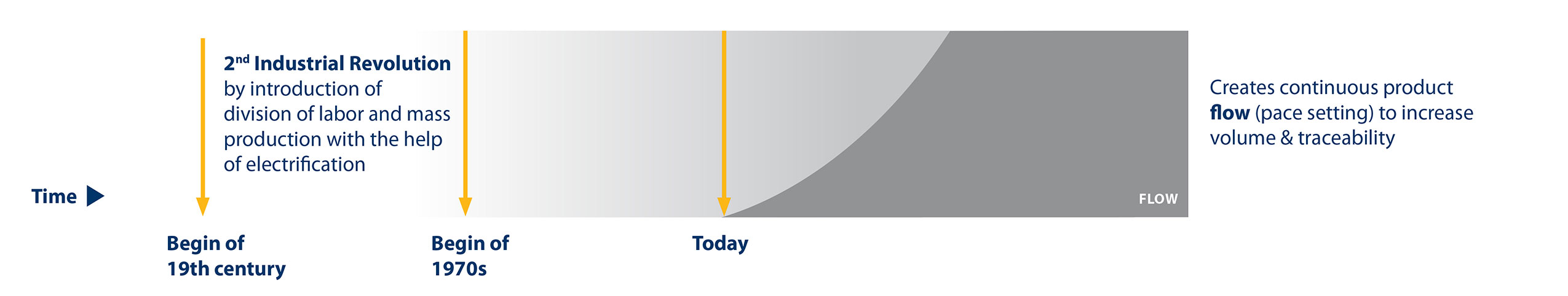

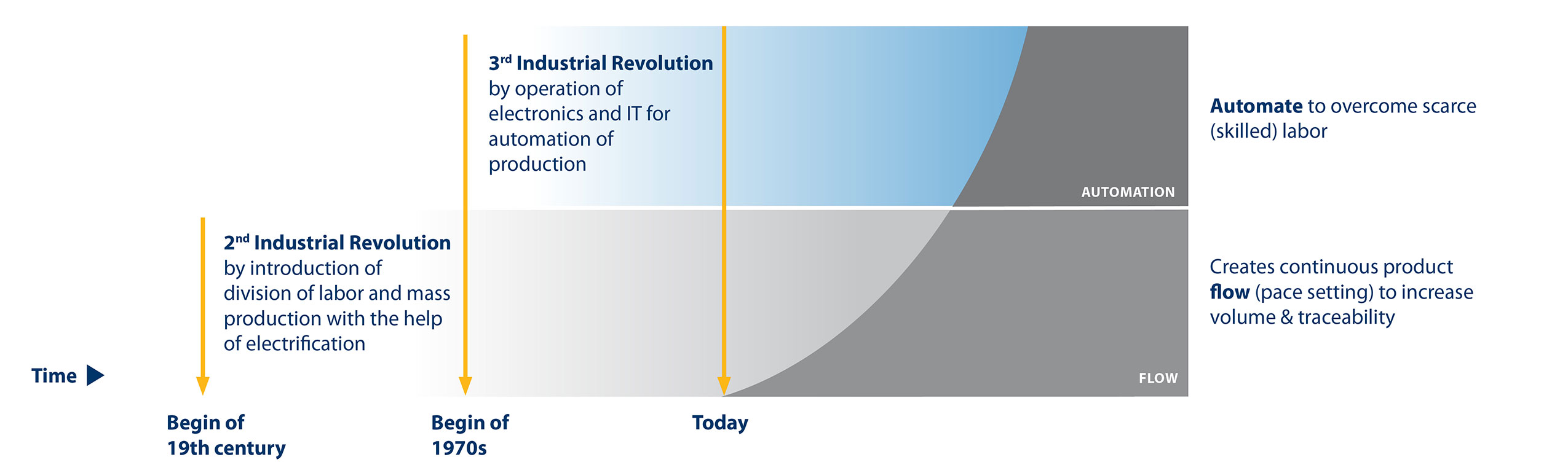

Today, this transformation has advanced even further. What began with simple conveyors has evolved into fully connected, data-driven operations. Marel’s approach highlights how flow, automation, and control are interdependent. By creating a smooth flow, introducing automation, and enabling control through digitalization, processors achieve optimal yield, quality, profitability, and reduced labor.