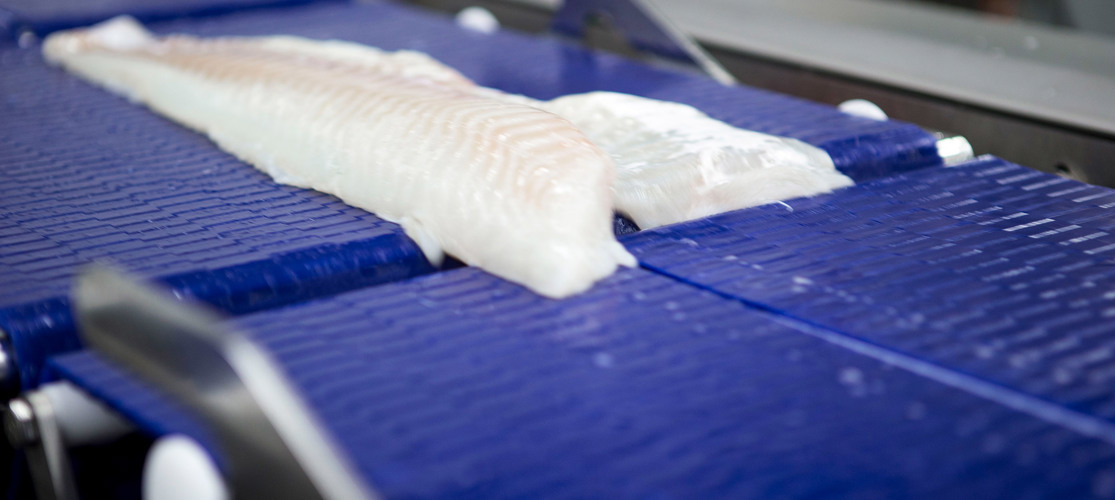

It began with the belief that, just because a filleting machine is good, doesn’t mean it can’t be better. Curio invested knowledge and skills into developing the Curio Fish Filleting Machine. The consistent, steady knife speed creates a cleaner cut, improving the appearance of the finished product. Along with better cutting the design focused on being dynamic and adaptable, resulting in the single machine concept with an adjustable frame. Conversion kits enable processors to fillet fish from 400 g to 16 kg in size, while the ability to fine-tune with an adjustable saddle speed and the like, means the one machine can meet the filleting requirements of different species. This flexibility allows for expansion and changes in processing capabilities, securing longevity of the initial investment.